The vibratory plate AP1850e is the only battery-powered plate on the market, according to Wacker Neuson. With a running time of up to one hour, it can be used for the best part of a workday on almost any building site. Electric drives are becoming ever more important for rental fleets and on projects such as interior space restructuring or tunnel construction.

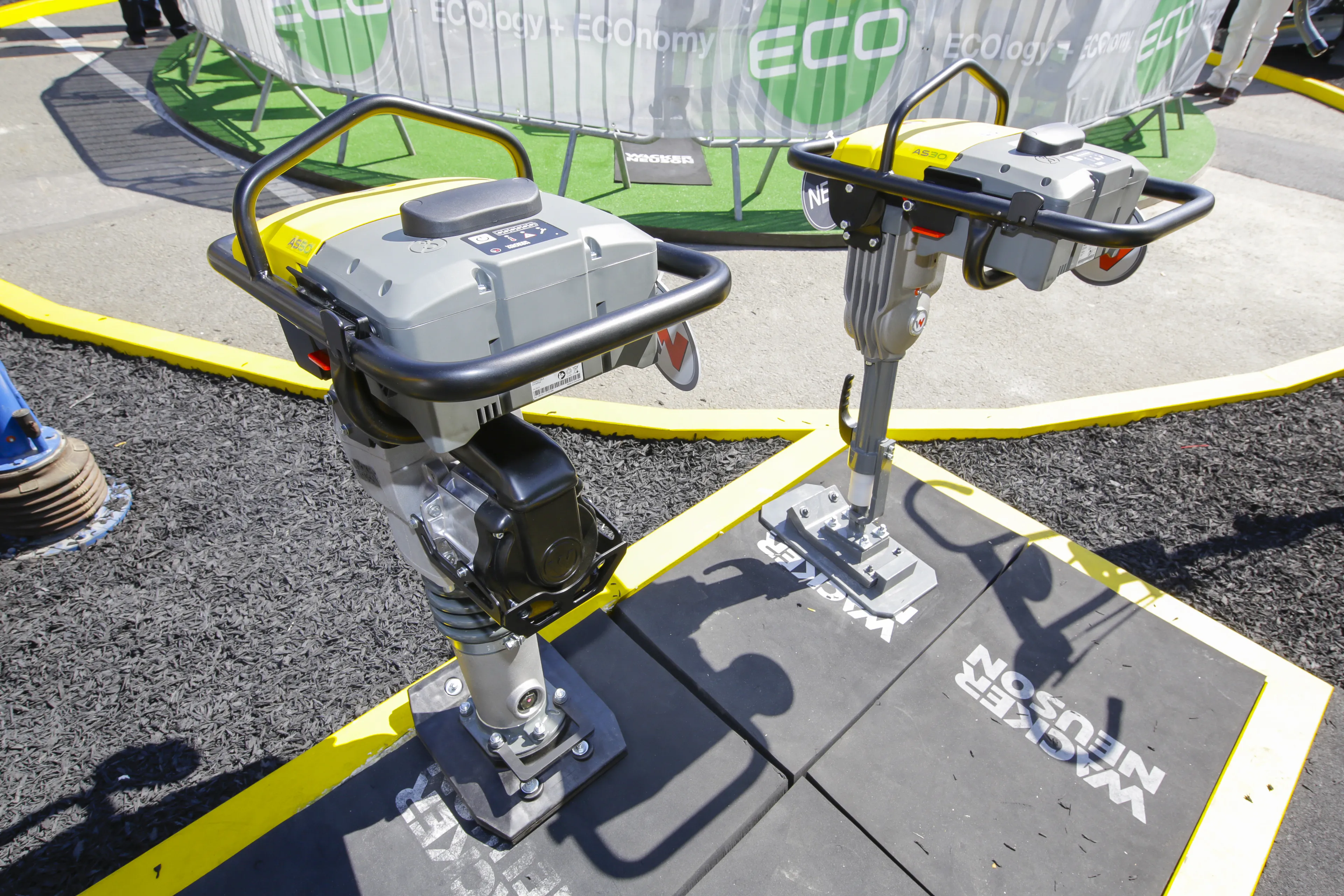

The modular design means that the AP1850e’s battery and the charger are those used Wacker Neuson's battery rammer. This increases flexibility because customers can use the battery in one of the devices while charging the other.

The vibratory plate is particularly suitable for compaction of both granular and asphalt surfaces, says the company.

Wacker Neuson says the obvious advantage of electric drive is the maintenance-free aspect. However, the design of a battery that can be used in several machines adds value for customers. The concept of a modular battery pack will be used to progressively offer customers battery-powered machines for many uses.

Alongside the new plate, the company’s zero-emission range includes two battery rammer models, the dual power excavator, an electric-operated track dumper and an electric wheel loader. All will be at the forefront of the Wacker Neuson Group stand at Intermat.