Trimble has introduced the Trimble DPS900 Drilling and Piling System, a new machine control solution for drilling and piling contractors.

Part of the Trimble Connected Site portfolio, the new DPS900 system enables contractors to perform drilling and piling operations quickly, safely and accurately.

The new system can also help promote jobsite safety by minimising the need for stakes, construction surveying and personnel near the machine during drilling operations. The DPS900 system gives contractors

August 27, 2013

Read time: 2 mins

Trimble has introduced the Trimble DPS900 Drilling and Piling System, a new machine control solution for drilling and piling contractors.

Part of theThe new system can also help promote jobsite safety by minimising the need for stakes, construction surveying and personnel near the machine during drilling operations. The DPS900 system gives contractors the ability to precisely drill to the specified location, depth, orientation and inclination angle. Better rock fragmentation and minimised hauling costs are said by Trimble to be achievable by optimising drill hole spacing, angles and the location of the machine for a more even pattern of blasting. Reduced overdrilling means machine bits and hammers last longer, which can result in significant cost savings. In addition, machines can operate 24 hours a day, 7 days a week in almost any conditions so delays due to darkness or bad weather are minimised.

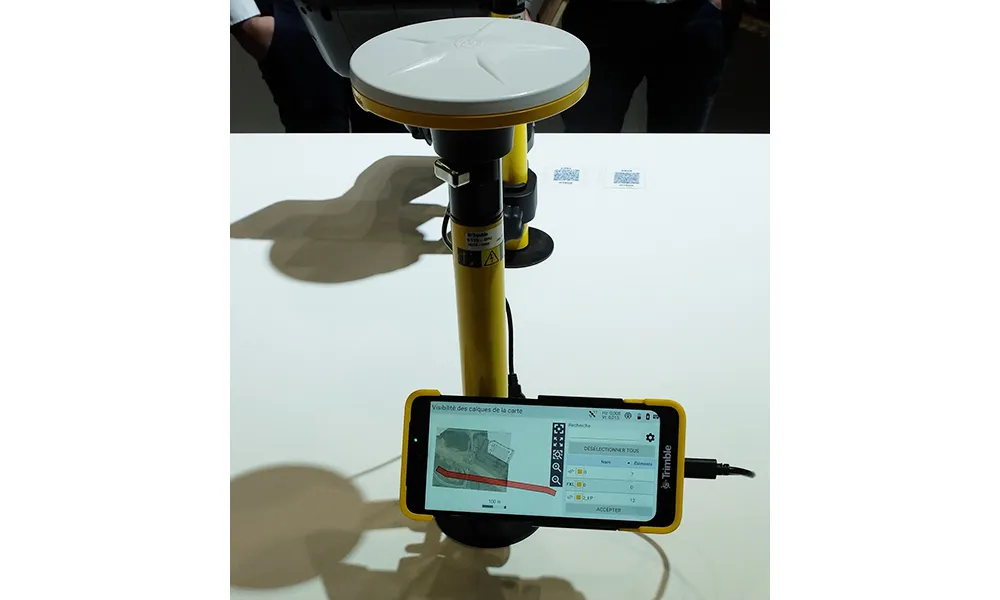

“The system is so easy to use, an experienced drill operator can become proficient in typically 30 minutes,” said Alan Sharp, business area director of Trimble Software Solutions and Specialist Construction Systems. “Engineered for ease of use, Trimble DPS900 features streamlined drilling and piling workflows and an intuitive user interface designed for construction environments.”

The integration of Trimble Business Center – HCE in the office and DPS900 in the field can increase efficiency and productivity of drilling and piling operations, says Trimble. Beginning with accurate job estimating and takeoff, drilling and piling contractors can have more confidence in their estimates by using Business Center – HCE office software. Once production begins, the new Business Center – HCE Drilling and Piling module offers contractors tools to rapidly create optimised drilling and piling plans. The drill plan is then wirelessly synced to the DPS900 system in the field, eliminating the need to drive to the site. To complete the project lifecycle, Business Center – HCE can be used for comprehensive quality and production reporting.

The new Trimble DPS900 Drilling and Piling System and Business Center – HCE v2.8 were due to be available in the third quarter of 2013 through Trimble’s SITECH Technology Dealer Channel.