The 4.5km TT circuit in Assen, Netherlands, is one of Europe’s iconic motorcycle race tracks built specifically for championship two-wheel races.

But years of hard and fast racing had created undulations 3-8 mm high along the start and finishing stretches. Drivers had to brake before turns. Even so, their machines would judder and threaten to be uncontrollable. It was therefore necessary to profile the raceway over an area of 3,000m² to restore the surface’s skid resistance.

Enter GMS Fahrbahnsanierun

October 16, 2015

Read time: 3 mins

The 4.5km TT circuit in Assen, Netherlands, is one of Europe’s iconic motorcycle race tracks built specifically for championship two-wheel races.

But years of hard and fast racing had created undulations 3-8 mm high along the start and finishing stretches. Drivers had to brake before turns. Even so, their machines would judder and threaten to be uncontrollable. It was therefore necessary to profile the raceway over an area of 3,000m² to restore the surface’s skid resistance.

Enter GMS Fahrbahnsanierungen which entrusted the pavement rehabilitation job to a2395 Wirtgen W 210i cold milling machine with cabin and FCS super-fine milling drum.

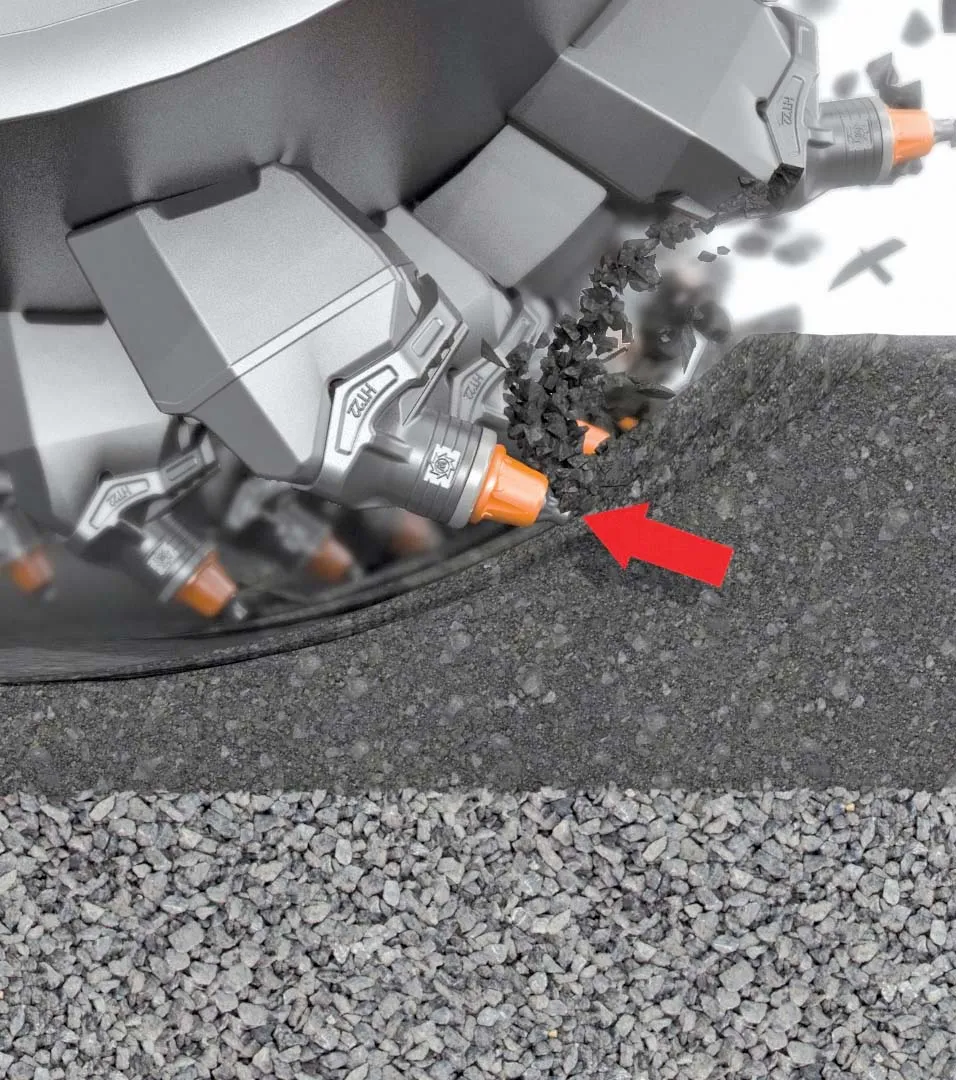

Super-fine milling removes surface deformations from the roadway to produce uniform, level surfaces. “We elected to use a Wirtgen W 210i cold milling machine with an FCS LA 6x2 super-fine milling drum,” explained Ernst Kugel, site manager at GMS. “Unlike a standard milling drum, it is fitted with 672 cutting tools rather than the usual 168."

Unlike standard milling drums, super-fine milling drums – also referred to as micro fine milling drums – have tool spacing of less than 6mm. They produce a very finely textured road surface with a maximum milling depth of 3cm.

The Wirtgen machine’s Flexible Cutter System allows it to switch between milling drums with different tool spacings and working widths according to different applications. Drums can be changed quickly in just a few swift moves. “It’s important for us to use the machines flexibly and thus cost-efficiently,” said GMS general manager Torsten Meyer.

The rehabilitation project on the TT circuit in Assen is a perfect example. GMS additionally used the Multiplex leveling system on this job, which is ideal for super-fine milling work, because it measures extended longitudinal irregularities by combining several sensors on one or both sides of the machine (e.g. cable, ultrasonic and cylinder sensors).

The current milling depth is calculated with utmost precision from the mean of the connected sensors. Longitudinal irregularities can, therefore, be effectively levelled out to achieve high-precision results. “The quality of the road surface is very good; we could not detect any residual unevenness,” said Kugel.

Also importantly, a Wirtgen W 210i with its Operator Comfort System offers an outstanding degree of comfort, convenience and user-friendly machine operation. One central element is the hydraulically moving and swiveling cabin. It shifts quickly and efficiently into a position that offers the machine operator optimum visibility at all times.

“The cabin’s high-quality interior, including camera transmission, precision joy-stick control and a powerful automatic climate control system provides the ideal working environment, regardless of weather conditions,” said machine operator Jürgen Dielefeld.

But years of hard and fast racing had created undulations 3-8 mm high along the start and finishing stretches. Drivers had to brake before turns. Even so, their machines would judder and threaten to be uncontrollable. It was therefore necessary to profile the raceway over an area of 3,000m² to restore the surface’s skid resistance.

Enter GMS Fahrbahnsanierungen which entrusted the pavement rehabilitation job to a

Super-fine milling removes surface deformations from the roadway to produce uniform, level surfaces. “We elected to use a Wirtgen W 210i cold milling machine with an FCS LA 6x2 super-fine milling drum,” explained Ernst Kugel, site manager at GMS. “Unlike a standard milling drum, it is fitted with 672 cutting tools rather than the usual 168."

Unlike standard milling drums, super-fine milling drums – also referred to as micro fine milling drums – have tool spacing of less than 6mm. They produce a very finely textured road surface with a maximum milling depth of 3cm.

The Wirtgen machine’s Flexible Cutter System allows it to switch between milling drums with different tool spacings and working widths according to different applications. Drums can be changed quickly in just a few swift moves. “It’s important for us to use the machines flexibly and thus cost-efficiently,” said GMS general manager Torsten Meyer.

The rehabilitation project on the TT circuit in Assen is a perfect example. GMS additionally used the Multiplex leveling system on this job, which is ideal for super-fine milling work, because it measures extended longitudinal irregularities by combining several sensors on one or both sides of the machine (e.g. cable, ultrasonic and cylinder sensors).

The current milling depth is calculated with utmost precision from the mean of the connected sensors. Longitudinal irregularities can, therefore, be effectively levelled out to achieve high-precision results. “The quality of the road surface is very good; we could not detect any residual unevenness,” said Kugel.

Also importantly, a Wirtgen W 210i with its Operator Comfort System offers an outstanding degree of comfort, convenience and user-friendly machine operation. One central element is the hydraulically moving and swiveling cabin. It shifts quickly and efficiently into a position that offers the machine operator optimum visibility at all times.

“The cabin’s high-quality interior, including camera transmission, precision joy-stick control and a powerful automatic climate control system provides the ideal working environment, regardless of weather conditions,” said machine operator Jürgen Dielefeld.