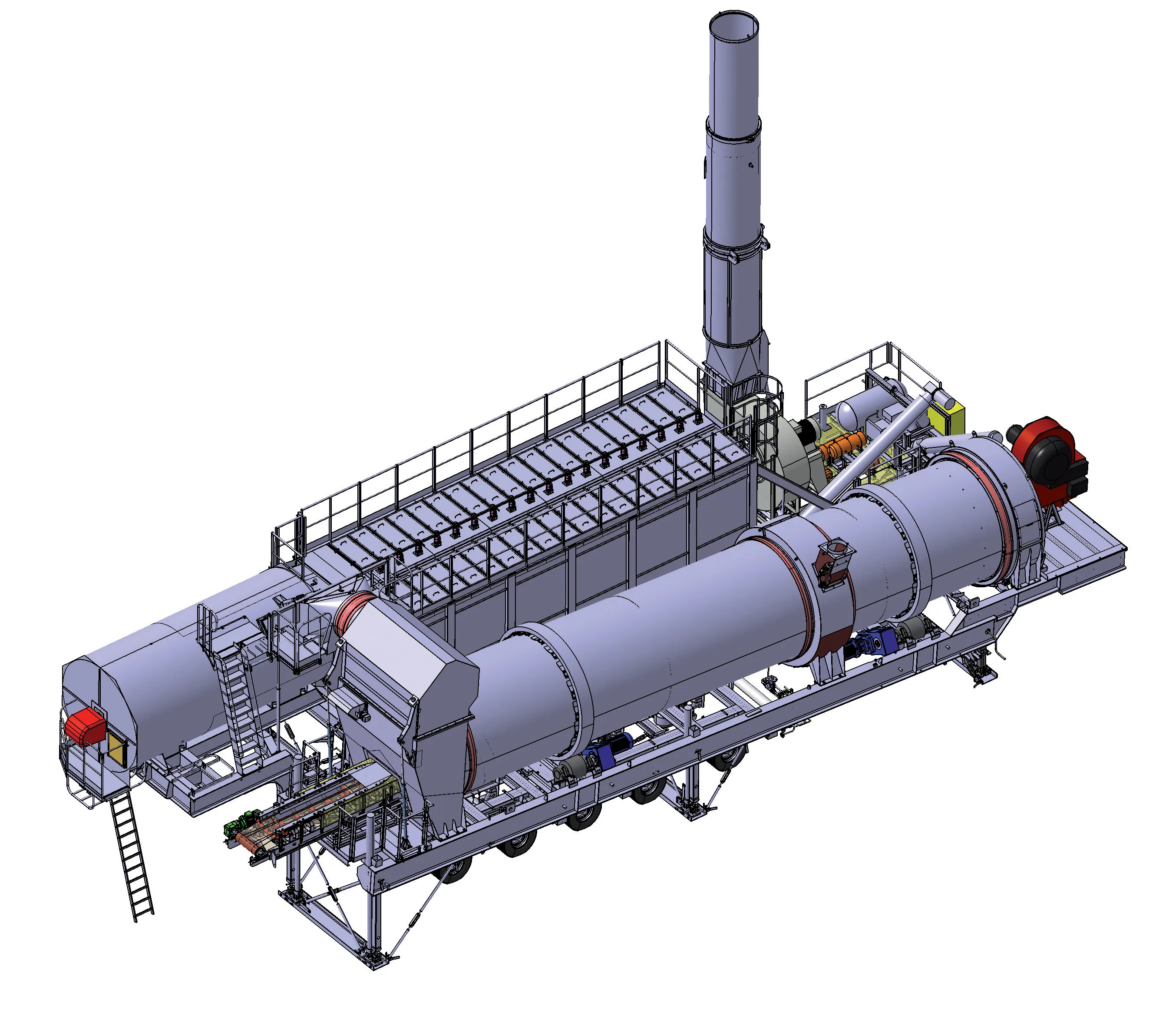

At the centre of the plant is the new BBX 1250 screening and mixer unit, which can be transported on one truck.

The entire plant can be transported in five truck loads meanwhile. The BBX 1250 section comprises a four deck screen capable of separating 90tonnes of aggregate/hour and a 1.25tonne capacity mixer. With this set up the plant can deliver an output of up to 100tones/hour and can be quickly taken apart and moved for use on another site. A 40tonne capacity crane is required for set up purposes.

The plant comes supplied with the necessary aggregate fractions in its four cold feed hoppers. These feature a convenient loading width of 3.6m. The drying drum is mounted on the same chassis to ensure quick and efficient drying of the aggregate. The plant’s four deck screen separates material into the four comportments of the hot aggregate bin unit, which can store up to 20tonnes.

The digital real-time weighing and dosing technology of this plant ensures that the mixer is supplied with the right components as required for the specified formula. The bitumen supply is also mounted on a chassis. In addition to the 40m³ tank, the filling and dosing units are also integrated so as to ensure optimum access while saving space.

The innovative dust collection system includes a filter and exhauster as well as a 15m³ silo for reclaimed filler and a 25m³ silo for imported filler.

This makes the BBM 1250 ideal for mobile use throughout the world. The components' user-friendly design and the intuitive control system BLS 3000 make this plant a reliable partner in the production of high-quality asphalt.