A spokesperson for the firm said, “The crew on the machine can see what trucks are coming and when they’ll arrive.”

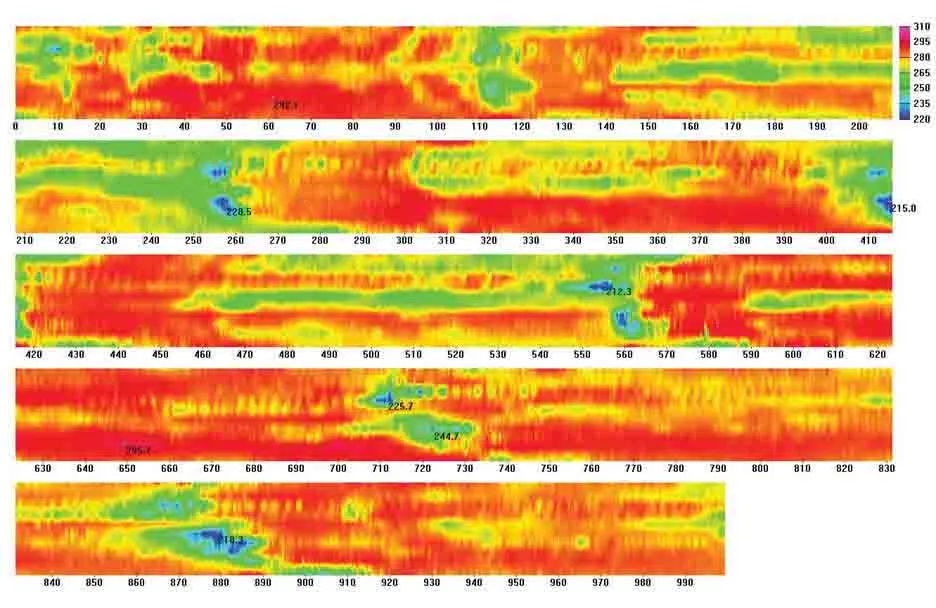

Sensors are installed on the paver and are mounted on the hopper and at the augers feeding the screed, showing the temperature of the mix as it goes through the machine. The combination of temparature sensors and location technology provides an accurate picture of the temperature gradient of the

mat as it is paved, showing any heat segregation and recording the data in the cloud for future use.

The system is of particular importance for warm mix applications, where the temperature window can be more critical. It allows the paving crew to make informed decisions and the compactor operators can prioritise areas needing attention first for example.

Data on the compaction carried out is also recorded from each of the rollers, with the system providing a comprehensive picture of what work was carried out, and when, recording quantities of materials used for each layer, as well as temperatures.