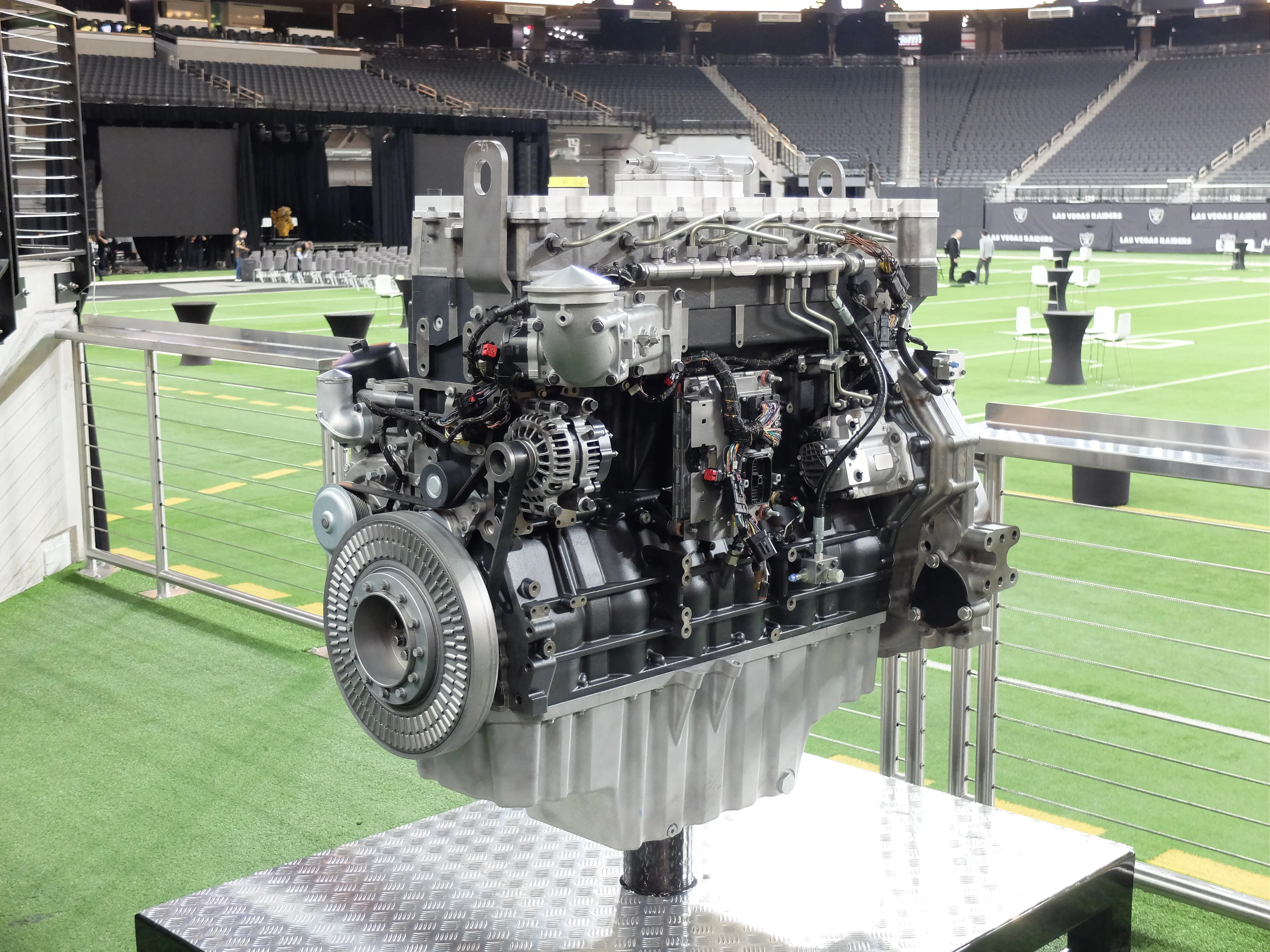

The hydrogen excavator conversions mark the first application of Zepp's fuel cell systems in the construction equipment industry.

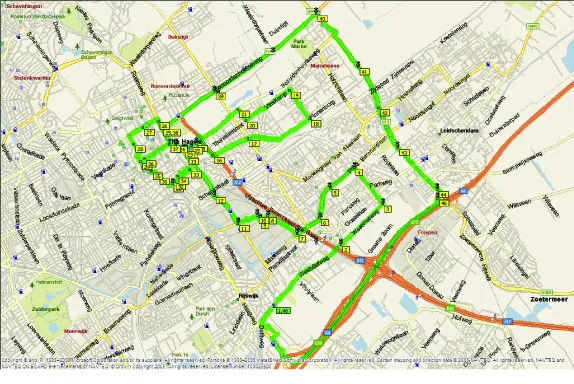

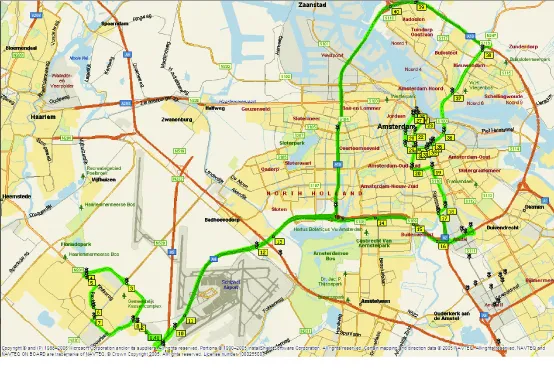

The two excavators, both owned by Dutch contracting company Jos Scholman, have undergone six months of successful operational testing.

Conversion specialist Terberg Techniek, based in IJsselstein, Netherlands, developed the conversion kit surrounding Zepp’s fuel cell systems. Use of this kit is not limited to this type of excavator; Terberg Techniek also plans to use it to convert other construction equipment from a diesel to a hydrogen-electric powertrain.