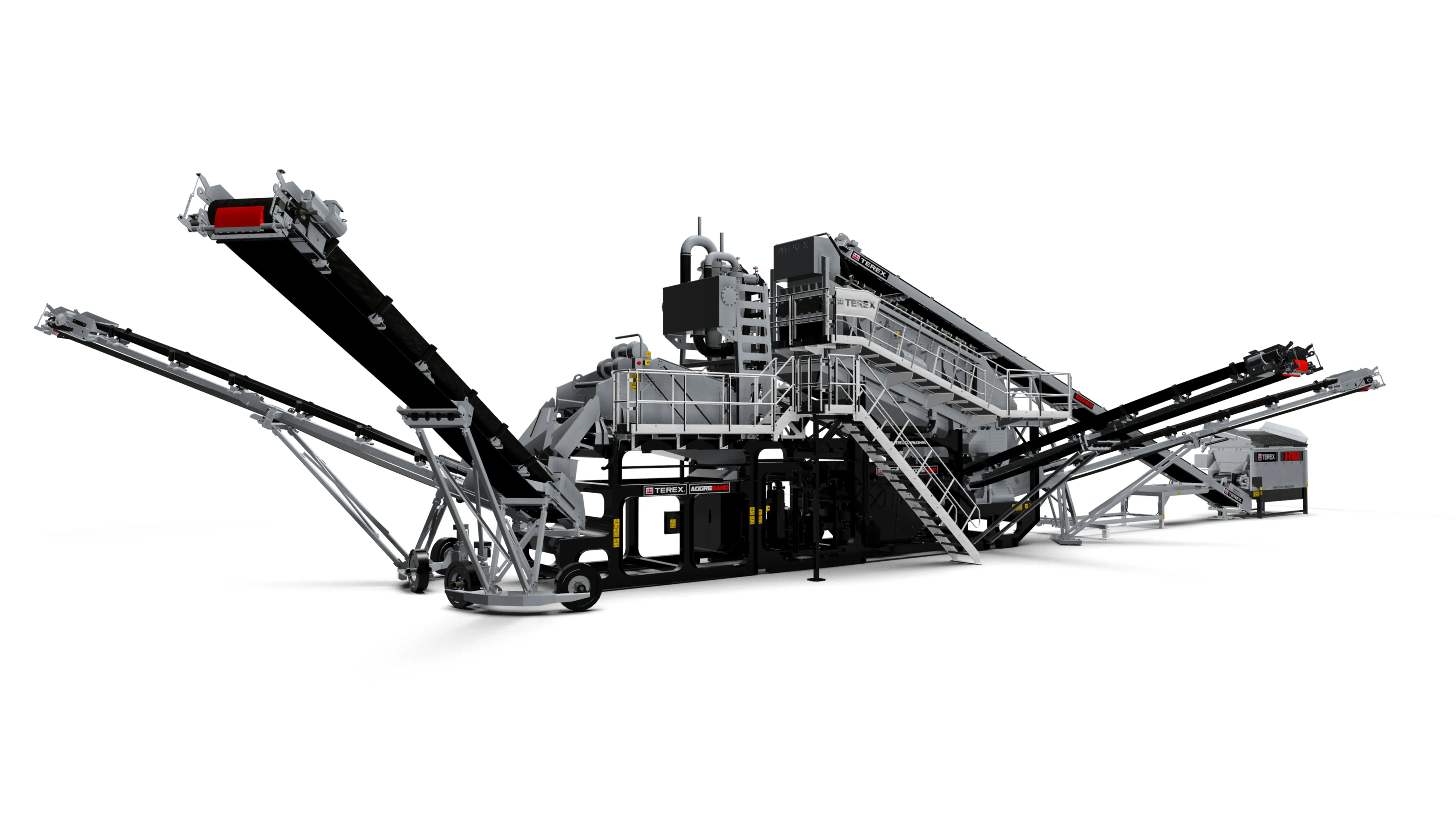

Terex Finlay’s new I-140 direct drive ø1,270mm x 1,240mm horizontal impact crusher offers variable speed for production in recycling, mining and quarrying applications.

A significant engineering approach being introduced in this model is the material flow through the plant. The flow of material has been significantly improved by increasing the width of components as the material moves through the machine, says Terex Finlay.

The I-140’s robust and proven Terex CR032 chamber is said to give excellent

March 11, 2016

Read time: 2 mins

A significant engineering approach being introduced in this model is the material flow through the plant. The flow of material has been significantly improved by increasing the width of components as the material moves through the machine, says Terex Finlay.

The I-140’s robust and proven Terex CR032 chamber is said to give excellent reduction ratios and high consistency of product shape.

The machine features an advanced electronic control system that monitors and controls the speed of the rotor and regulates the heavy-duty vibrating feeder with integrated pre-screen to maintain a consistent feed of material into the impact chamber for optimal crushing conditions.

Material from the integrated pre-screen can be diverted to a stock pile via the optional by-pass conveyor, or it may join the crushed product on the main belt. The standard hopper capacity is 6m³.

“The introduction of the Terex Finlay I-140 represents a significant step change in our family of impact crushers. Our field test results of extensive testing have recorded significant productivity increases depending on the application, over the model that it replaces,” says Alan Witherow, product manager.

“The enhanced material flow process of the plant represents a significant step change to our engineering ethos and in due course will be extended to encompass our range of impact crushers.

A fully hydraulic apron setting assist provides convenient and efficient adjustment of the aprons while an optional under crusher vibratory plate feeder with wear resistant liners aids material discharge flow.