Trimble says that its latest Connected Site solutions offer improved efficiency for connecting workers, machines and projects across the planning, design and construction lifecycle. These technologies suit use by heavy civil contactors and site preparation contractors.

Trimble’s mix of hardware, software and mobility technologies streamlines communication and collaboration throughout the construction lifecycle, from planning, design and site preparation through to the finished project. Connecting people

January 6, 2017

Read time: 3 mins

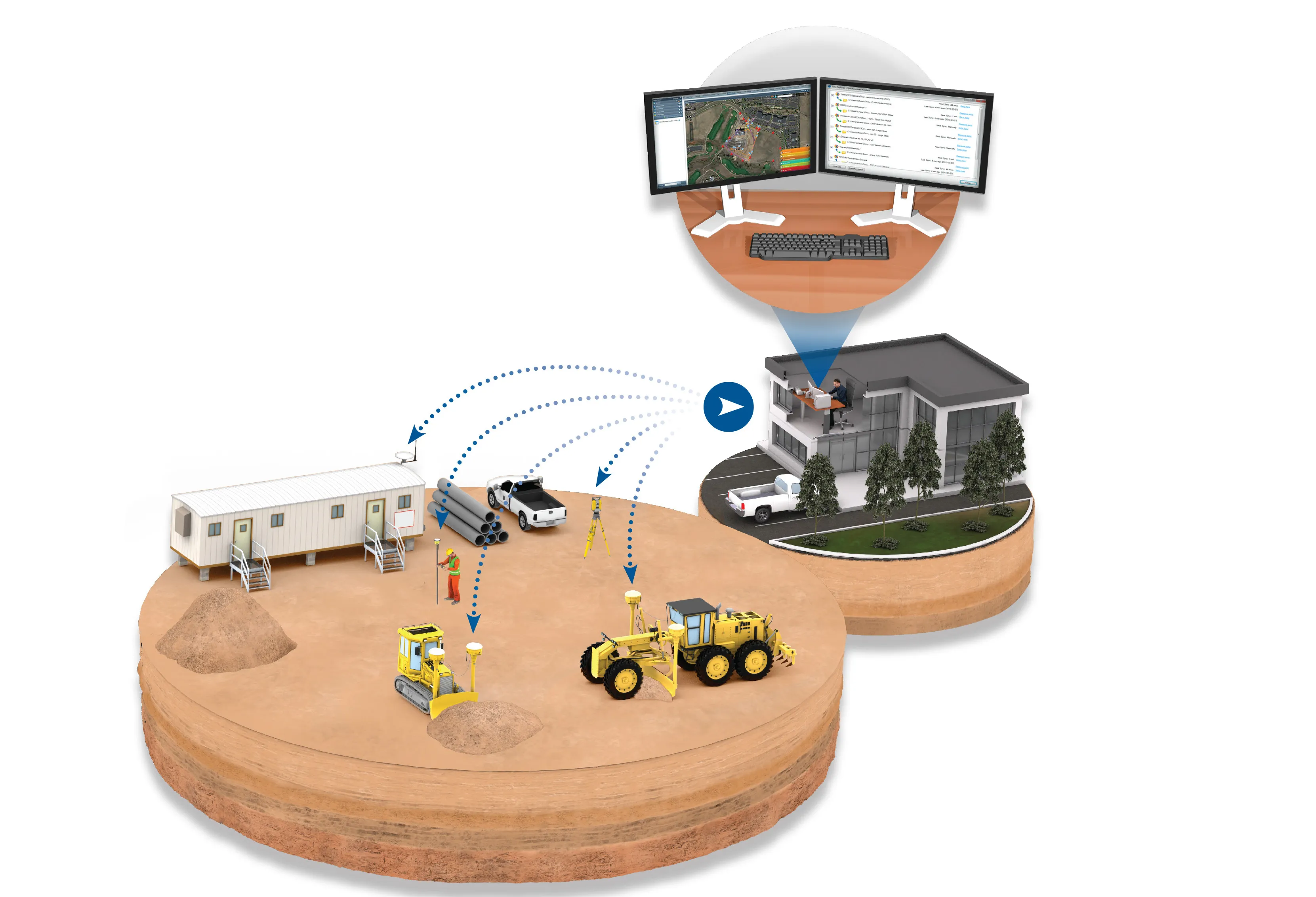

Trimble’s mix of hardware, software and mobility technologies streamlines communication and collaboration throughout the construction lifecycle, from planning, design and site preparation through to the finished project. Connecting people, machines and projects delivers real-time data to contractors and project stakeholders for enhanced information about material, people and asset utilization, resulting in improved productivity.

The latest capabilities provide now deliver greater quantities of accurate real-time information and data in the field, in the office and throughout the project. Boosting the information flow is said to enable contractors to achieve faster project completion with reduced costs, improved safety and lower environmental impact according to Trimble.

These solutions can improve the workflows of grading and excavating contractors, paving contractors, drilling and piling contractors, and site and utility contractors. The Connected Worker allows users to wirelessly synchronise data in the field with the office and receive GNSS corrections via the Internet. A grade checker, construction surveyor, supervisor and other field personnel can receive the 3D constructible design model, generate new measurements and send the measurement and stakeout results back to the office for review. Design changes originating in the office can be sent to field crews so they are updated with current information.

The Connected Machine offering is now standard in all Trimble Grade Control Systems and helps contractors manage assets and see what machines are doing. Machines can collect as-built measurement data for office delivery, and receive GNSS corrections using the Internet. A 3D constructible model created in the office can be sent to the machine operator for faster, more precise grading and earthmoving. The machine can be used for volume measurements, so expensive measurements by grade checkers occur less frequently.

With the Connected Project, contractors to build 3D construction models, perform data preparation and take-off, wirelessly synchronise data, monitor site productivity, and manage fleets and assets. The 3D design model can be sent to machines and controllers in the field, increasing efficiency, reducing rework and saving money. Additionally, a complete view of site productivity including materials quantity and movement, volume and compaction data, and fleet and asset management information can be shared across the organisation for better decision-making and communications.