High power output, performance and reliability are claimed by

The concrete mixer has a yield of 3.5m3 and a double mixing blade. The mixing and jet speeds are maintained, regardless of engine rpm. Its 600litre capacity loader can be controlled by the Joymix system for loading sand or gravel directly into the barrel. In addition, the versatility of the carrier unit allows the machine to cope with slopes of up to 30%, even when the machine is carrying a full load.

The novel Concrete-Mate system is said to allow the mix to be weighed directly inside the barrel. Conventional systems that use hydraulic sensing on the blade, however the Carmix unit is said to offer more accurate data on the quality of the concrete. This device is said to deliver a high quality product ready to be used on any worksite, at any latitude, quickly. The system also reduces mechanical stress due to the efficient mixing method, decreasing the need for additives. The quality is confirmed by the Legal for Trade certificate, an accreditation that allows the machine to conform to strict requirements for Europe, Australia, Canada and Russia.

Digital technologies are said to help deliver consistent quality and quantity.

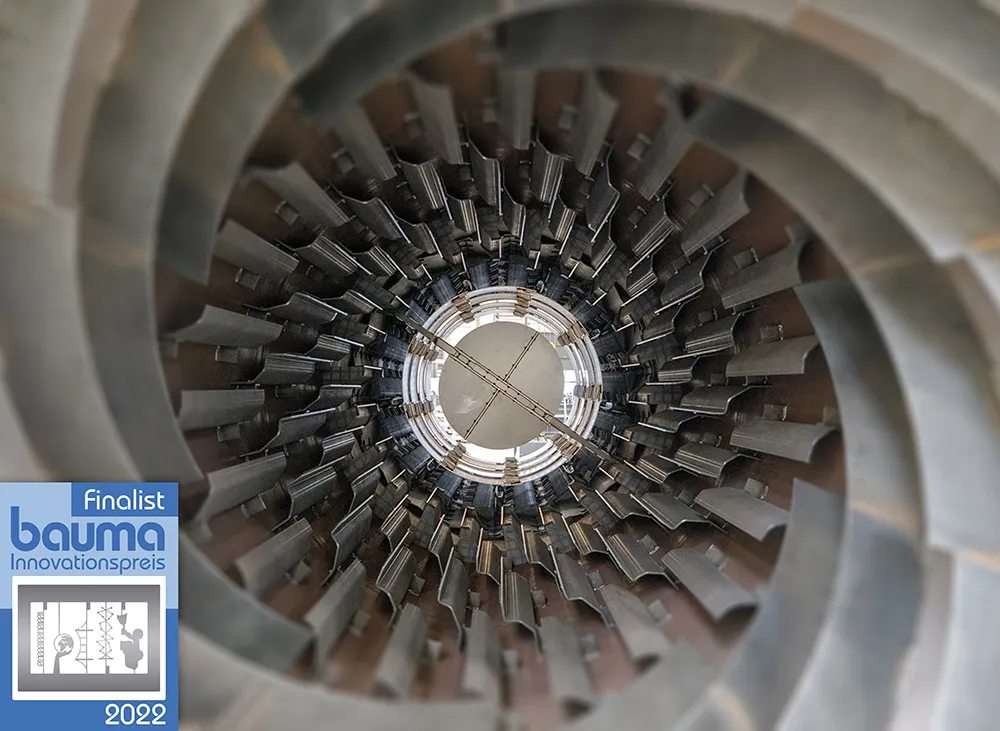

The new Promix system helps deliver an optimum mix design for all application needs. Promix is a measuring instrument composed of a stainless steel probe that is housed inside the mixer and supplied by a solar panel. A display in the cab receives information in real time, with its sensor providing details on the slump, temperature, moisture and rotational speed of the concrete mixer, as well as indicating when the mix is ready. The data is updated every 10 seconds and shown on the display. Mix data can be stored in an external computer or sent to other mobile devices via the GPS network.