Trimble says that its latest LOADRITE H2250 Haul Truck Monitor can help boost haulage efficiency in extraction operations. The new model is designed for use in rigid haul trucks and is an in-cab display and sensor system with an InsightHQ cloud reporting option for reporting.

The H2250 provides fast reporting of data for haul truck production, helping boost output while limiting costs. The system is designed to help quarry managers, supervisors and operators by presenting information to monitor and impro

March 23, 2017

Read time: 3 mins

The H2250 provides fast reporting of data for haul truck production, helping boost output while limiting costs. The system is designed to help quarry managers, supervisors and operators by presenting information to monitor and improve the processes and handling of the quarry haul fleet.

The firm says that the H2250 provides automatic haul truck load counting, and payload measurement to a high accuracy. The unit also features near real-time production reporting, truck speed monitoring, cycle time analysis and location based material tracking.

Using data from the H2250, fleet managers are able to make decisions of haul truck process improvements. Benefits include lowering transport costs by optimising payload, reducing cycle times and supporting safer truck operation.

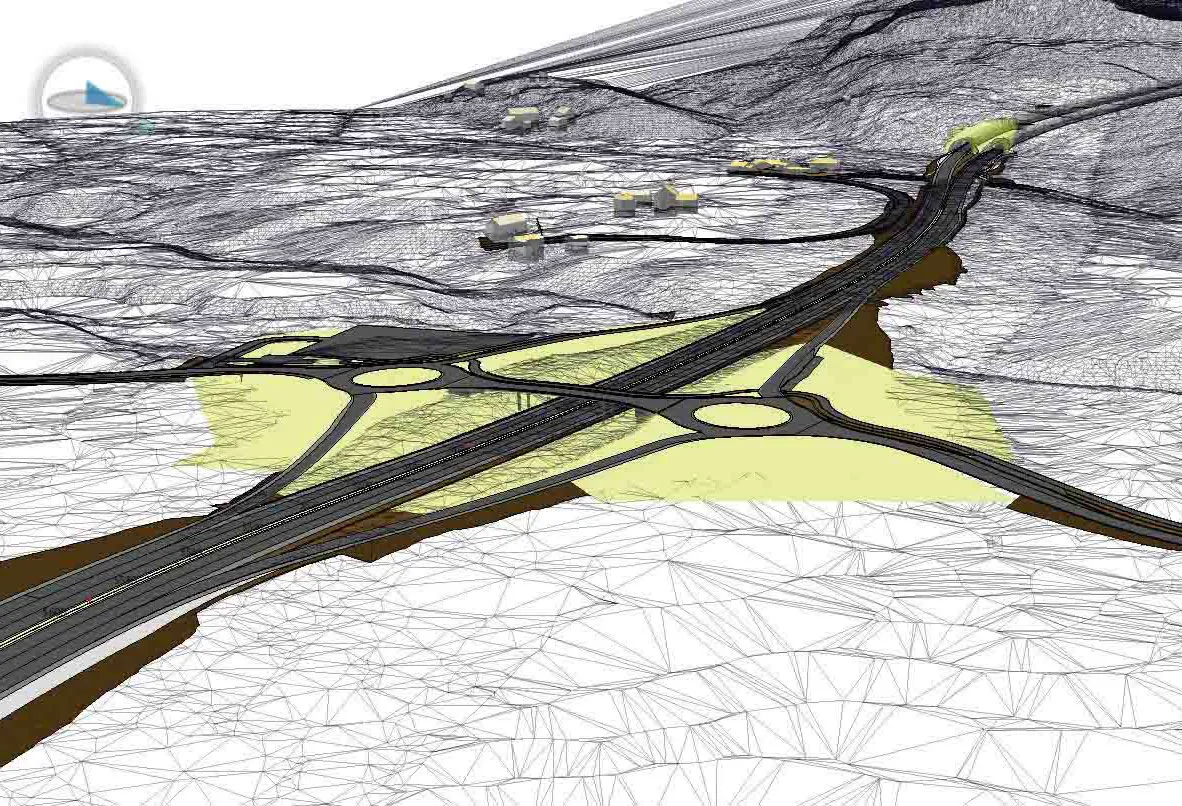

Trimble Loadrite general manager, Johan Smet explained that the system is designed specifically to boost economic and operation efficiency for extraction operations. The package also integrates into Trimble’s Connected Quarry system, providing site managers near real-time visibility across entire operations. This allows a manager to see how decisions affect operation as a whole, rather than just a single step in the process. Smet said that the haul truck monitoring system further adds to Trimble’s solutions for operations management.

Key benefits include productivity reports that give accurate production figures, removing the need for tally sheets and production estimates. The system also highlights material movement issues such as poor haul road construction and inefficient product movements. Cycle time reports include graphical reports of haul truck activity, loading time, haul time and queuing time. These show overall machinery availability and allow fleet managers to make improvements to boost production. Speeding reports overlay speeding events over quarry maps to identify operator skill gaps or haul road design issues to improve machine operation, fuel consumption and reduce machine wear. The dashboard shows cycle count and daily tonnage to help managers check their haul fleet is meeting plant demand, adjusting to changes in cycle time and product ratios. On screen alerts provide speeding, rollover, tray-up and overloading alerts.