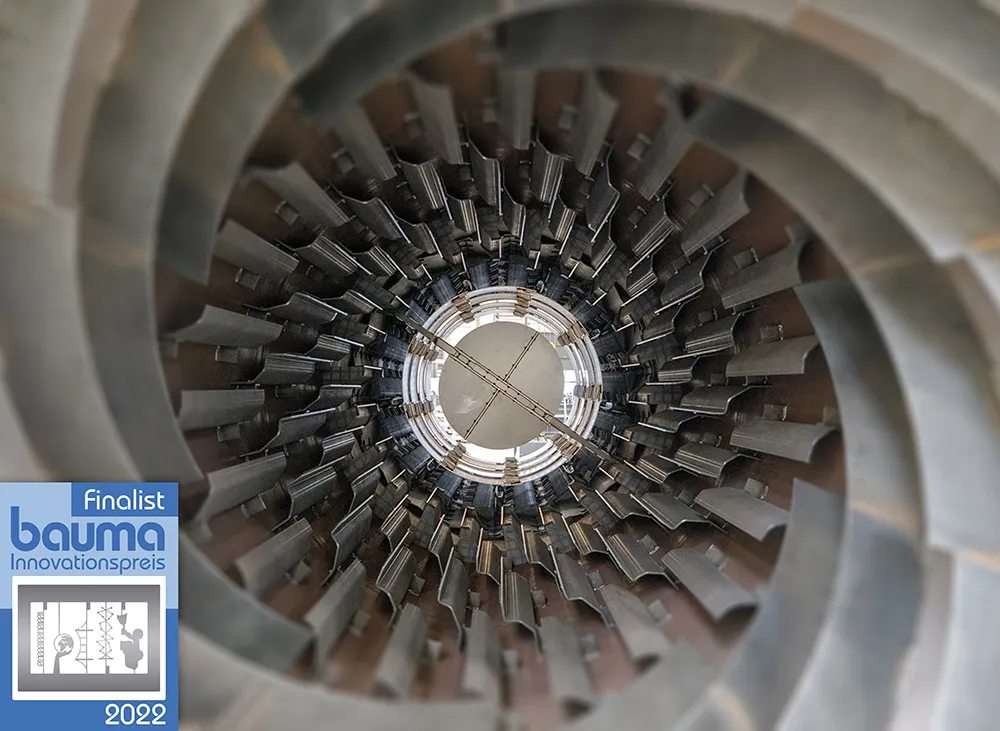

Zoomlion was very proud to show off its new two-in-one systems solution dry mortar mix plant at bauma 2014 held in Shanghai, China. It is a product of Zoomlion's purchase of German dry mortar equipment producer M-TEC late last year.

By using manufactured sand instead of river sand it eliminates the drying stage so drastically reducing both infrastructure and production costs. Zoomlion is very keen to emphasise the environmentally friendly green credentials of the product. "It represents the future of the

January 6, 2017

Read time: 2 mins

By using manufactured sand instead of river sand it eliminates the drying stage so drastically reducing both infrastructure and production costs. Zoomlion is very keen to emphasise the environmentally friendly green credentials of the product. "It represents the future of the industry," said Su Zimeng, secretary-general of

It is available as a tower, station or multi-step structure. The two-in-one system overcomes the problems of conventional mixing such as the inability to recycle resources, lack of sand resources and severe pollution. Zoomlion claim the two-in-one solution can reduce commercial mixing costs by $6.19/tonne and dry mortar costs by $3.10/tonne.

The introduction comes at a time that Zoomlion has moved to broaden its field of operations to include areas such as environmental protection and heavy duty trucks.