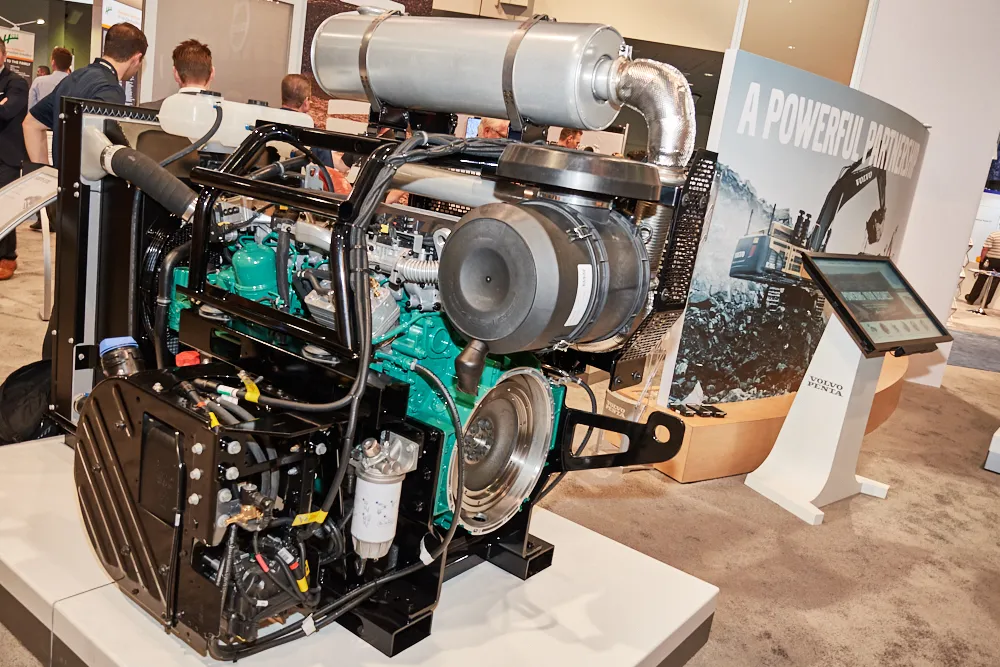

For Stage V, the engine platform gets a fixed geometry turbo, common-rail fuel injection system and uncooled exhaust gas recirculation. An electrical exhaust pressure governor and inlet throttle enable the system to function without the need to inject fuel into the exhaust stream to raise the temperature.

With this approach, Volvo Penta said the exhaust gas has an optimal temperature when it passes through the exhaust after treatment system. It added that low heat rejection from the entire system means less cooling is required.

Power remains unchanged, and extends from 105 to 565kW (143-770 hp) to suit industrial and off-road applications. The firm is ensuring compatibility with earlier emissions legislations by using the same hardware layout and re-using the electrical architecture to deliver consistency across different emission stages.