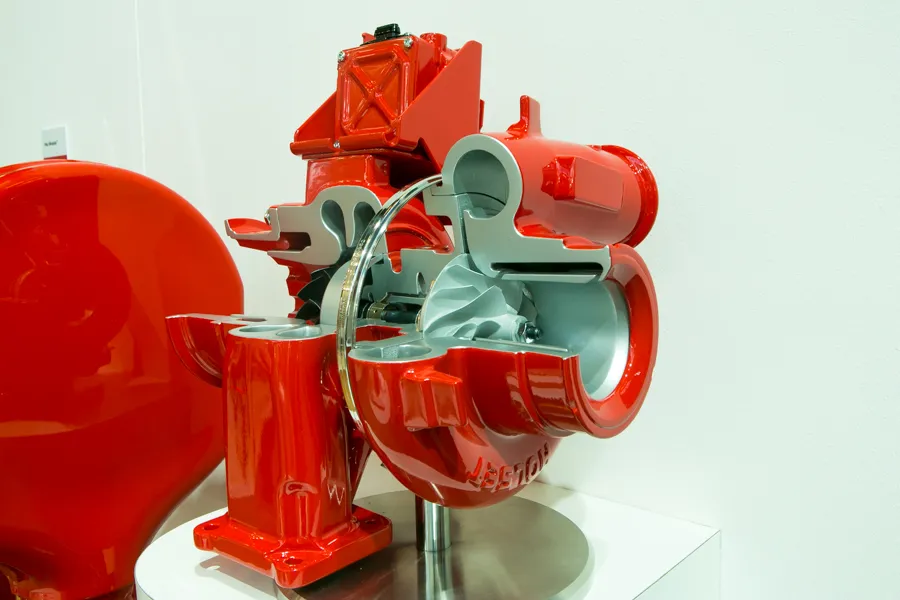

Cummins’ latest turbocharger innovation has been extended to the 500-series, with an electronically wastegated turbocharger that delivers efficiency gains of up to 8% as a result of changes to the exhaust turbine. By more closely matching turbine wheels to the compressor, greater fuel efficiency is achieveable, said the firm. The 500-series turbocharger is also said to offer improved resistance to oil leakage by 200% over the current industry standard.

April 24, 2018

Read time: 1 min