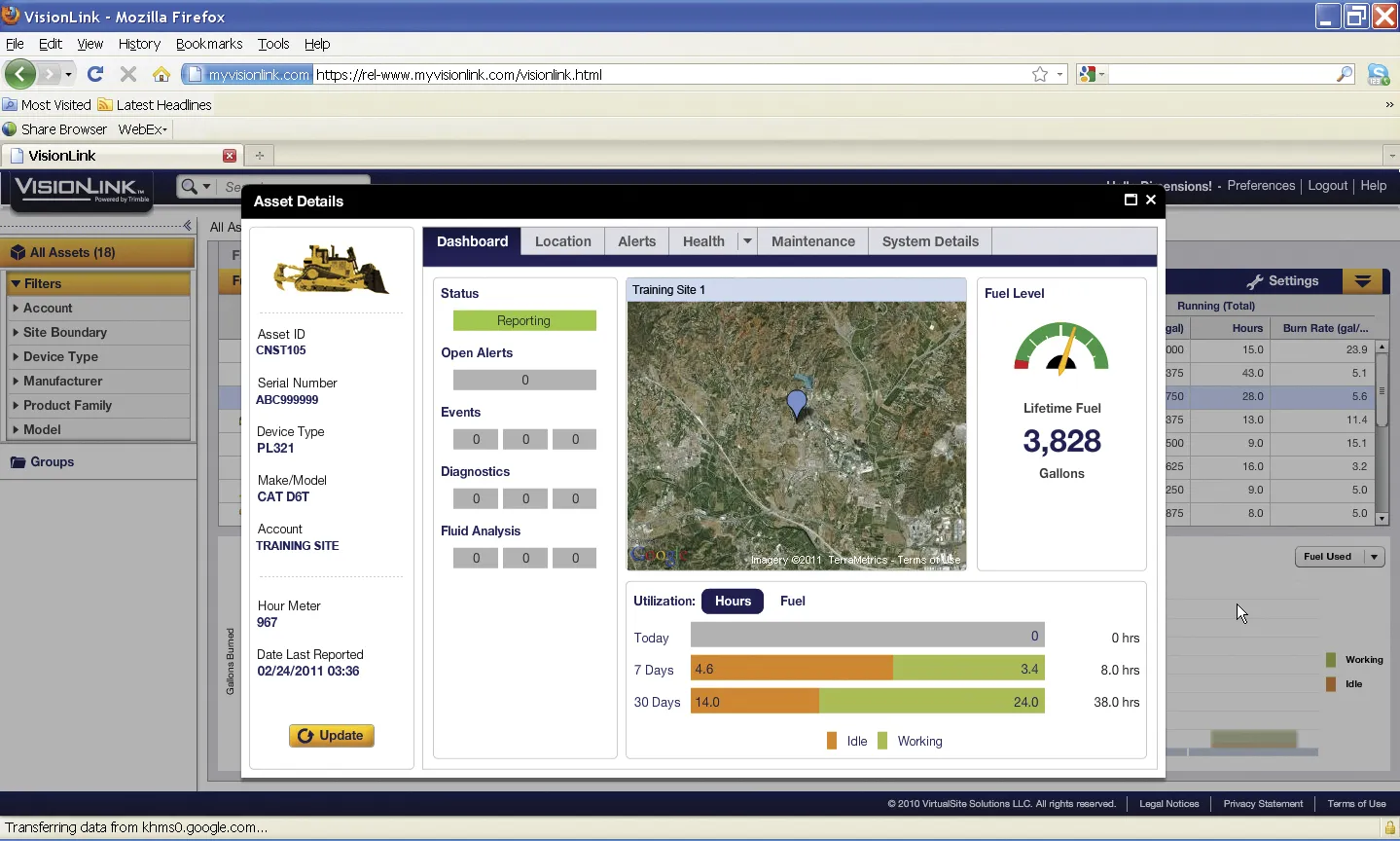

Trimble’s VisionLink, demonstrated at ConExpo 2014, shows how centralising and simplifying the management of on-site operations maximises efficiency, raises productivity and lowers costs for equipment fleets.

The web-based application allows contractors to quickly and easily view all their equipment, regardless of make, in a secure, web-based application.

Trimble says that VisionLink integrates site productivity, material quantities, and materials movement with asset and fleet management to give a holisti

January 6, 2017

Read time: 2 mins

The web-based application allows contractors to quickly and easily view all their equipment, regardless of make, in a secure, web-based application.

Trimble says that VisionLink integrates site productivity, material quantities, and materials movement with asset and fleet management to give a holistic view of a site so operators can make the right decision at the right time.

Indeed, the company says that using VisionLink, contractors with mixed fleets can, know when and where their equipment is working; monitor asset utilisation and minimise idle times to reduce equipment depreciation and eliminate unnecessary and costly fuel burn, and manage and make informed decisions about production efficiency.

Further benefits in seeing continuously updated surface models based on machine activity and scheduled reporting of business-critical information such as volume and quality assurance data for easier and more accurate billing, inspections and project progress.

The VisionLink Mobile application also allows contractors to view fleet and asset information in the field on their smartphone or tablet as well as locate assets, monitor utilisation and view asset alerts.

%$Linker: