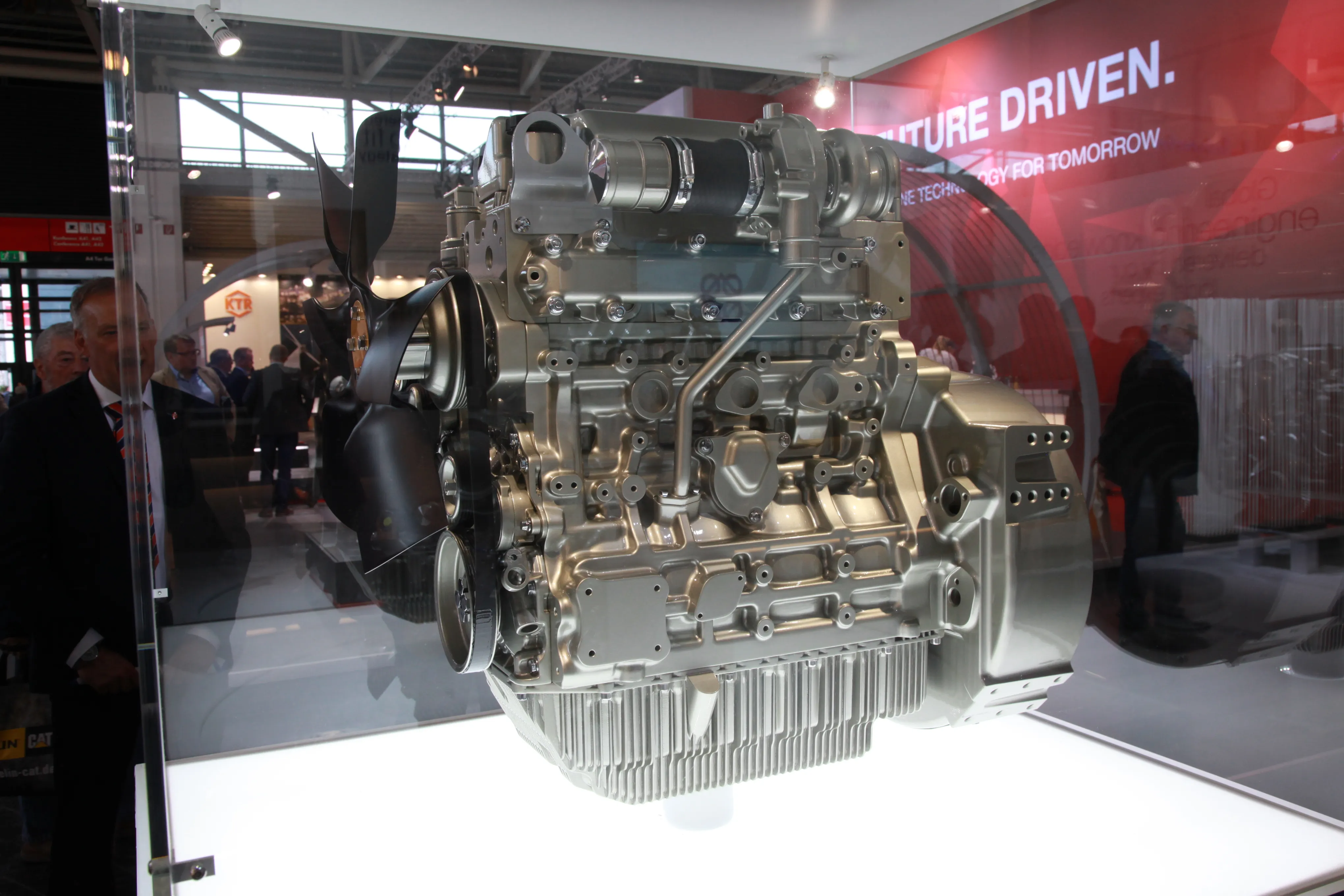

The 4TN101 is a 3.8litre displacement engine, which lines up in the 55-105kW power range with torque up to 550Nm, while the 4TN107 has a 4.6litre displacement with power ratings ranging from 90-155kW and torque exceeding 805Nm.

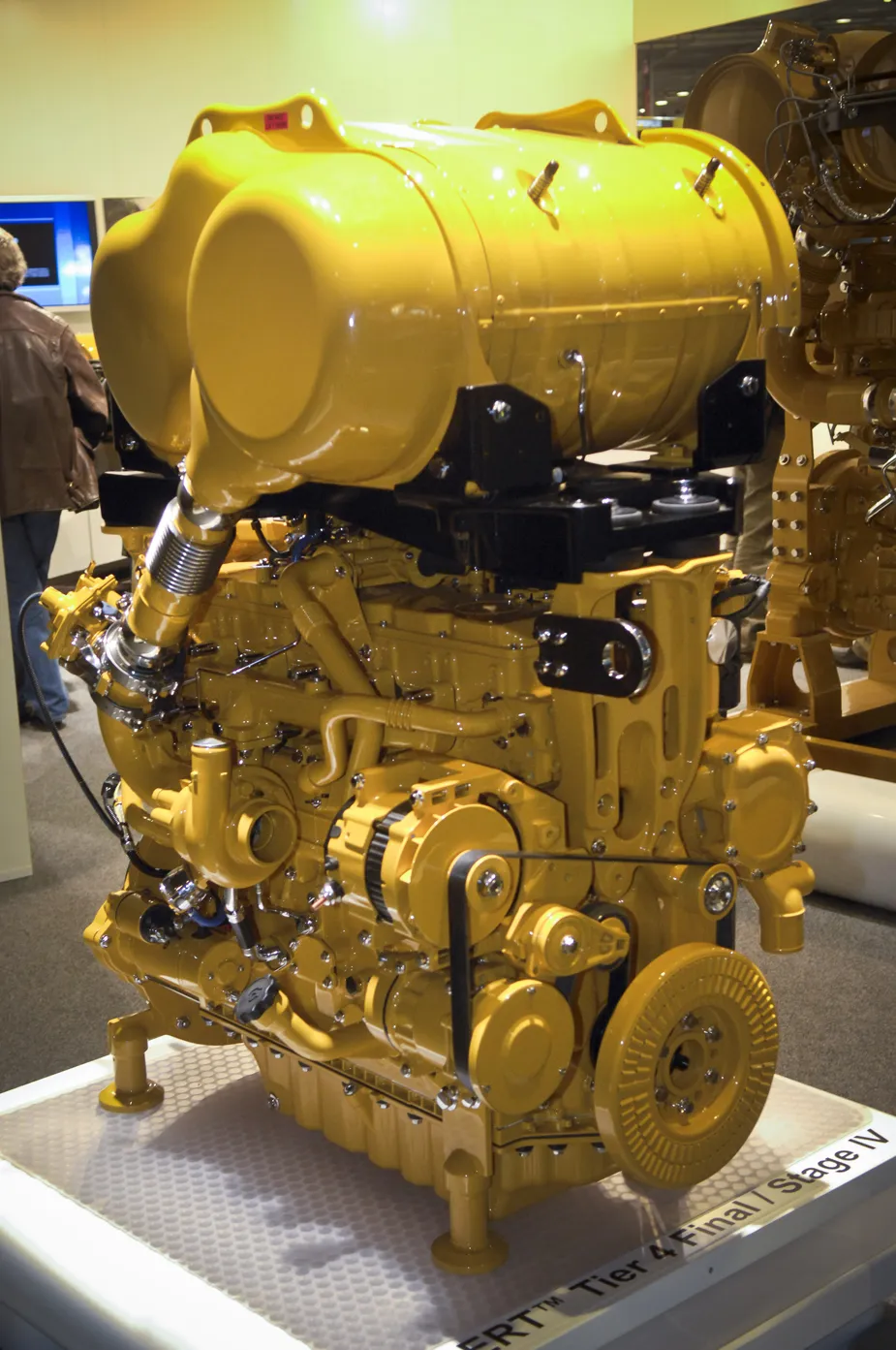

Both engines feature a Common Rail injection system, full authority electronics and after-cooled turbocharging (with a two-stage turbo on the 4TN107 upper ratings).

Both engine families will be EU Stage V-certified and, says Yanmar, share the same design target of reducing the total cost of ownership.

“Yanmar engineers’ efforts were focused on setting new fuel economy targets, leveraging its extensive know-how in combustion process optimisation gained through experience in diesel engines for industrial equipment and marine vessels,” says the company.

“Curbing lube oil consumption was another key design target, achieved thanks to a state-of-the-art high precision manufacturing process developed specifically for this purpose.”

The after-treatment system consists of EGR and separate DPF and SCR to safeguard durability and ensure exhaust gas cleaning performance. Smaller, separate after-treatment modules also allow for easier installation.

Production is planned to start from the beginning of 2019 onwards.