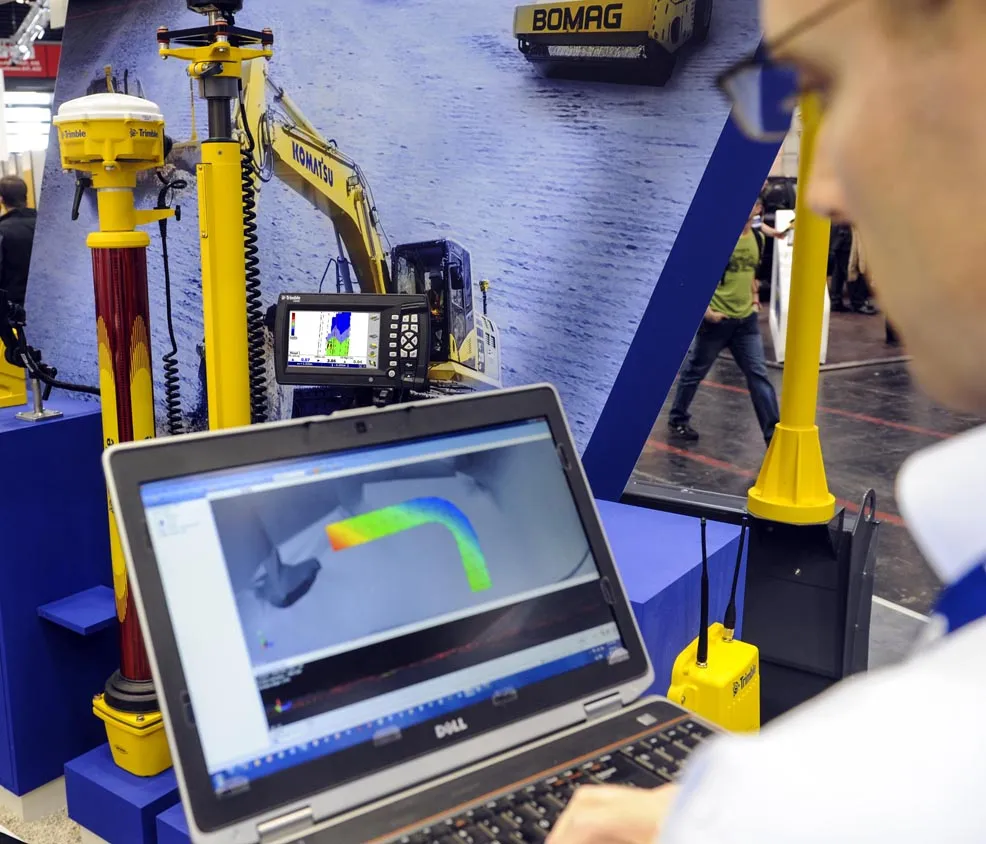

It is not about just knowing how much the trucks are carrying - but also delivery times between excavator and crusher, speeds along the roads, down times and safety information.

Quarry owners and site manager have full oversight of their processes, end to end. Drivers, too, have insight into their performance, thanks to an in-cab display and sensor system used in combination with InsightHQ cloud reporting and data analysis. It features near real-time production reporting, truck-speed monitoring, cycle-time analysis and location-based material tracking.

InsightHQ is a Web-based management portal accessible with any browser, including mobile devices. It consolidates live, operational information from Trimble Loadrite devices on other machines across the site, to provide near real-time productivity and performance reports for extraction, processing and load-out operations in quarries.

The H2250 provides automatic haul truck load counting and payload measurement typically within +/- 3% accuracy. It also features near real-time production reporting, truck-speed monitoring, cycle-time analysis and location-based material tracking.