The RWA 500 operates constantly perpendicular to the surface, even when the prime mover, a skidsteer wheeled loader, is at a slant.

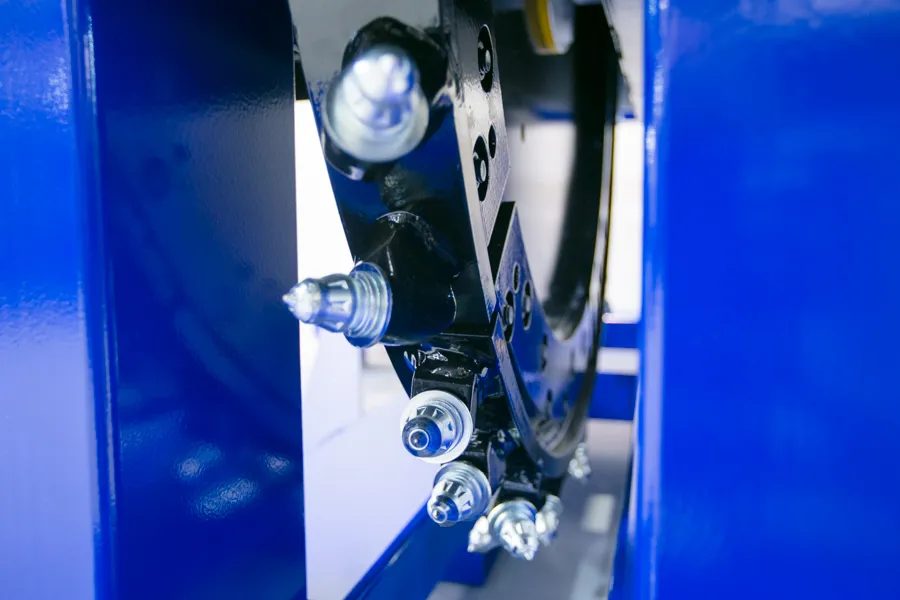

The RWA 500’s high productivity is a result of hydraulic piston motors in direct drive with the milling disk, which delivers maximum efficiency and a large cutting force.

Operators are assured good visibility because the excavation depth corresponds exactly and consistently to that programmed, thanks to Simex’s own self-levelling feature. The excavation depth is constant in any condition regardless of the pavement contour.

Also constant is the position of the attachment with respect to the prime mover – a skid-steer or small wheeled loader. The result is a continual trench depth exactly to specifications.

A clean trench at the set depth without the need for mounting a scraper, a solution that also results in a lighter weight.

The material excavated is discharged either to the right or left. But if necessary, excavated material can be conveyed to one side of the machine by simply closing one of the outlets.

This is an option that comes in handy when working at roadsides. The result is a clean trench at the set depth without the need for mounting a scraper, a solution that also results in a lighter weight.

The base disk with removable, interchangeable sectors permits the quick adjustment of the trench width without the need for replacing the entire element, thereby avoiding costly downtime of the machine.

Importantly, the full protection of the wheel at any working depth guarantees total safety for operators as well as property. These safety features make the attachment ideal for jobs in sensitive history sites and crowded city centres.