Altrad RMD Kwikform has launched a solution to reduce the effects of thermal loading - the Tubeshor Active Thermal Compensator, ATC.

The Tubeshor hybrid hydraulic shoring system is used for propping waler beams or capping beams of large excavations. Altrad RMD Kwikform, an above and below ground temporary works specialist, said it comes in a range of diameters to cater for all duties of shoring requirement.

An evolution of Tubeshor, the ATC Tubeshor accessory can reduce thermal loading by up to 90 percent compared to a mechanically locked-off prop, explained Ian Fryer, global product innovation director at Altrad RMD Kwikform.

Prop installation and pre-loading on site is carried out in the same way as for any standard proprietary prop; no special skills required. As Tubeshor ATC units are assembled directly into the prop makeup, standard prop end-fittings such as swivel units and spherical bearers can be used. Props can be installed into the excavation in the usual manner.

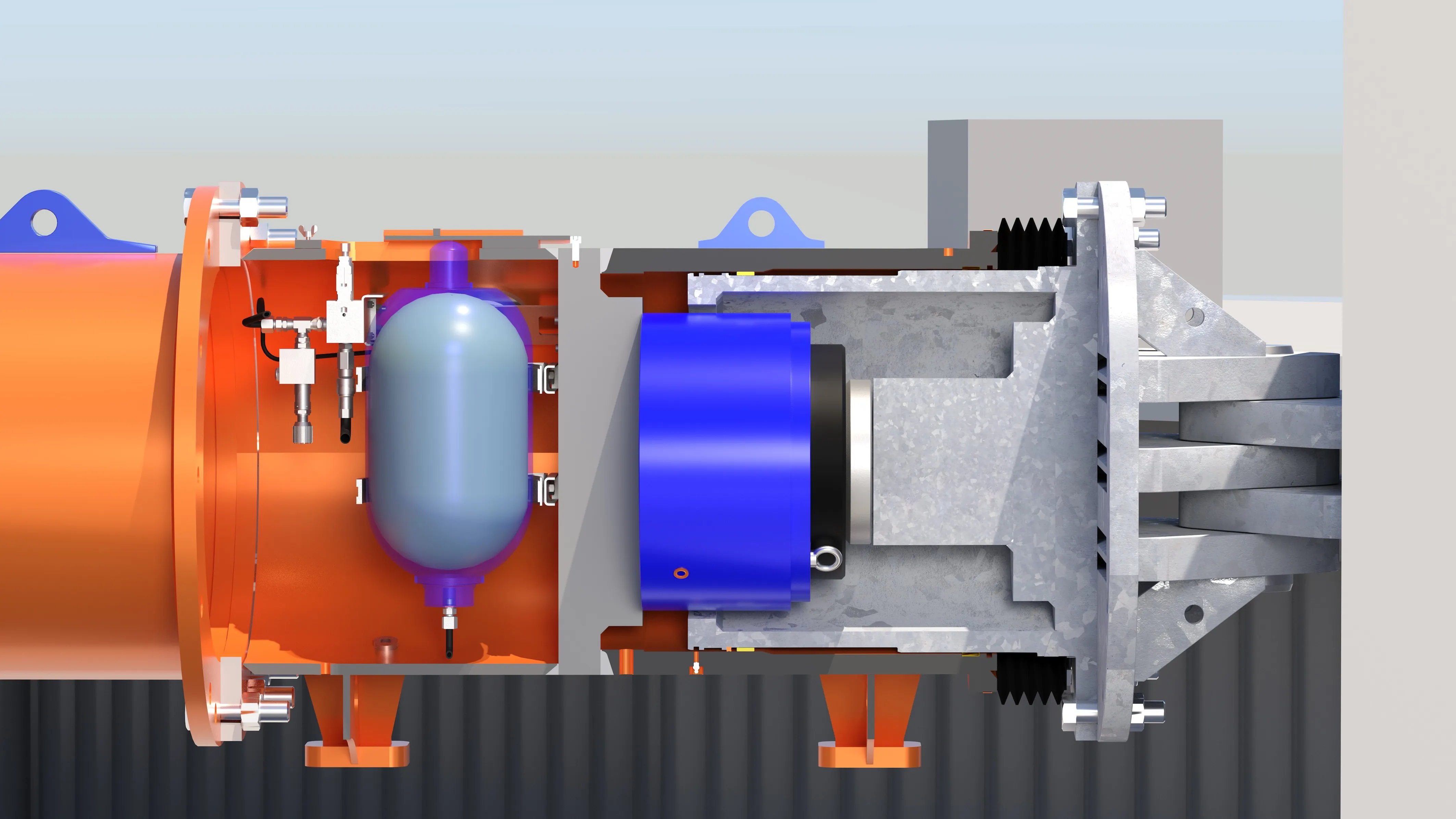

The Tubeshor ATC contains a 450-tonne hydraulic cylinder coupled to a bladder accumulator which is pressurised to suit the individual prop design geo-load before dispatch. Most of the time, the pressure in the accumulator exceeds that in the hydraulic system and normal prop stiffness results.

When higher temperature forces excessive prop thermal expansion, the compressed nitrogen in the accumulator comes into play and results in a phase of reduced prop stiffness. This means that a further increase in prop length resulting from thermal expansion does not result in the usual increase in prop load.

With less space taken up within the excavation, savings can be made on equipment, labour, transport and plant cost, as smaller plant can be used to install and remove the equipment.

Loads imposed on the permanent wall from the temporary props are reduced. This enables a lower cost wall design using less material and potentially reduces the volume of excavated soil, reducing project cost and further decreasing the carbon footprint.

The prop load can be read by direct inspection on site. There is also an option to use e-pins and wireless nodes to provide continuous prop load monitoring and data logging via a smartphone, tablet or laptop.