Wirtgen is offering two new milling machine models that maximise power, productivity and versatility. The W 210 XP is the latest model in Wirtgen’s large cold milling machine series and is designed to combine high power with ease of transport. The machine is driven by an emissions compliant diesel delivering 571kW, allowing a high power to weight ratio. Versatility is claimed as the machine has a 2m wide milling drum as standard but can also be fitted with milling drums that are 1.8m or 2.2m wide, if requir

February 28, 2018

Read time: 2 mins

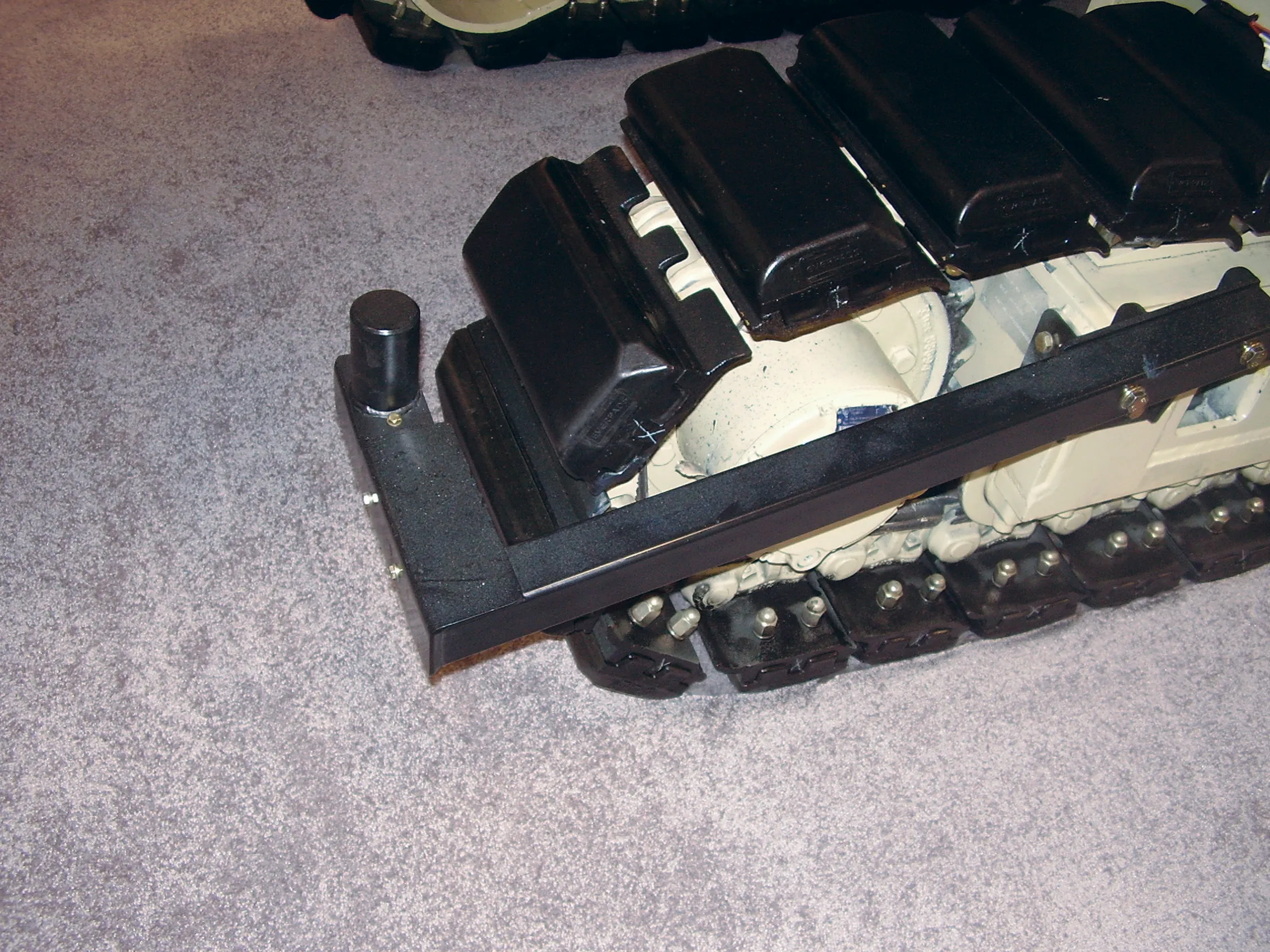

Also designed for versatility is the compact W 150 CFi milling machine. A key feature is the machine its new 1.8m milling drum unit, which offers a wider cut than most other machines in its weight class. Fitting such a wide drum on this class of machine allows contractors to carry out wider milling jobs in the more space-restricted sites seen on urban applications for example, increasing versatility and productivity.