Founded in 2014, Revotec is a young civil engineering practice specialising in structural dynamics, especially, but not exclusively, for railway bridges. Projects frequently involve fatigue assessments and vibration tests, for example on steel supporting structures that are excited artificially with electromechanical shakers.

"We're currently working on a project for Austrian Federal Railways (ÖBB) where – for the first time – we're using weigh-in-motion by Kistler to monitor a sensitive road bridge over a railway line and determine the real loads,” said Michael Vospernig, one of Revotec's two founders.

This small bridge is part of the access road to a village but because there is a large sawmill nearby, the bridge is crossed every day by many trucks carrying heavy loads of timber.

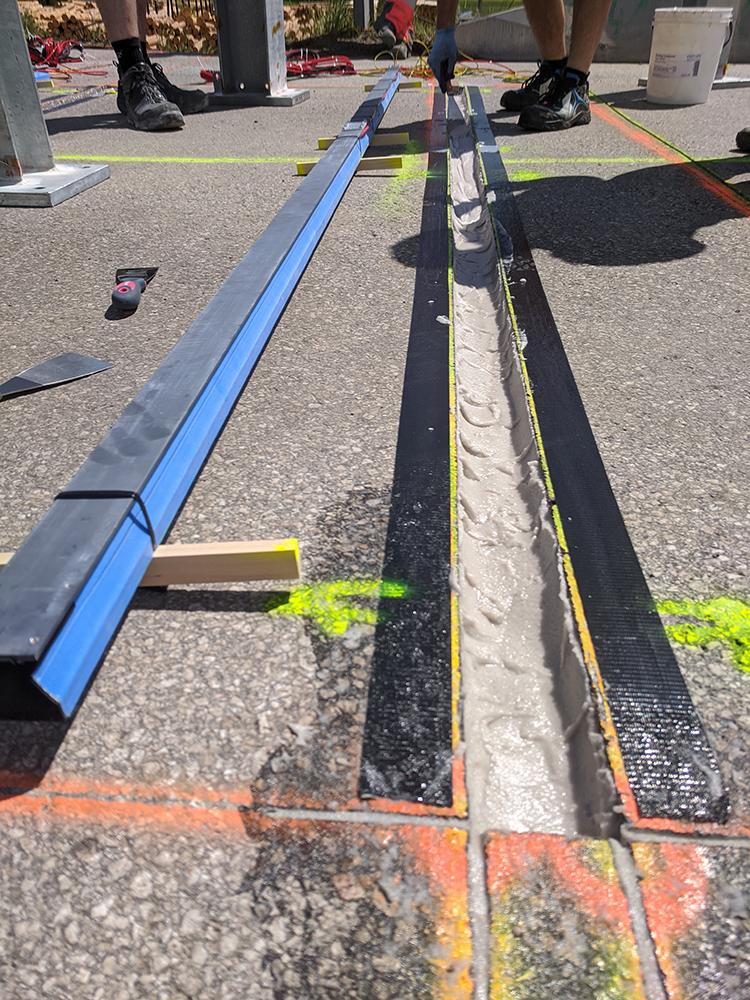

"When the project began in January 2020, there was already some visible damage to the bridge with several cracks in the supporting structure. On behalf of ÖBB, we installed the strain gauges for measurements of the supporting structure in March. Then in May, we added the axle load measurement with the system from Kistler and that installation was completed within one day.”

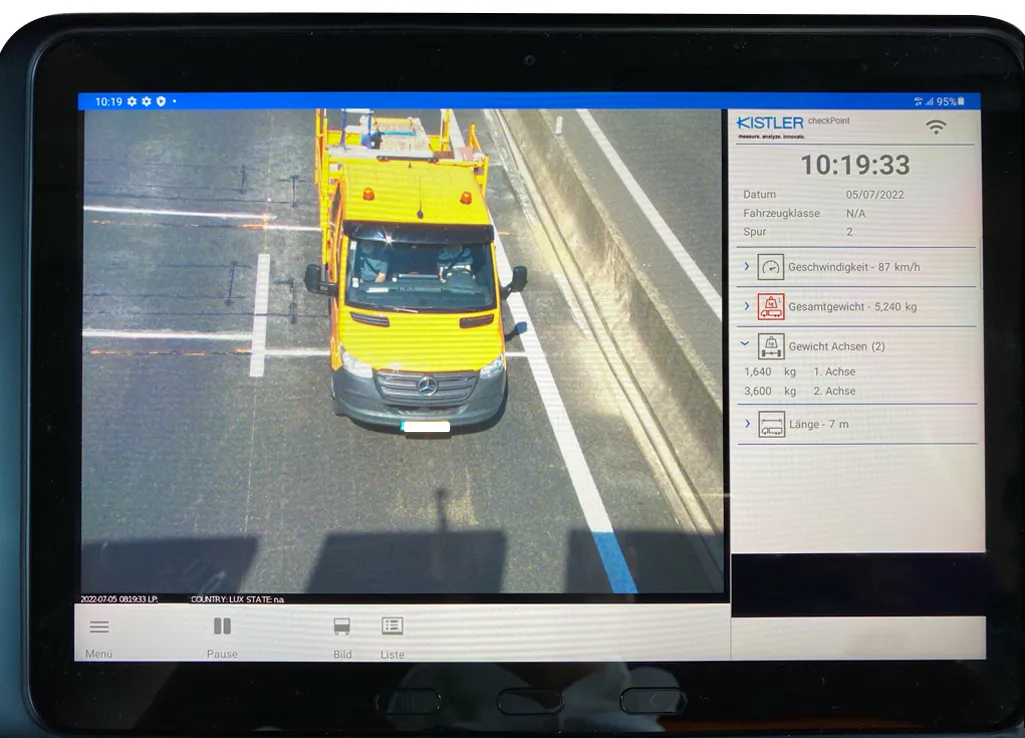

KiTraffic Statistics showed many of the trucks and tractors with trailers exceeded the overall weight limit of 40tonnes – sometimes by as much as five or 10 tonnes. Even vehicles weighing less than 40tonnes often had axle loads of more than 12.5tonnes - the maximum permitted in Austria. "Thanks to the data acquired, the authorities were able to penalise vehicles weighing over 44tonnes so as to prevent any further overloading of the bridge. But this couldn't be achieved overnight, because the legal basis for weigh-in-motion is still largely lacking," noted Vospernig.

The planned reconstruction of the bridge was also delayed due to unresolved land rights issues although construction is scheduled to start soon. This means that Kistler's WIM system has several important roles to play: reliable classification of vehicles and identification of overloads have now become possible and changes in the bridge's condition can also be determined more accurately in combination with measurements of the supporting structure.

"The system is efficient to use and CSV file export makes it simple to merge the data with the supporting structure measurements. In this case, the result was an almost linear correlation between the influencing factors and the effects on the supporting structure,” said Vospernig. “Thanks to the high quality and reliability of the data, this method of long-term measurement could even be applied to other bridges."

Despite some fierce resistance from haulage companies and transporters, the local authorities were ultimately successful in preventing virtually any further overloading of the bridge. Later, Revotec installed a camera system with vehicle numberplate recognition in order to extend the "long arm of the law". The WIM measurements were backed up by spot measurements using a mobile vehicle weighing system on behalf of ÖBB and in cooperation with the authorities.

Vospernig believes that applications could include projects by ASFINAG, the Austrian Motorway and Expressway Financing Corporation, focusing on traffic data acquisition and bridge monitoring. "KiTraffic Statistics delivers highly reliable data – the system is simple to set up and its cost-to-benefit ratio is good. Users can do a lot of the work themselves with the help of the instructions. Good contact with Kistler Austria and personal onsite support with the setup were extra benefits."

Meanwhile, the demand for data-based systems is on the increase, explains Vospernig. Individual solutions continue to dominate the market at present, but there could be a trend towards modular systems and even turnkey solutions in the medium term. “At some point in the future, automated systems to measure supporting structures and axle loads are likely to become part of the infrastructure. They would allow real-time condition monitoring and predictive maintenance, based on degradation lines and at varying intervals," he said.