Electrification of powertrains is now being seen in many sectors including cars, trucks and construction machines. There has been a spate of construction machine and industrial engine launches featuring either hybrid powertrains or all-electric systems. Volvo Penta’s president and CEO, Björn Ingemanson, commented: “It’s happening very fast now.”

Volvo’s bus business has had long experience of hybrid technologies, and more recently with battery-powered units. And this in-house experience is being shared with other divisions. Senior vice president Johan Carlsson commented: “We have a strong foothold in the group with trucks, buses and construction machines. We have always been at the forefront of driveline developments.”

Compressed gas offers one clean tailpipe option and Carlsson said: “Across the group we have different types of solutions.” He added that all the firm’s diesel engines can be run on HVO, a second generation biofuel, while the company’s marine engines offer the alternative of methanol as a fuel.

Looking ahead to potential future replacements for diesel as a fuel, Carlsson commented: “Whatever the legislators decide, we have solutions.”

But Ingemanson added: “The infrastructure needs to be there.”

Another fuel source proposed in the past is hydrogen, either for direct combustion or for fuel cells. Carlsson confirmed: “We have been looking at fuel cells for decades. It’s one of the solutions for auxiliary power. There are a number of companies working on the technology.”

In the nearer term, Carlsson feels hybrid systems offer great potential. “What’s interesting with hybrids is that we can further increase application performance. You can set them to deliver increased torque at lower revs for instance.”

Both Ingemanson and Carlsson believe that offering a range of power solutions points the way ahead. The latter added: “Some markets suit all-electric operation, where machines are in a controlled environment.”

He said that with regard to electric buses, there are now established practices on recharging, with some methodology that could be applied to certain sectors of the off-highway machine sector. For equipment used in smaller quarries or tunnelling or mining operations, for example, the potential for electric machines is stronger, as charging stations could be located on hand. However for other machines, other power options may be more practical.

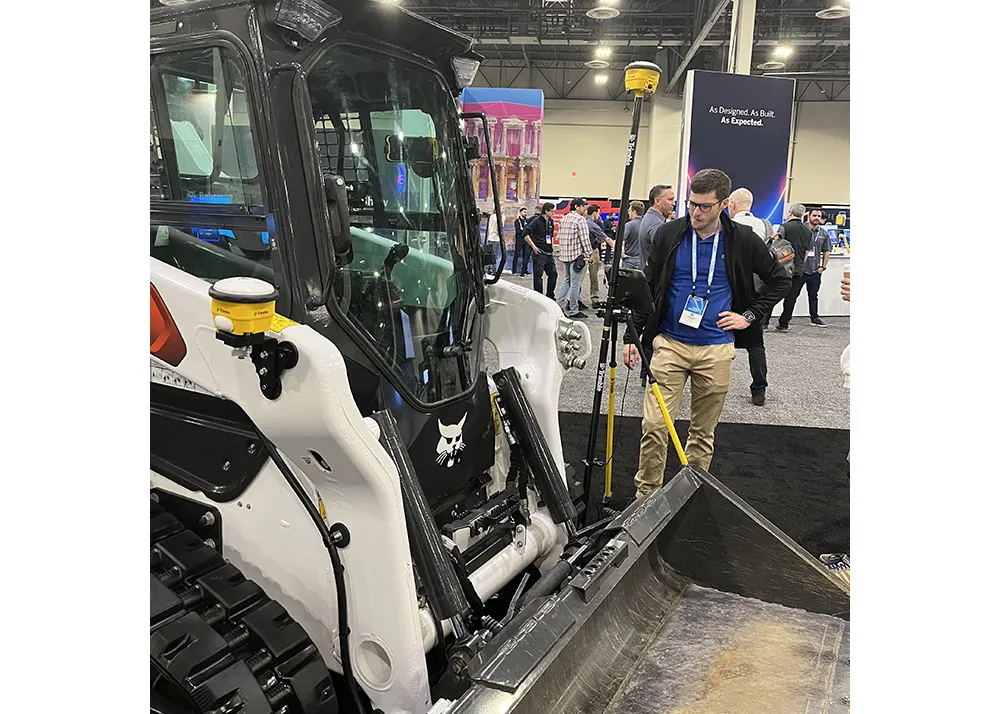

The use and operation of smaller units aimed at the rental sector is more predictable and therefore electric power may also be more suitable. Rental firms could also benefit from the lower running costs of electric units, with no need for periodic engine maintenance tasks.

Carlsson said that battery technology continues to improve, while the units are also becoming cheaper. However he added that high performance capacitors also offer a strong potential for use with electric equipment, particularly when high discharge rates are required.

But looking ahead, the firm believes that diesel engines still have a long future, especially as the latest generation of off-highway units do offer far lower emissions levels. And Ingemanson added: “Diesel will be around for some time.”