The i33 is Topcon’s cutting-edge economical and multi-platform 3D indicate grade system. The new system features GPS technology and a graphical display to provide a powerful indicate system at an economical price.

January 6, 2017

Read time: 2 mins

The i33 is 342 Topcon’s cutting-edge economical and multi-platform 3D indicate grade system. The new system features GPS technology and a graphical display to provide a powerful indicate system at an economical price.

Kris Maas, Topcon’s manager of machine control product marketing, said the i33 is designed for quick installation and easy operation on many types of grading and earthmoving machinery. “The i-33 is Ideal for use on a dozer, scraper or virtually any type of machinery used for cut or fill operations. This new system brings the productivity of GPS-based 3D grade control for all types of applications.”

Maas said that deploying indicate GPS systems had not traditionally been economical for many contractors or types of work. “In other words, the payback for a traditional 3D-MC system did not make it practical for bulk earthmoving or less utilised equipment,” he added. “With i-33, the game has changed. Its low cost and quick installation make it the perfect solution for setting up multiple pieces of equipment or even sharing between machines. Basically, it eliminates over or under-cutting and ensures material is moved exactly where it needs be the first time.”

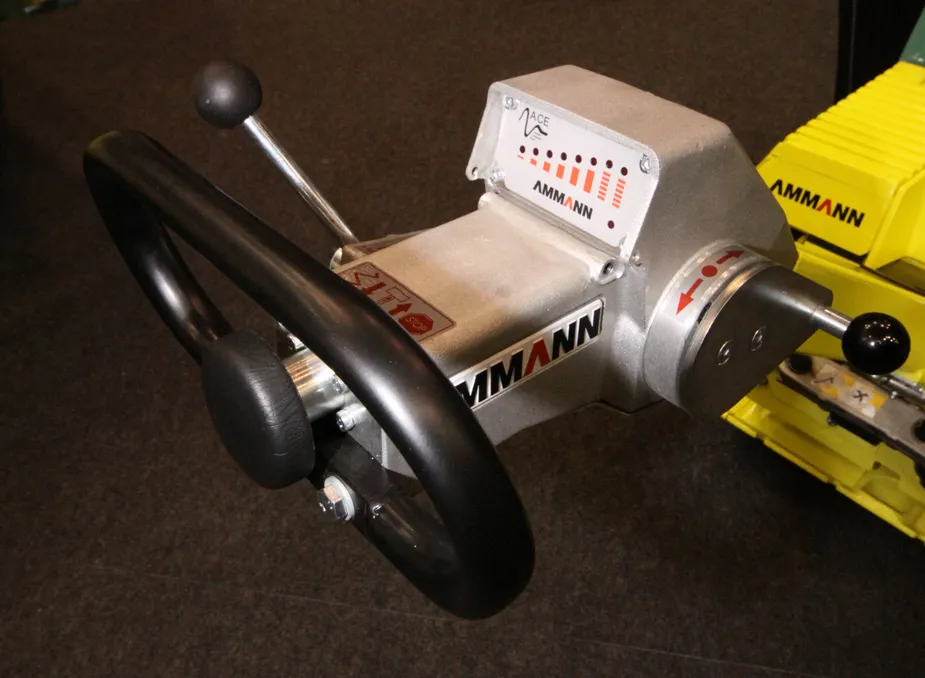

The i33’s GX-30 graphical display control box keeps the operator visually informed as to final grade so adjustments can easily be made, eliminating redundant passes and helping to further reduce the need for onsite grade checking.

The system also includes the new MC-i3 GNSS receiver with Vanguard technology offering single or dual GNSS antenna configurations, allowing the system to work in a wide variety of applications. The MC-i3 also allows connection to Topcon’s Sitelink3D site management solution that provides real-time data control, machine tracking, reporting and planning in one solution to maintain conformance and improve productivity through all job phases.

Stand: N-12966

Stand: S-3349

Stand: S-65215%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 48696 0 oLinkExternal www.topconpositioning.com Topcon Positioning Systems website false /EasySiteWeb/GatewayLink.aspx?alId=48696 false false %>

Kris Maas, Topcon’s manager of machine control product marketing, said the i33 is designed for quick installation and easy operation on many types of grading and earthmoving machinery. “The i-33 is Ideal for use on a dozer, scraper or virtually any type of machinery used for cut or fill operations. This new system brings the productivity of GPS-based 3D grade control for all types of applications.”

Maas said that deploying indicate GPS systems had not traditionally been economical for many contractors or types of work. “In other words, the payback for a traditional 3D-MC system did not make it practical for bulk earthmoving or less utilised equipment,” he added. “With i-33, the game has changed. Its low cost and quick installation make it the perfect solution for setting up multiple pieces of equipment or even sharing between machines. Basically, it eliminates over or under-cutting and ensures material is moved exactly where it needs be the first time.”

The i33’s GX-30 graphical display control box keeps the operator visually informed as to final grade so adjustments can easily be made, eliminating redundant passes and helping to further reduce the need for onsite grade checking.

The system also includes the new MC-i3 GNSS receiver with Vanguard technology offering single or dual GNSS antenna configurations, allowing the system to work in a wide variety of applications. The MC-i3 also allows connection to Topcon’s Sitelink3D site management solution that provides real-time data control, machine tracking, reporting and planning in one solution to maintain conformance and improve productivity through all job phases.

Stand: N-12966

Stand: S-3349

Stand: S-65215%$Linker: