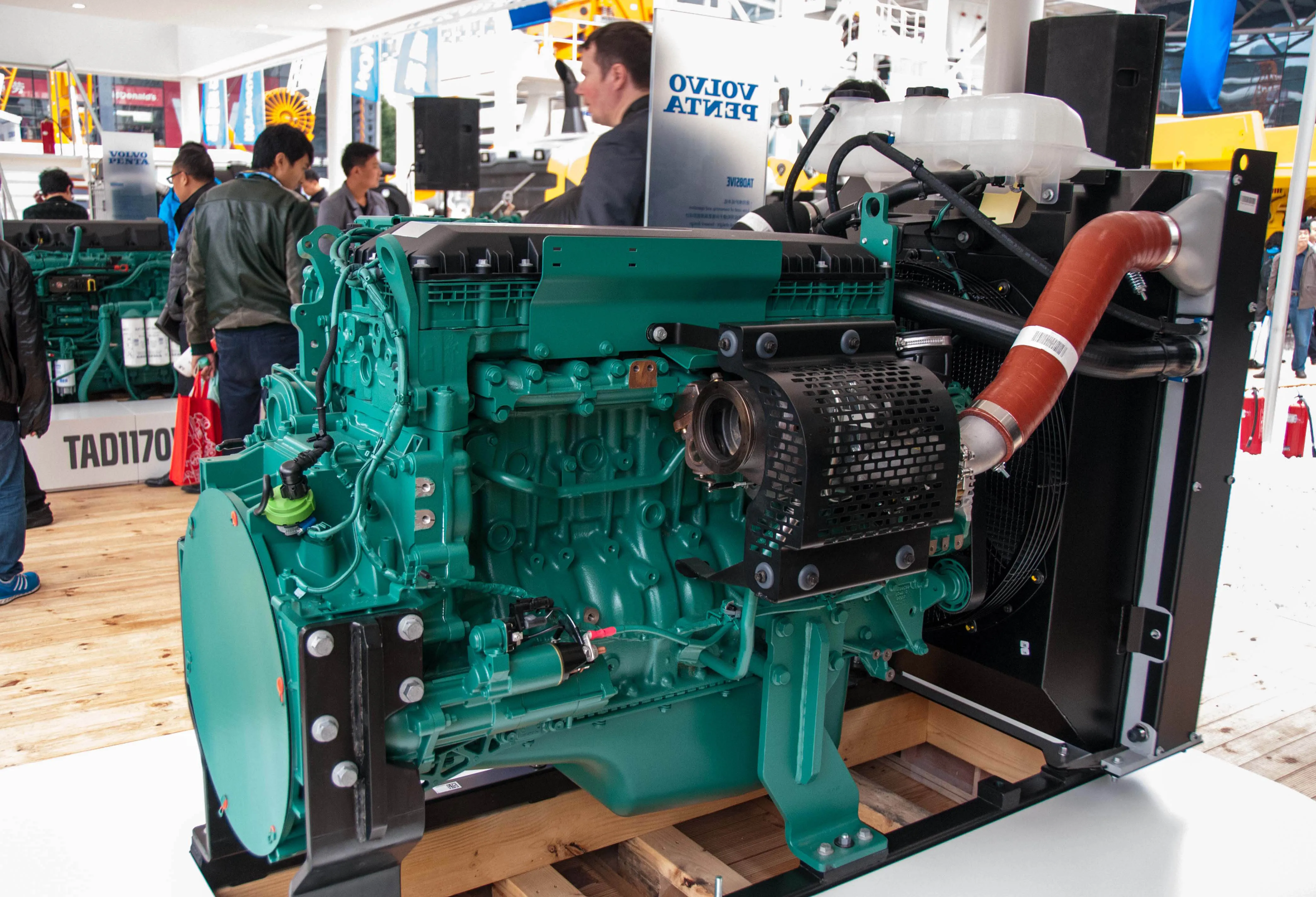

Volvo Penta displayed a number of new engines for China and world markets at bauma 2014 in Shanghai, China. Throughout the year Volvo Penta has released new engines for a complete line of Tier 2 and Tier 3 engines. These share a common design with Tier 4 engines which means OEM manufacturers can fit an engine suitable for the customer and the applicable emissions standards without having to do a major redesign to accommodate a different engine.

November 27, 2014

Read time: 2 mins

“Our new common engine platform allows them to fit a Stage II, Stage IIIA/China III or Stage IV engine to the same machine without a hassle,” says David Hanngren, manager of industrial product planning at Volvo Penta. The stage II and IIIA engines use an advanced clean-burning fuel injection system which means that they don't need an after-treatment system to lower emissions levels.

The Volvo Penta range consists of a complete line of 5, 8, 11, 13 and 16litre engines for off-road use. Volvo Penta displayed the new TAD1350VE which is certified to China III standard. Volvo Penta will likely to be among the first engine manufacturers to achieve China III certification for its range. The 13litre in-line 6 cylinder unit delivers 256kW and torque of 1780Nm while weighing in at 1,335kg. Also on display was the TAD815VE an EU Stage IIIA compliant unit. This 8 litre class straight six engine delivers 185kW of power and 1160Nm of torque.

In addition the TAD873VE was displayed which is Stage 4 standard with selective catalytic reduction (SCR) technology. Power from the six cylinder 8 litre engine is 235kW and it has torque of 1310Nm.