Ulma Construction said that it has designed the new SBU safety working platform to allow safe working with wall formwork at any height.

The SBU is composed of modular scaffolding BRIO components that are certified under the European Standards EN 12810-1/2 and EN 12811-1/2/3, which provide for safe working spaces and structures. The modularity of BRIO scaffolding components allows the SBU galvanised metal platform to adapt seamlessly to diverse geometries. The corner platform offers full coverage even at

July 6, 2016

Read time: 2 mins

Ulma Construction said that it has designed the new SBU safety working platform to allow safe working with wall formwork at any height.

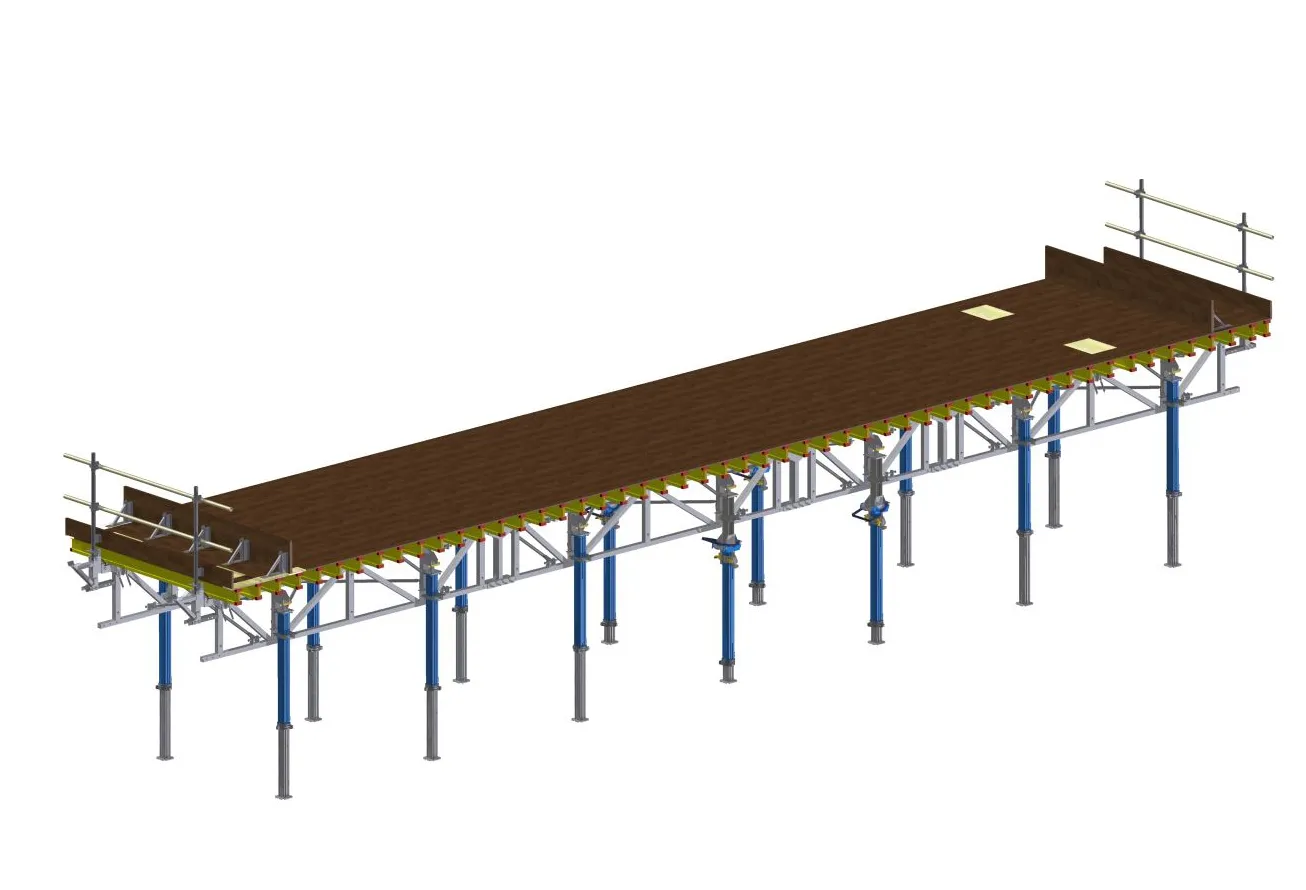

The SBU is composed of modular scaffolding BRIO components that are certified under the European Standards EN 12810-1/2 and EN 12811-1/2/3, which provide for safe working spaces and structures. The modularity of BRIO scaffolding components allows the SBU galvanised metal platform to adapt seamlessly to diverse geometries. The corner platform offers full coverage even at 90° corners and it adjusts to the most diverse geometries.

It can be assembled on the ground and be lifted together with the whole set of formwork panels and pipe braces to the upper floors. As such, it provides the worker with a high level of safety when working with formwork structures with the platform previously incorporated. The platforms feature an extensible corbel that allows for efficient stacking to save space during transport.

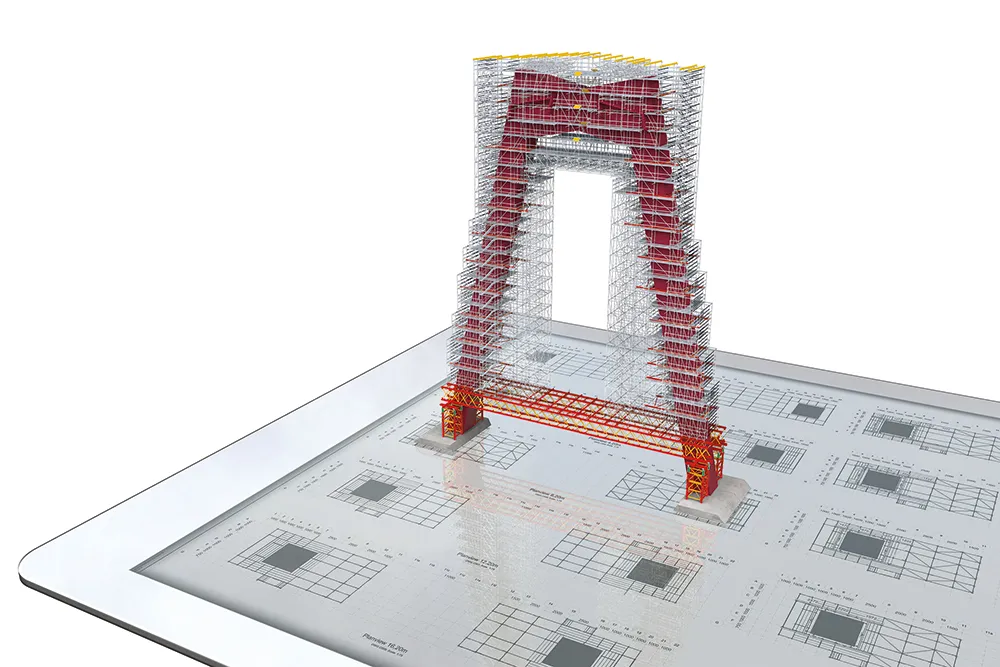

Ulma, as part of its customer service, said it will accompany each client from the start of every project until final construction, studying the formwork options for each site. Trained scaffolders apply all the protection measures required by law through the implementation of innovative security systems developed by Ulma.

The SBU is composed of modular scaffolding BRIO components that are certified under the European Standards EN 12810-1/2 and EN 12811-1/2/3, which provide for safe working spaces and structures. The modularity of BRIO scaffolding components allows the SBU galvanised metal platform to adapt seamlessly to diverse geometries. The corner platform offers full coverage even at 90° corners and it adjusts to the most diverse geometries.

It can be assembled on the ground and be lifted together with the whole set of formwork panels and pipe braces to the upper floors. As such, it provides the worker with a high level of safety when working with formwork structures with the platform previously incorporated. The platforms feature an extensible corbel that allows for efficient stacking to save space during transport.

Ulma, as part of its customer service, said it will accompany each client from the start of every project until final construction, studying the formwork options for each site. Trained scaffolders apply all the protection measures required by law through the implementation of innovative security systems developed by Ulma.