Volvo Construction Equipment’s new 55-tonne capacity Volvo A60H meets growing customer demand for articulated haulers with larger capacities.

The articulated hauler concept was originally launched by Volvo in 1966 and celebrates its 50th birthday this year.

The Volvo A60H’s higher payload – a 40% increase on Volvo’s A40 –lowers the cost-per-tonne for hauliers. It also offers an alternative to rigid dump trucks and construction trucks operating on soft, uneven or steep roads, allowing a similar amount

March 16, 2016

Read time: 2 mins

The articulated hauler concept was originally launched by Volvo in 1966 and celebrates its 50th birthday this year.

The Volvo A60H’s higher payload – a 40% increase on Volvo’s A40 –lowers the cost-per-tonne for hauliers. It also offers an alternative to rigid dump trucks and construction trucks operating on soft, uneven or steep roads, allowing a similar amount of material to be hauled in a shorter cycle time.

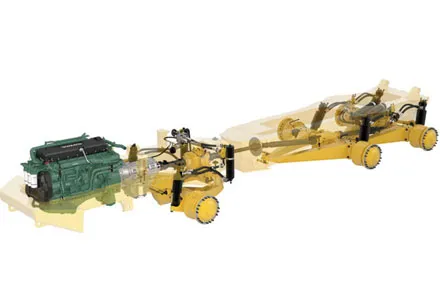

Good stability, comfort and high hauling speeds are ensured by the matched drivetrain, automatic drive combinations (including 100% differential locks), all-terrain bogie, hydro-mechanical steering and active suspension.

Volvo builds on the high capacity and hauling speeds of the A60H with intelligent monitoring systems, such as MATRIS, CareTrack. The Volvo On Board Weighing System further optimises production and minimises operational costs. The Volvo Care Cab has a centrally-positioned seat, superior steering, excellent suspension, low noise levels, climate control and ample space and visibility.

Volvo articulated haulers have a high degree of uptime thanks to heavy-duty front and rear frames, hitch and wet disc brakes. Servicing and routine maintenance checks are easier thanks to quick access from a front grill that swings down, opening up a service platform with anti-slip steps and an electric hood that opens to 90°, allowing full and safe access to the engine compartment. In addition to long service intervals and minimal maintenance requirements, Volvo’s popular Customer Service Agreements help customers stay in control of costs.