It is the bugbear of motorists worldwide, and costs UK councils alone an estimated US$82.12 million (£50 million) in compensation each year.

Now Balfour Beatty is partnering with specialist supplier Velocity and North Somerset Council in south-west England to tackle potholes using innovative technology which vastly reduces disruption to road users. The method, called ‘Spray Injection’ patching, is allowing Balfour Beatty to repair nearly 700 potholes a week on its highways maintenance contract repairing

May 13, 2014

Read time: 3 mins

It is the bugbear of motorists worldwide, and costs UK councils alone an estimated US$82.12 million (£50 million) in compensation each year.

Now1146 Balfour Beatty is partnering with specialist supplier Velocity and North Somerset Council in south-west England to tackle potholes using innovative technology which vastly reduces disruption to road users. The method, called ‘Spray Injection’ patching, is allowing Balfour Beatty to repair nearly 700 potholes a week on its highways maintenance contract repairing and upgrading North Somerset’s roads. The method is also being used on the company’s contract in Herefordshire and is being considered for roll-out to other highways maintenance operations.

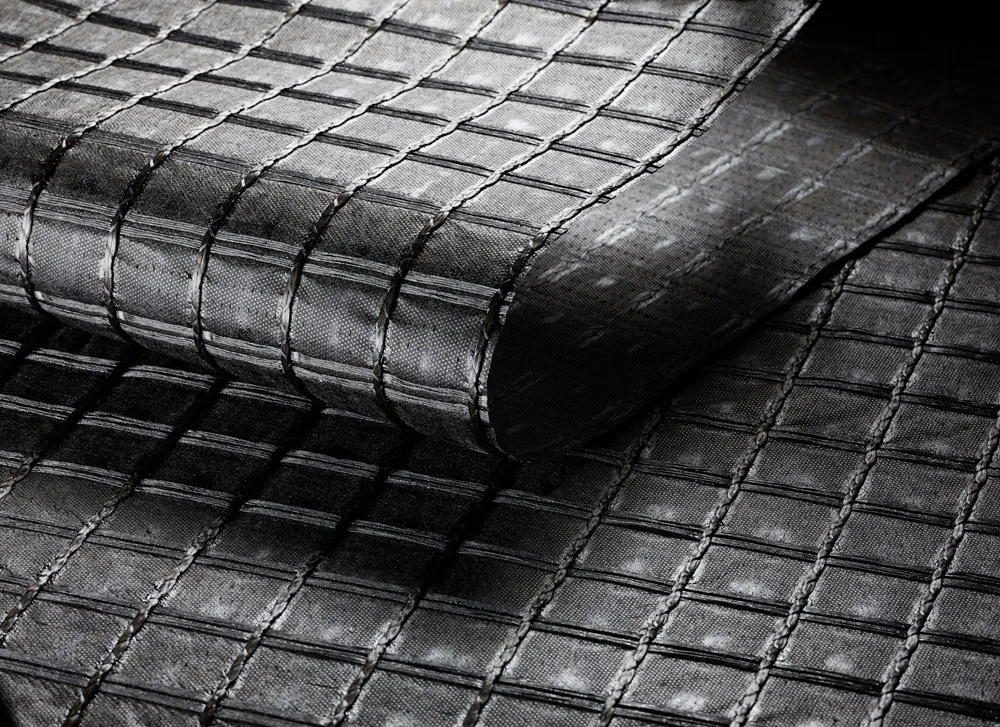

The Velocity unit is a mobile mixing plant carrying high-grade road aggregate and bitumen emulsion which is controlled by the specialist operator. The first stage of the process has the defect cleaned and dried with warm air from the delivery hose. A bond coat is then sprayed into the cracks and crevices of the defect to seal and stop ingress of water to the road base then a controlled flow of fully coated aggregate is introduced to remove the defect. The repair is then compacted and swept.

Using this approach, potholes are said to be repaired in around three minutes, compared to up to an hour using more conventional methods. Costs are significantly lower, as is the environmental impact of repairing defects.

Steve Helliwell, operations director at Balfour Beatty Living Places said, “Repairing potholes is a major priority for us and our local authority clients. We understand that poor road conditions are a major frustration for motorists, as are delays caused by the essential work to repair and maintain the network.

“We’re very pleased with the performance of this technology, which is another important tool in our work to maintain the country’s highways. It allows us to carry out work quickly and safely, and also provides a better method of undertaking proactive preventative work to reduce surface deterioration.

“Of course, there is no single magic solution to potholes. But Balfour Beatty is committed to continuing to explore and deploy new methods where we think they will help to tackle this ongoing issue.”

Councillor Elfan Ap Rees, North Somerset Council’s executive member for highways, said, “We have been very pleased with the initial results of this innovative answer to pothole patching, which is enabling us to better keep pace with the problem across North Somerset, speeding up the process and allowing us to respond more quickly and efficiently to residents’ concerns.”

Phill Lewis, sales manager at Velocity, said, “Velocity is confident that the process is a cost-effective productive solution for the rural network. By working closely with Balfour Beatty on preventative programmes of maintenance, we can stop further deterioration of the unclassified network, which sometimes receives less attention than larger roads.”

Now

The Velocity unit is a mobile mixing plant carrying high-grade road aggregate and bitumen emulsion which is controlled by the specialist operator. The first stage of the process has the defect cleaned and dried with warm air from the delivery hose. A bond coat is then sprayed into the cracks and crevices of the defect to seal and stop ingress of water to the road base then a controlled flow of fully coated aggregate is introduced to remove the defect. The repair is then compacted and swept.

Using this approach, potholes are said to be repaired in around three minutes, compared to up to an hour using more conventional methods. Costs are significantly lower, as is the environmental impact of repairing defects.

Steve Helliwell, operations director at Balfour Beatty Living Places said, “Repairing potholes is a major priority for us and our local authority clients. We understand that poor road conditions are a major frustration for motorists, as are delays caused by the essential work to repair and maintain the network.

“We’re very pleased with the performance of this technology, which is another important tool in our work to maintain the country’s highways. It allows us to carry out work quickly and safely, and also provides a better method of undertaking proactive preventative work to reduce surface deterioration.

“Of course, there is no single magic solution to potholes. But Balfour Beatty is committed to continuing to explore and deploy new methods where we think they will help to tackle this ongoing issue.”

Councillor Elfan Ap Rees, North Somerset Council’s executive member for highways, said, “We have been very pleased with the initial results of this innovative answer to pothole patching, which is enabling us to better keep pace with the problem across North Somerset, speeding up the process and allowing us to respond more quickly and efficiently to residents’ concerns.”

Phill Lewis, sales manager at Velocity, said, “Velocity is confident that the process is a cost-effective productive solution for the rural network. By working closely with Balfour Beatty on preventative programmes of maintenance, we can stop further deterioration of the unclassified network, which sometimes receives less attention than larger roads.”