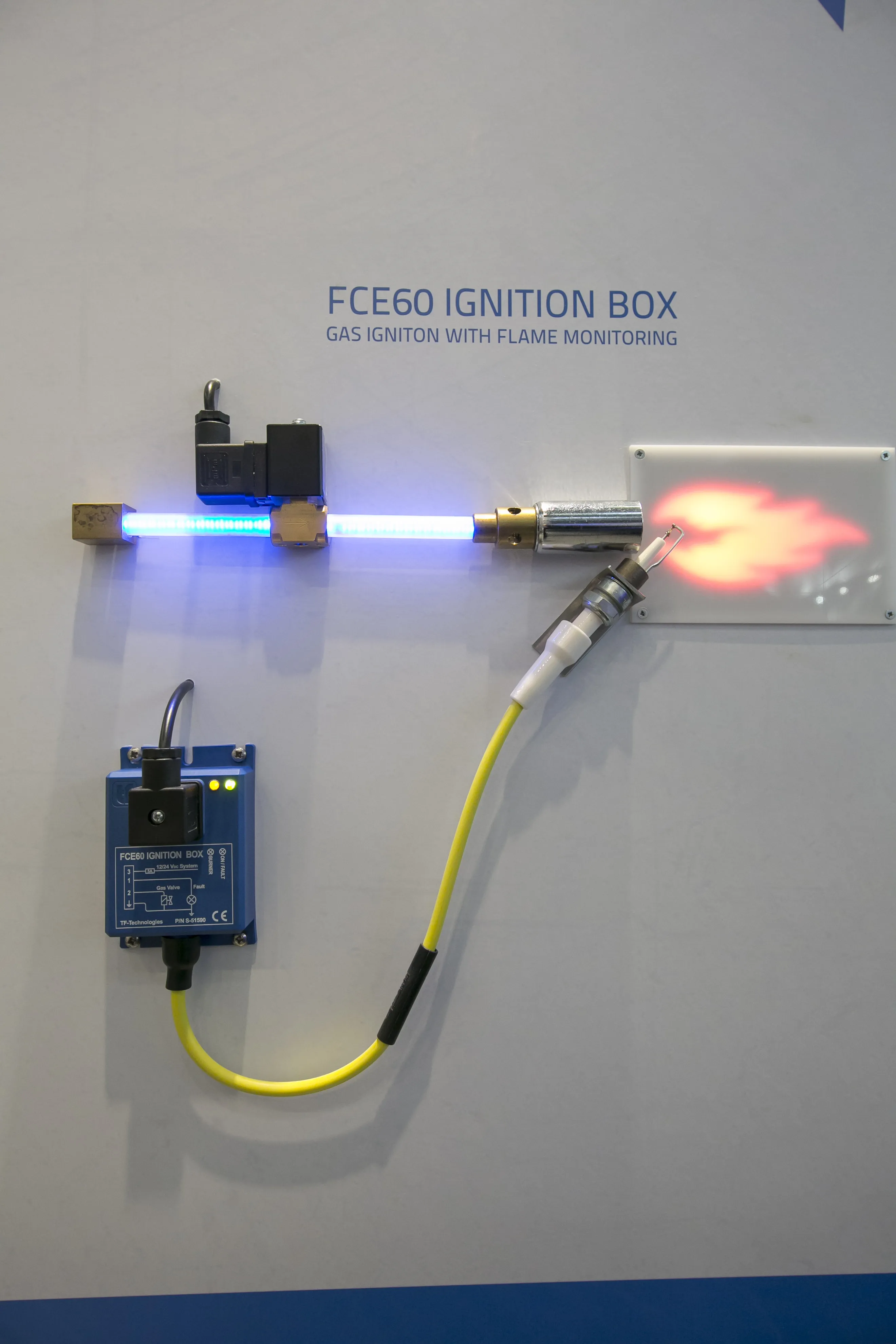

Danish firm TF-Technologies has created a new ignition box for gas burner systems, the FCE60: the only one on the market to comply with EU safety regulation EN 298: 2012 Automatic burner control systems for burners and appliances

“We invented the original version of the ignition box 25 years ago and since then it has been copied by many people” said TF-Technologies CEO Lisbeth Teilmann. “We were getting feedback from the market asking whether our ignition boxes complied with this standard which caused us

April 19, 2016

Read time: 2 mins

Danish firm 8410 TF-Technologies has created a new ignition box for gas burner systems, the FCE60: the only one on the market to comply with EU safety regulation EN 298: 2012 Automatic burner control systems for burners and appliances

“We invented the original version of the ignition box 25 years ago and since then it has been copied by many people” said TF-Technologies CEO Lisbeth Teilmann. “We were getting feedback from the market asking whether our ignition boxes complied with this standard which caused us to investigate.”

In accordance with the latest version of EN 298, which took over from its predecessor in May 2015, TF-Technologies’ new ignition box has a lot of built in redundancies with four times as many components and three control circuits. The system works by monitoring whether there is a flame; if there isn’t, it attempts to ignite the gas and if that fails, it switches off the gas supply, preventing accidents. For the previous model, if one component failed, the whole protection system could potentially fail.

TF-Technologies originally invented the ignition box for road pavers, although many of these have now switched over to electrical systems from gas. The boxes are also supplied to asphalt containers, crack sealing machines and hot boxes.

All videos

“We invented the original version of the ignition box 25 years ago and since then it has been copied by many people” said TF-Technologies CEO Lisbeth Teilmann. “We were getting feedback from the market asking whether our ignition boxes complied with this standard which caused us to investigate.”

In accordance with the latest version of EN 298, which took over from its predecessor in May 2015, TF-Technologies’ new ignition box has a lot of built in redundancies with four times as many components and three control circuits. The system works by monitoring whether there is a flame; if there isn’t, it attempts to ignite the gas and if that fails, it switches off the gas supply, preventing accidents. For the previous model, if one component failed, the whole protection system could potentially fail.

TF-Technologies originally invented the ignition box for road pavers, although many of these have now switched over to electrical systems from gas. The boxes are also supplied to asphalt containers, crack sealing machines and hot boxes.

All videos