Offering claimed best-in-class efficiency, the EC220E follows the successful D-Series model with reduced emissions and fuel consumption, as well as enhanced power and productivity.

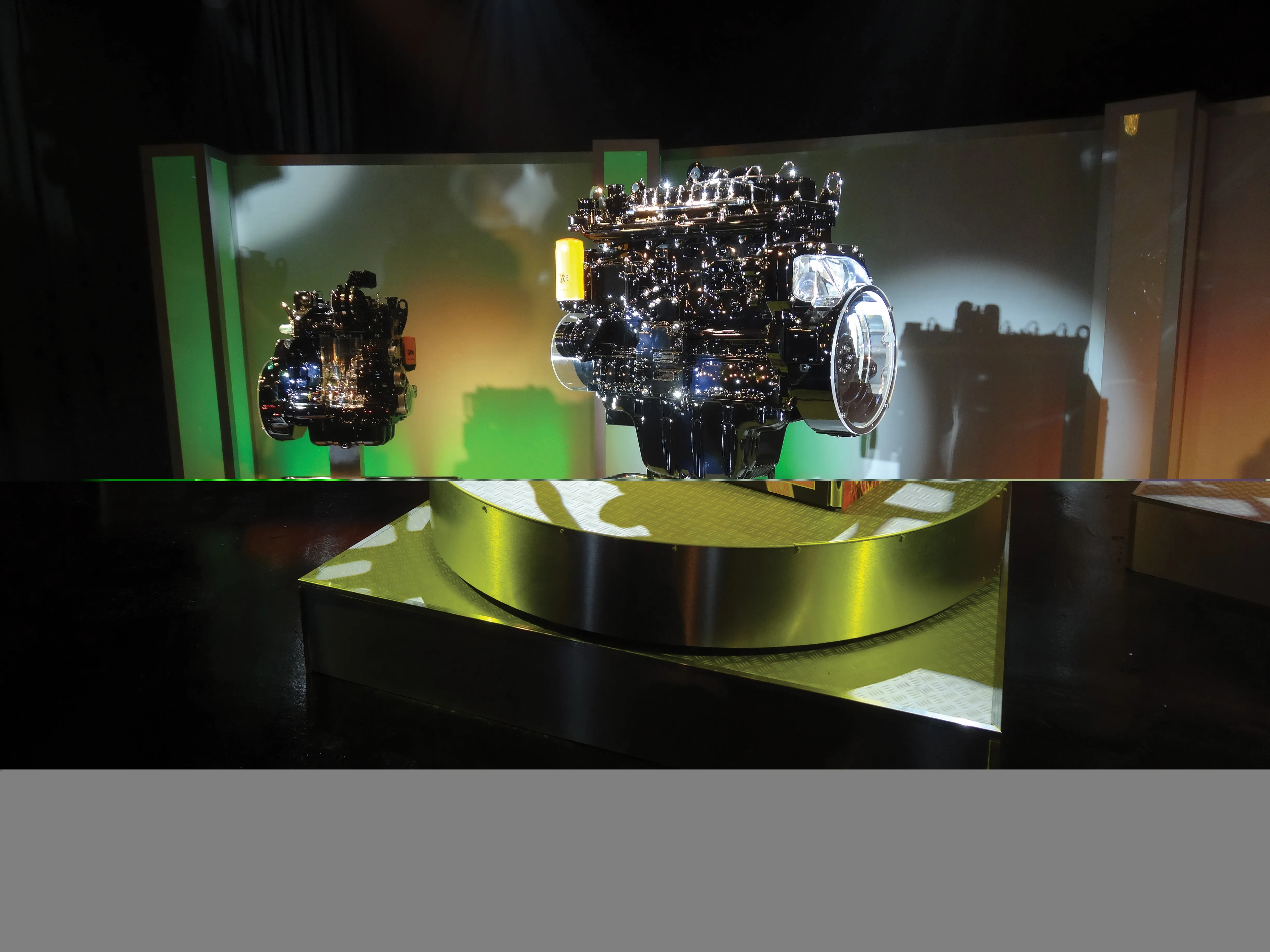

The latest 22tonne crawler excavator is fitted with a top-range Tier 4 Final/Stage IV Volvo D6 engine and has a fully optimised hydraulics system and ECO mode to deliver the precise amount of power required to complete the task in hand, while an auto engine shutdown feature helps further reduce fuel consumption and emissions, by automatically switching off after the excavator has been inactive for a pre-set amount of time.

The increased pump input power on the EC220E is said by Volvo CE to enable highly responsive operation for greater productivity and cycle times – and with the boom float function, the pump power normally used for boom lowering can be saved or used for other functions, also reducing cycle times.

The new Volvo EC220E is said to place comfort at the heart of its design. All machine interfaces – including the joysticks, keypad and easy-to-read LCD monitor – are ergonomically designed and can be fine-tuned according to operator preference.

For the safety of both the operator and site staff, the new crawler excavator model now also includes an optional side view camera in addition to the rear view camera to cover the visual blind spot. Both views are displayed on the colour monitor.

The EC220E is engineered to continue working hard over a long service life. Silicone caulking is used to prevent rust, while waterproof harnesses and connections come as standard. The design also incorporates heavy-duty door hinges and bolt-on protection for the framework lights.

The X-shape lower frame enables even weight distribution for increased stability and durability and helps prevent damage from rock and debris. The heavy-duty undercarriage likewise creates excellent tractive force in demanding terrain. The robust design of the boom and arm includes internal plates positioned to support pressure points during a wide range of applications.

The EC220E excavator is said to make daily service checks quick and easy to carry out thanks to grouped filters that are easily accessible from ground level. The single layer cooling system is also easily accessed from ground level by simply opening the side door.