Volvo Penta will show two newly-redesigned 5litre and 8litre engines and a complete range of common-platform units spanning all emission levels.

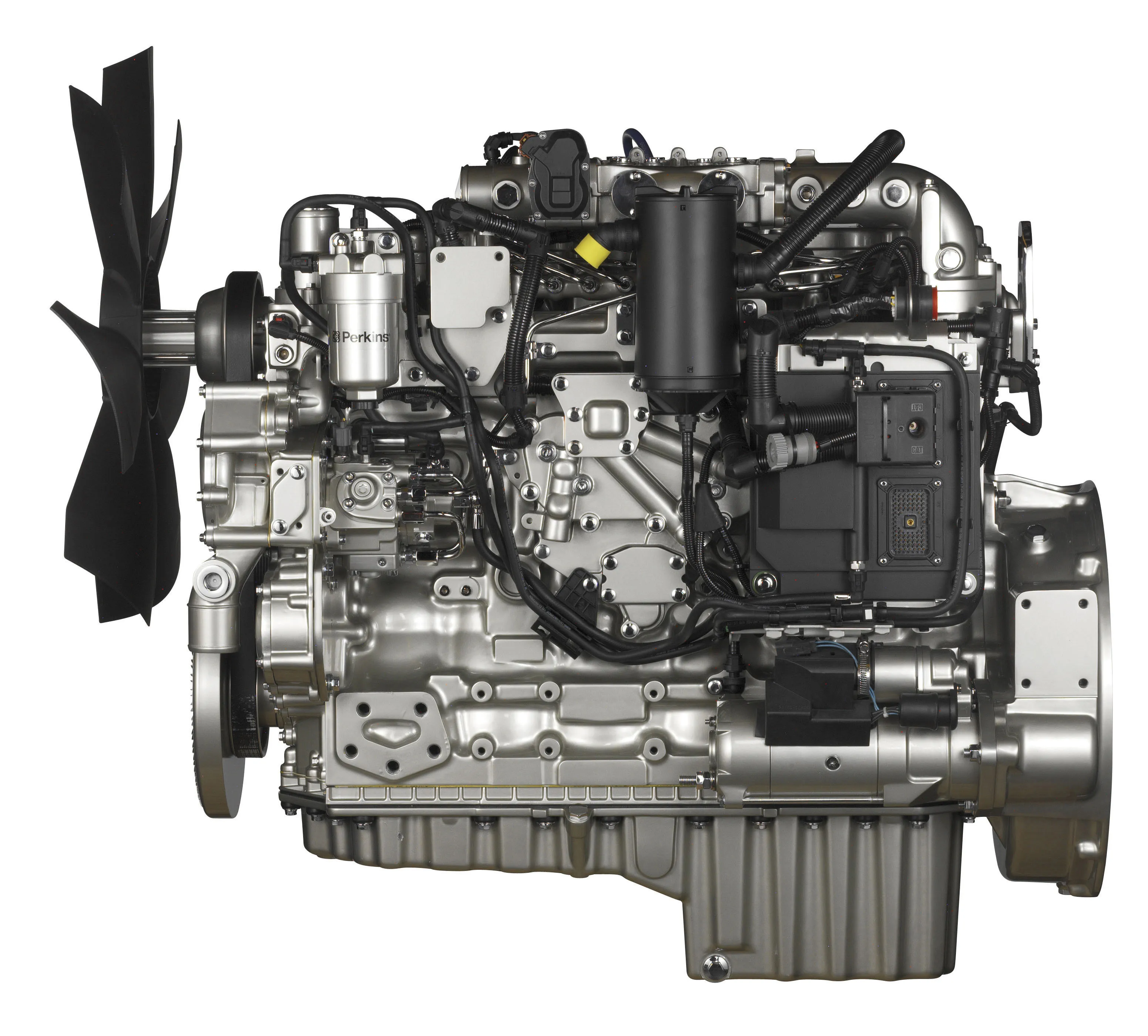

The company’s Stage IV/Tier 4 Final D11 engine will be seen with the new Stage IV/Tier 4 Final-compliant 5litre and 8litre engines.

Developed in coordination with the Volvo Group, the D5 and D8 engines feature a newly-designed platform, and are also available to meet Stage II/Tier 2, Stage IIIA/Tier 3 equivalent and Tier 4 Final/Stage IV emissions standards. This

January 6, 2017

Read time: 2 mins

The company’s Stage IV/Tier 4 Final D11 engine will be seen with the new Stage IV/Tier 4 Final-compliant 5litre and 8litre engines.

Developed in coordination with the Volvo Group, the D5 and D8 engines feature a newly-designed platform, and are also available to meet Stage II/Tier 2, Stage IIIA/Tier 3 equivalent and Tier 4 Final/Stage IV emissions standards. This means where a manufacturer exports its products, Volvo Penta has an engine to match the market’s emission regulations.

All Volvo Penta’s engines, regardless of emission stage, share a common footprint, with components such as the turbocharger located in the same place on all models.

The range also shares a common electronics platform that allows them to communicate using the same protocol, regardless of emissions level.

The company says that displacement has also been increased, compared to previous versions, offering improved engine block stiffness, as well as higher torque at low speed, but “despite a larger displacement, fuel consumption is reduced by as much as 2.5%.”

Volvo Penta will also show off its Tier 4 Final/Stage IV after-treatment system, selective catalytic reduction (SCR), for the D5 and D8. It says it is a simple and straightforward way of lowering nitrogen oxide (NOx) levels. With SCR technology, AdBlue is injected into the exhaust line and reacts with NOx in the catalytic converter to turn the harmful compound into nitrogen and water.

“The SCR-only solution requires fewer parts and less maintenance than other kinds of after-treatment systems,” says Volvo Penta.