Trimble is taking the concept of the building information model (BIM) one stage further with its development of its construction continuum concept. This is intended to show the process and benefits to building a construction-ready model embedded with intelligent data. Such a model can serve as the basis for how contractors plan and execute construction projects. With intelligent modeling, users can add and remove information in real time while simultaneously looking at multiple ways to perform construction

January 6, 2017

Read time: 3 mins

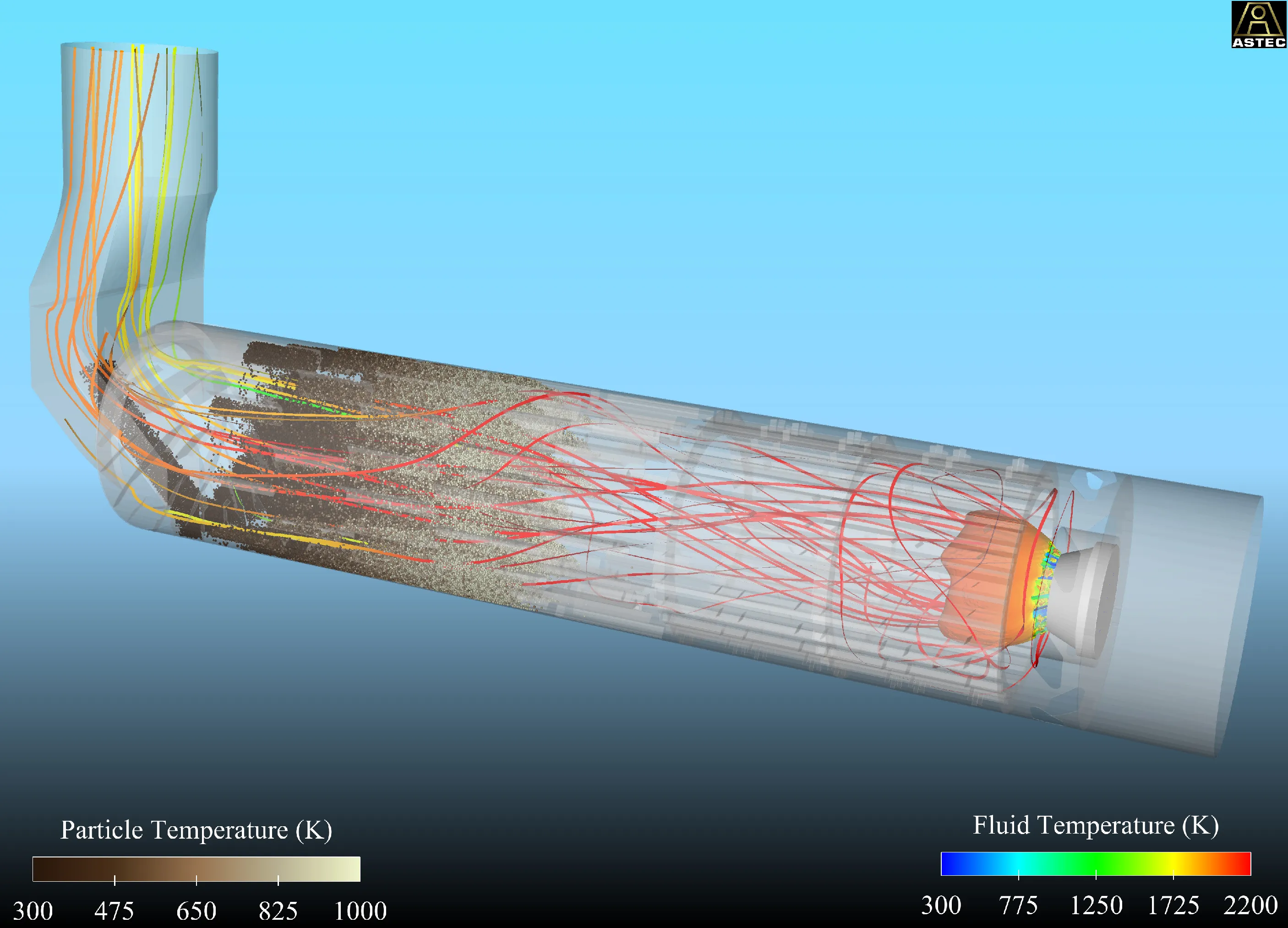

The construction continuum is Trimble’s vision for the construction workflow. This provides a living model with intelligent data that will serve as the foundation for how contractors plan and execute construction projects. This model is used throughout all stages of the project lifecycle, from the first stages of planning and estimating and bidding to detailed construction planning and execution. During this process, it will be continuously updated and enriched with more and more detailed information. Once the construction process is finished, the constructible model also serves as the basis for maintenance work and, eventually, for deconstruction. Through the constant information flow, it becomes a living model, a representation of the structure in the digital space.

The design phase of the continuum constructs in 3D so construction teams are delivered a construction-ready design. A constructible model is built with intelligent data that serves as the foundation of how contractors plan and execute construction projects. With intelligent modeling, users can add and remove information on the fly while looking at multiple ways to perform construction work. Building constructible models allows designers and engineers to run multiple scenarios quickly and easily that accurately translate to a constructible model that contractors can use for building.

Pairing interactive modeling with intelligent data frees engineers and architects to quickly analyse changes and design options in the physical environment. The potential impact is huge for saving time on rework, accelerating the building phase, and producing higher-quality projects.

Trimble also continues to expand its Connected Site capabilities to provide real-time information and data in the field, in the office and throughout the project. This extended capability better enables contractors to achieve faster project completion with reduced costs, improved safety and reduced environmental impact.

All videos