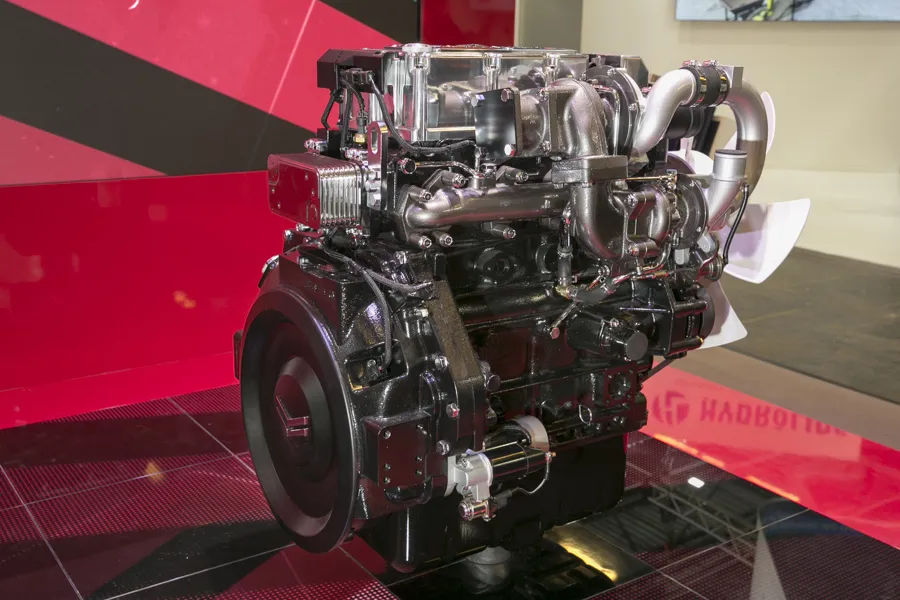

With power outputs ranging from 90-155kW, the 4.6litre 4TN107 can provide a power density of 33.7kW/litre, which the firm claims is the highest in its class, while it delivers 805Nm of torque.

The issue of power density is important and Guidici commented: “A bigger machine can be powered by a smaller engine.” He added that this means that for some installations, the 4.6litre unit will be able to take the place of 6litre engines.

The 3.8litre 4TN101 meanwhile offers power outputs of 55-105kW, with torque output of up to 550Nm. Both units are said to be compact in design, allowing them to be installed in existing machines with minimal design changes.

The units are also said to be durable and dependable. And Guidici said: “They offer reliability under every operating condition as well as low operating costs.”

Low emissions performance is delivered due to a two stage regeneration system, which the firm first introduced 10 years ago and has continued to fine tune to improve performance. Because this system is well-proven, Yanmar claims it is highly reliable and durable and is able to meet the latest emissions regulations.

Other proven technologies include the high pressure fuel injection system operating at 2,000bars, which Yanmar has developed completely in-house. This system helps to optimise combustion, providing the low fuel consumption and high torque and power outputs for each unit.