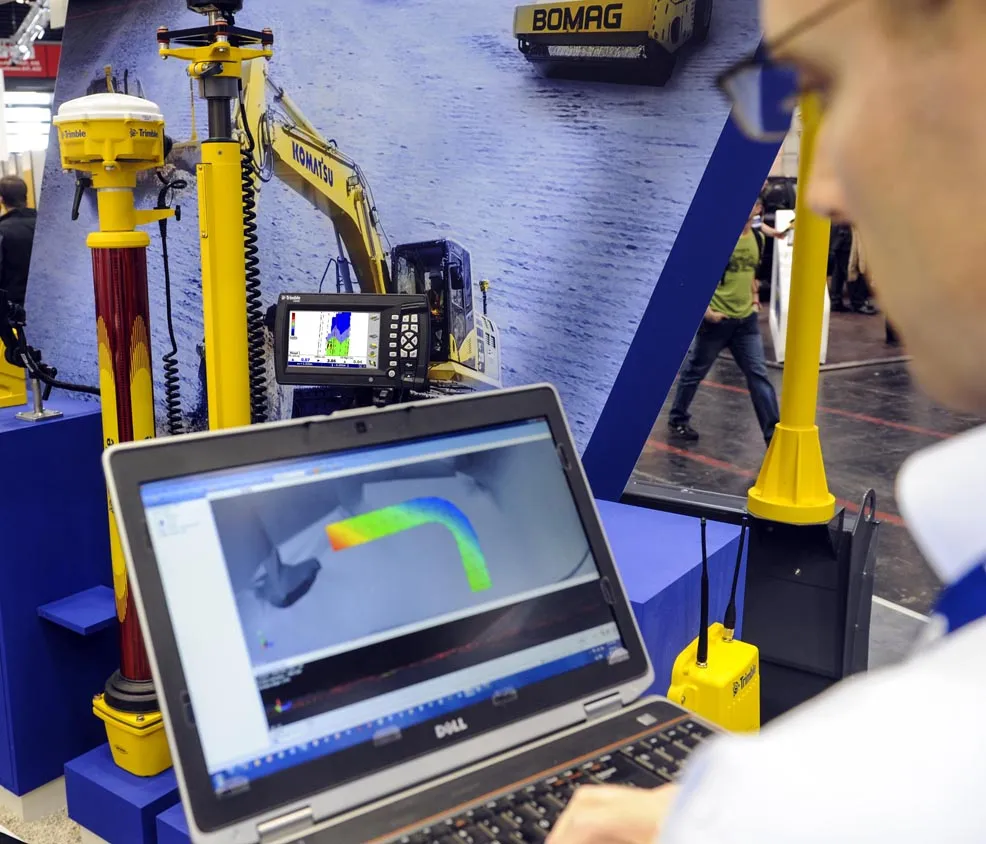

Topcon’s new X-63i 3D indicate system for excavators is the latest addition to its machine control portfolio. “The new system combines Topcon’s advanced GNSS global positioning technology and machine sensors with the heavy-duty GX-60 touchscreen colour display to provide an easy-to-use system for increased excavation efficiency,” said Kris Maas, Topcon’s machine control product marketing manager.

February 25, 2014

Read time: 2 mins

“The new system combines Topcon’s advanced GNSS global positioning technology and machine sensors with the heavy-duty GX-60 touchscreen colour display to provide an easy-to-use system for increased excavation efficiency,” said Kris Maas, Topcon’s machine control product marketing manager.

The X-63i is upgradeable to Topcon’s fully automatic excavator systems. Additionally, the system’s MC-i3 GNSS receiver is Sitelink3D ‘ready’ providing the option of integration into Topcon’s real-time job site management solution.

Maas added, “Topcon’s X-63i provides the operator with all the information needed to expedite excavation tasks. The X-63i enables the operator to ‘see’ the machine’s exact position in relation to the site, enabling precise positioning over utility centre lines. In real time, the operator can also see the position of the teeth of the bucket compared to the finish design which is very helpful in deep cuts, blind excavations or when working around structures. Simply put, X-63i gets you to grade faster and keeps you there.”

%$Linker: