Rollers working in tandem will avoid duplicating passes with new Trimble CCS900 Compaction Control System.

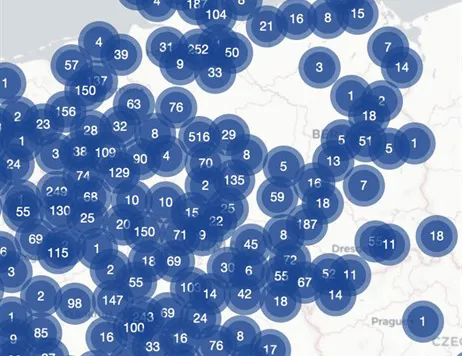

“With this system, the compactor operators share information at a new level,” said Dwayne Rosie, software sales engineer with the Heavy Civil Construction Division. “The colour mapping on the screen can be transferred from one machine’s screen to the other.”

The transfer is done in real-time, meaning each operator knows what area the other has covered. “It’s important on many jobsites, including thos

April 23, 2015

Read time: 2 mins

Rollers working in tandem will avoid duplicating passes with new 2122 Trimble CCS900 Compaction Control System.

“With this system, the compactor operators share information at a new level,” said Dwayne Rosie, software sales engineer with the Heavy Civil Construction Division. “The colour mapping on the screen can be transferred from one machine’s screen to the other.”

The transfer is done in real-time, meaning each operator knows what area the other has covered. “It’s important on many jobsites, including those where operators are working in tandem,” Rosie said. Previously, operators were able to map where they had been, but did not have immediate feedback about the coverage area of the other.

CCS900 version 12.7 utilises wireless data share. The machines communicate using a Wi-Fi network via the Trimble SNM940 Connected Site Gateway telematics device.

Besides sharing coverage areas, new layer management functionality allows operators to view the layers or lifts other compactors are working on. The real-time display of this information in the cab enables the operator to achieve more consistent compaction while also reducing the amount of under- and over-compacted areas.

This not only improves surface quality, but can also save time and fuel, according to Trimble. The mapping information is synchronized back to the office for progress monitoring and compaction documentation and reporting, using Trimble’s VisionLink asset management and project monitoring software.

The technology applies to soil, landfill and asphalt applications.

“With this system, the compactor operators share information at a new level,” said Dwayne Rosie, software sales engineer with the Heavy Civil Construction Division. “The colour mapping on the screen can be transferred from one machine’s screen to the other.”

The transfer is done in real-time, meaning each operator knows what area the other has covered. “It’s important on many jobsites, including those where operators are working in tandem,” Rosie said. Previously, operators were able to map where they had been, but did not have immediate feedback about the coverage area of the other.

CCS900 version 12.7 utilises wireless data share. The machines communicate using a Wi-Fi network via the Trimble SNM940 Connected Site Gateway telematics device.

Besides sharing coverage areas, new layer management functionality allows operators to view the layers or lifts other compactors are working on. The real-time display of this information in the cab enables the operator to achieve more consistent compaction while also reducing the amount of under- and over-compacted areas.

This not only improves surface quality, but can also save time and fuel, according to Trimble. The mapping information is synchronized back to the office for progress monitoring and compaction documentation and reporting, using Trimble’s VisionLink asset management and project monitoring software.

The technology applies to soil, landfill and asphalt applications.