In the spirit of Industry 4.0, PERI offers a comprehensive service and product portfolio of digital solutions that facilitate the working world in construction. PERI supports, automates and simplifies work processes and sustainably increases efficiency in every phase of the construction process – from planning and organisation to implementation.

Every project first starts with a plan – because the right planning is the foundation for the project’s success. With QuickSolve, PERI offers the user an application for quick and easy layout planning. The web-based tool is accessible at any time – no software download is required. You can enter ground plans into the software and create balanced cycles using the cycle overview. The formwork solution is either taken from the user's inventory or as the best possible suggestion from the app. Construction site-specific parts lists are then output, as well as 2D and 3D views of the matching solutions. In addition, PERI QuickSolve contains detailed information on supported wall heights, wall thicknesses and much more.

With the PERI component library, users of BIM software receive the full article catalogue for many PERI wall, slab and column formwork systems, as well as for scaffolding components together with their accessories. All of the components are provided with the relevant meta data and, in terms of building information modelling, can be used repeatedly during the construction process. This gives the planner the necessary transparency to use their components more efficiently.

In terms of execution, PERI is able to improve the efficiency and significantly increase the productivity of projects by deploying and providing support for the most sophisticated BIM methods and technologies. By having all personnel, processes and tools interact with each other throughout the entire project cycle, it is possible, for example, to minimise the requirement for reworking operations in the execution phase by way of optimised planning, therefore reducing costs. The online client portal myPERI is also a comprehensive information platform and meets information requirements throughout the entire execution phase of a project.

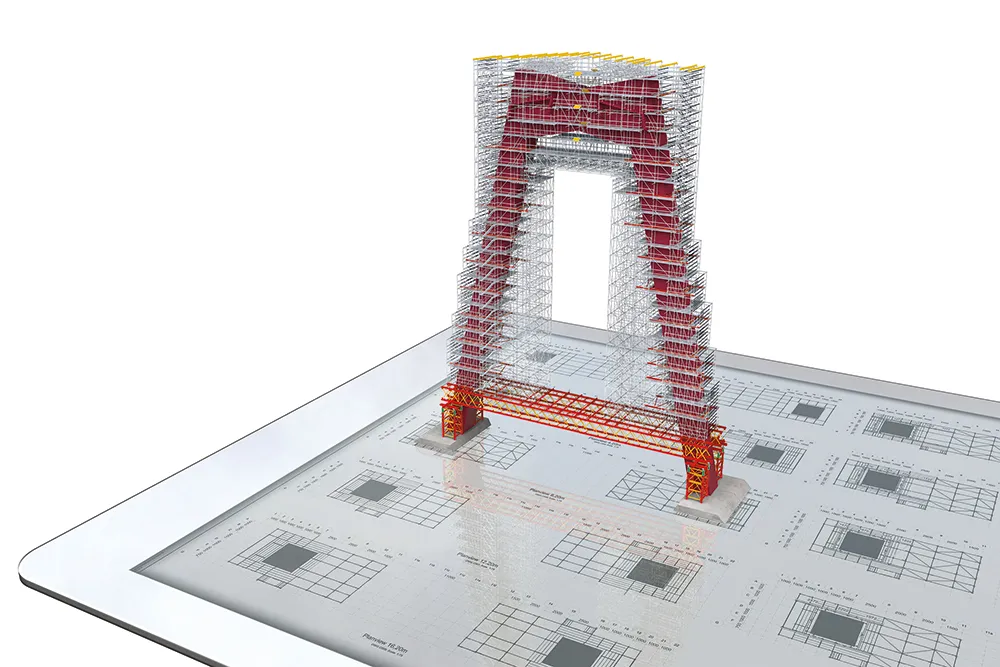

Visualisation plays an increasing role in all stages of the construction process. The communication, security and efficiency of many processes all benefit from virtual models. With the PERI Extended Experience App, PERI takes the mobile 3D visualisation of construction projects to a new dimension. By means of augmented and virtual reality, PERI planning can be virtually walked through or projected into the physical environment. The virtual and real worlds start to merge with one another. Respective models can be optimally integrated into the planning and construction process using different visualisation options. The app is available for both Android and iOS.

For the economic efficiency of a construction site, it is of great importance to design construction processes that are also transparent during implementation. The more information that is available, the better the progress of the site. PERI therefore offers a wide range of sensors to provide assurance about material conditions. The PERI InSite Construction (ISC) concrete temperature and strength system measures the temperature at different points in the concrete and then transmits the data directly to the user via a web application. This eliminates the need for time-consuming manual readout and recording of the measuring points during the concreting process. The PERI temperature sensor cable can be fixed in any area of the reinforcement prior to concreting.

Sponsored content produced in association with PERI