Volvo Penta has highlighted its battery-electric platform for construction, emphasising its battery energy storage (BESS) subsystem.

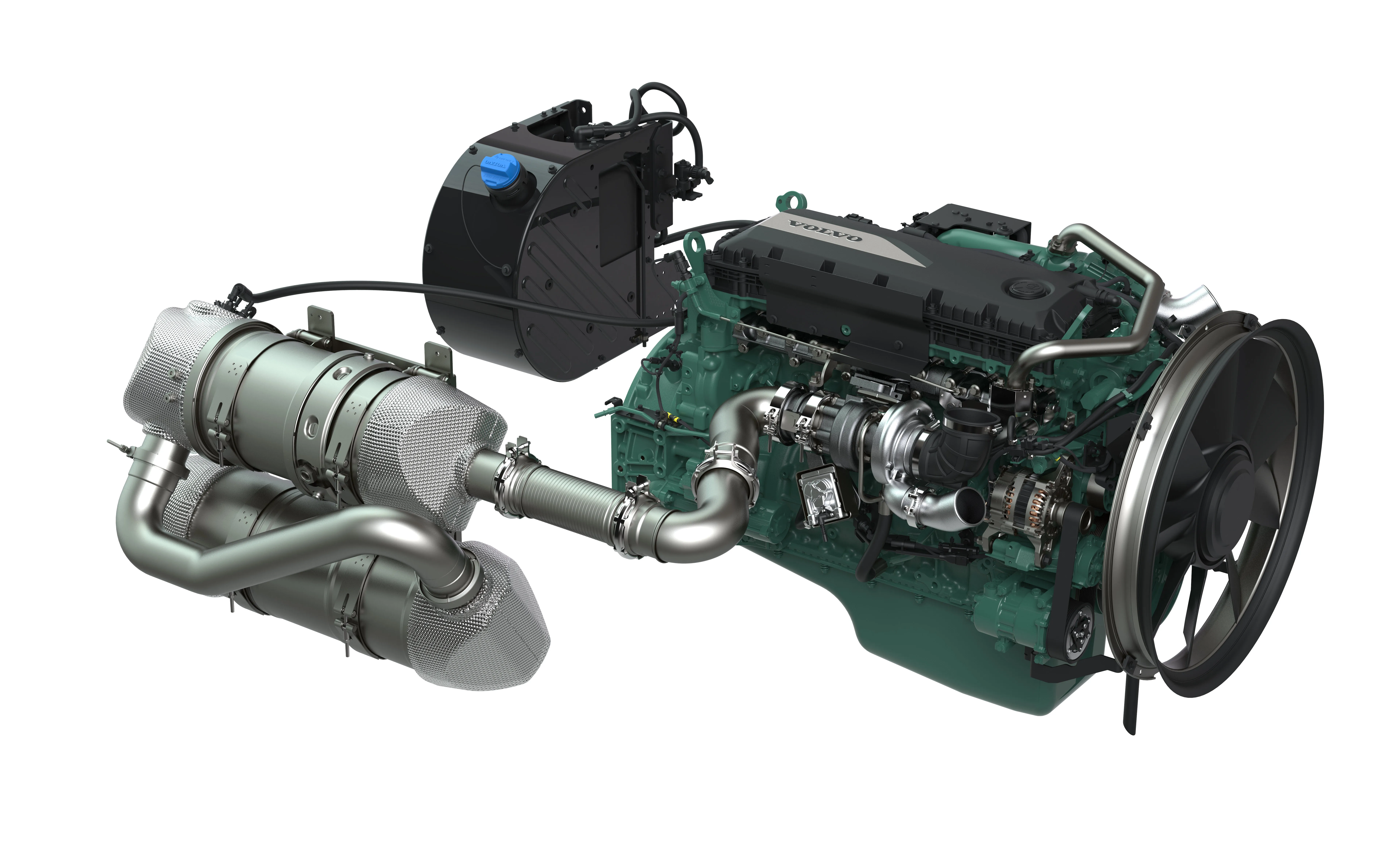

The engine manufacturer says it delivers dependable power through its core pillars: proven combustion engines, purpose-built electric drivelines, and integrated battery energy storage subsystems.

Volvo Penta’s scalable and modular BESS subsystem enables OEMs and system integrators to seamlessly integrate and deploy electric power to meet energy needs in construction.

The same high-performance, energy-dense battery technology used in Volvo Penta’s electromobility drivelines now powers its BESS subsystem - designed for reliable performance, durability, and resistance to dust and corrosion in tough environments. Volvo Penta’s BESS subsystem enables system integrators and BESS manufacturers to create tailored solutions for everything from mobile, temporary power applications to permanent infrastructure at electric sites. This provides a flexible, robust and scalable foundation that customers can seamlessly adapt to their business needs and meet growing energy demands while maintaining productivity and uptime.

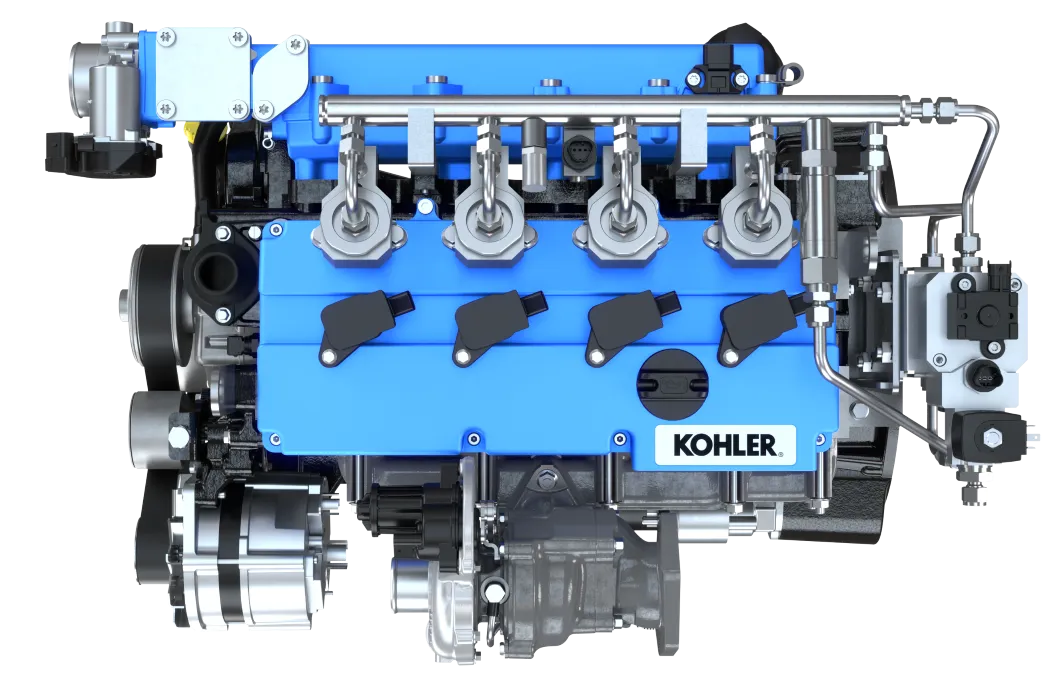

As the energy transition evolves, high-efficiency combustion engines remain crucial for off-highway and power generation applications. Volvo Penta says it is committed to the industry's path to net zero, supporting renewable fuels like HVO as well as advancing hydrogen dual-fuel technology (such as the one on its Stage V D8 platform). These innovations align with stringent emissions regulations while ensuring reliability and performance, aimed at contributing to a more sustainable future for off-highway and stationary power applications.