The driver for WITOS is the growing trend for client and contractor to document, in real time, the progress of paving projects. WITOS does this by bringing together the different players on the project - from construction managers to asphalt plant operators and truck drivers. The system ensures greater transparency across the entire paving process.

WITOS Paving, for example, can document how many trucks are approaching the job site and so allow the onsite team time to get ready for their arrival. As such, the pave speed can remain constant - which in turn improves paving quality.

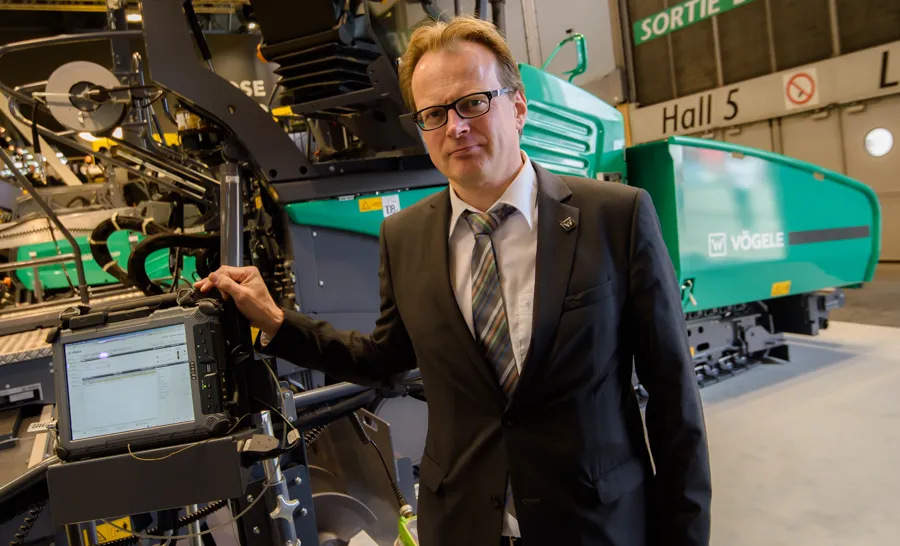

One of the benefits of WITOS Paving is its integration into the ErgoPlus 3 operating system. This allows paver operators to receive a constant flow of information on their console display about incoming mix lorries and the current progress of construction - all without a separate display. All the requisite information is displayed directly in the paver operator's field of vision.

WITOS Paving has five function modules: control, materials, transport, jobsite and analysis.

WITOS Paving Control, for instance, supports simple project planning by means of an assistant that guides the construction manager through all the parameters relevant for planning, step by step. The control module calculates the required quantity of mix as a function of the length and width and the variable geometries of the proposed construction project.

The number of lorries required to supply mix to the paver is passed on to the materials module. The system suggests a variable working cycle to the asphalt mixing plant supervisor, and this cycle is continually aligned with the frequently varying capacities of the lorries. In many cases, that also allows the number of lorries required to be reduced, Voegele says.