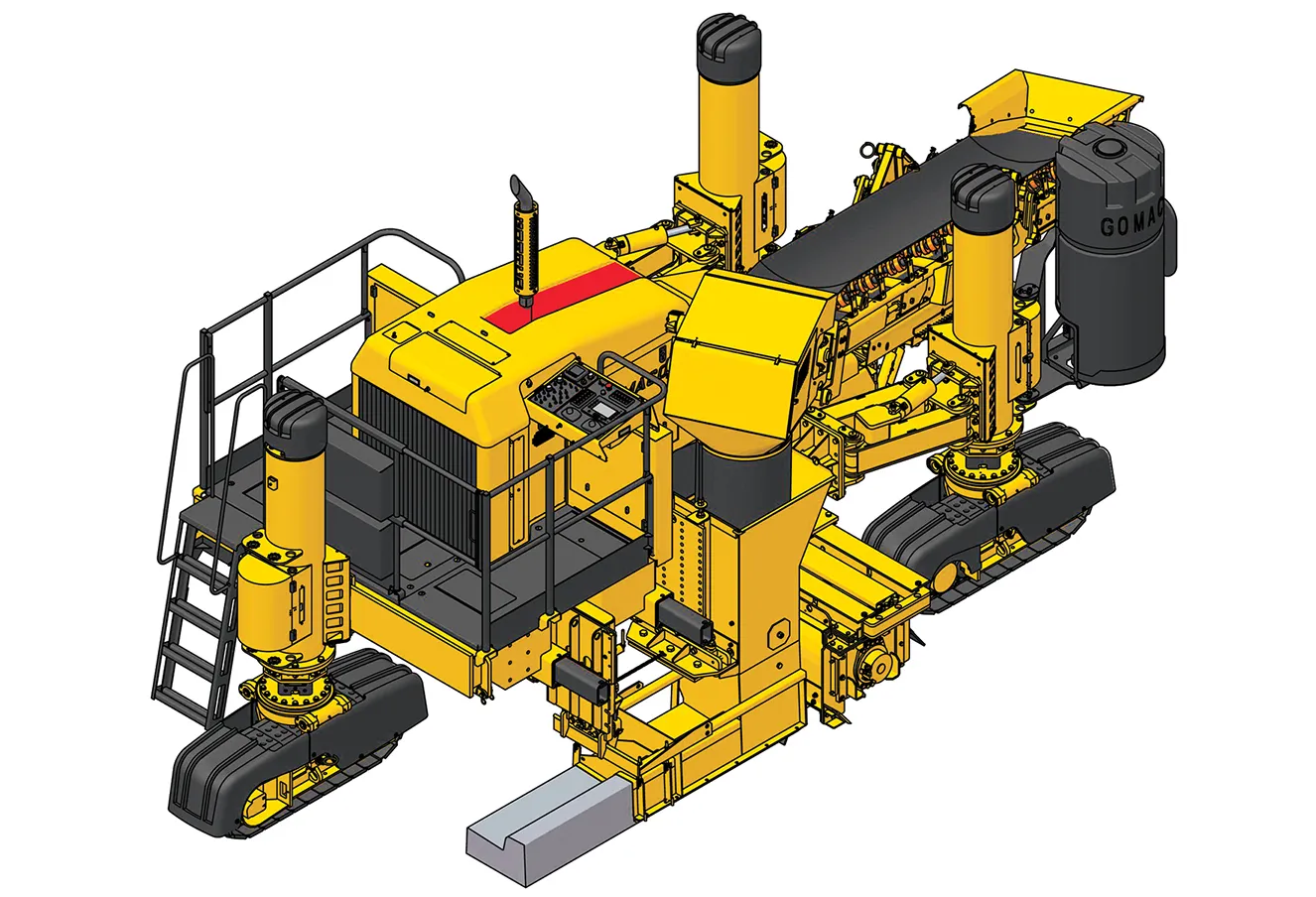

Wirtgen is expanding its range of slipform pavers with the new SP 60 series and SP 90 series models. The SP 60 models are smaller units designed to be used in a range of applications while the larger SP 90 series suit duties such as highway or runway construction.

The SP 60 models include the SP 61i, SP 62i and SP 64i and will replace the earlier SP 500 design. Power comes from a diesel delivering 180kW in Tier 4 Final/Stage IV and 155kW in Tier 3/Stage IIIA emissions ratings. The SP 64i can feature four

January 6, 2017

Read time: 3 mins

The SP 60 models include the SP 61i, SP 62i and SP 64i and will replace the earlier SP 500 design. Power comes from a diesel delivering 180kW in Tier 4 Final/Stage IV and 155kW in Tier 3/Stage IIIA emissions ratings. The SP 64i can feature four hydraulically moved swivel arms, allowing it to switch from transport mode to working mode more rapidly than the SP 500. And using the firm’s optional Paving Plus package, the swivel arms can allow the machine to go around obstacles during paving work. The SP 60 series models are designed for inset and offset paving to thicknesses of 350mm, offering maximum widths of up to 6m when using a dowel bar inserter (DBI) and 7.5m without.

The machines have a new operating concept said to optimise control and deliver better and more consistent paving quality. The machines have a central control system and four additional local control systems as standard. Among other things, remote controls can be connected to each of the crawler tracks to simplify and speed up set-up. Standardised interfaces and a BUS system ensure a high degree of flexibility when it comes to optional upgrading or conversion of the machine. The addition of further machine components to cater to complex, customer-specific job requirements is a simple process, enabling the SP 60 series to handle a wide variety of applications. Customers can choose different slipform systems for inset paving. In principle, the slipforms can also be used for the larger SP 90 series. Offset slipforms can also be used; these are supplied with a variety of typical offset options, such as trimmers, different conveyor belts or augers to feed the offset slipform.

For offset duties, the three- or four-crawler version of the SP 61i can slipform large or small concrete profiles to the left or right of the machine. A wide array of molds are offered to suit different applications.

The new large slipform pavers include the SP 92i and SP 94i models, which are modular in design for versatility. The SP 90 series includes the modular SP 94i inset version with four steered and pivotable crawler tracks. This can produce concrete pavements 3.5-9.5m wide and up to 450mm. Options include the DBI, tie bar and side tie bar inserter, as well as different slipform systems tailored to the regional requirements for inset applications worldwide, allow the SP 94i to be configured for a whole range of applications. Like the SP 92i, it stands out through the high accuracy of its paving, its intuitive operation and highly convenient operation.

Both the SP 90 and the SP 60 series are said to be cost-efficient and productive, as well as being versatile. Other features include the Eco Mode engine management system, which adapts engine output to the requirements of the job, and the 3D interface Easy Connect, ensuring more precise concrete paving to high quality standards.

All videos