Wirtgen is now offering a novel cold milling concept in the shape of its innovative W 200 Hi model. This large milling machine features a hydraulically driven milling drum assembly that can be displaced 400mm to both the right and the left, ensuring maximum versatility on the job. This machine has been developed to meet the needs of contractors having to work in the confined conditions encountered in urban traffic and on highway sites with flowing traffic. The moveable drum allows this large planer to carry

January 29, 2014

Read time: 2 mins

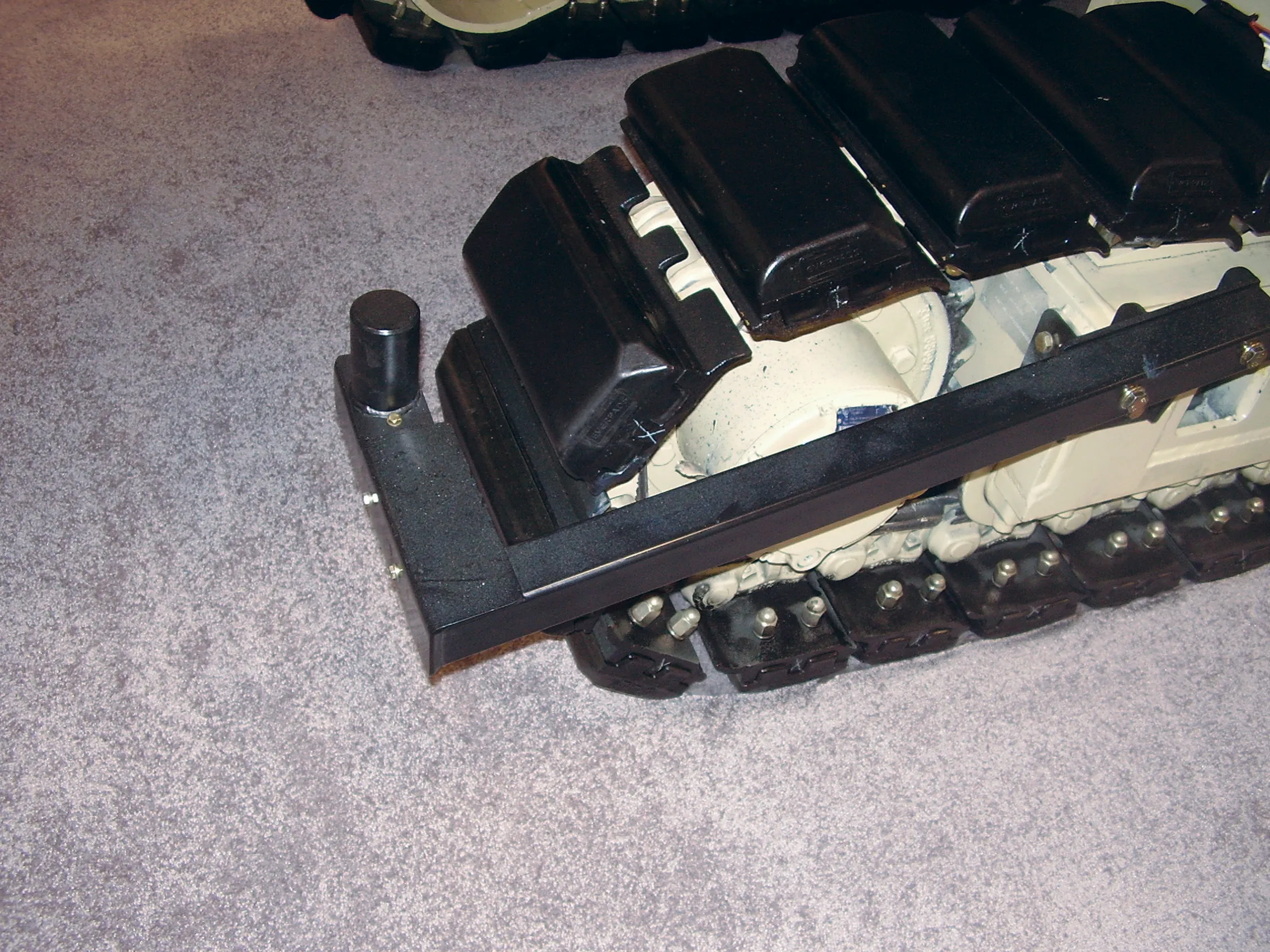

The hydraulically driven milling drum assembly can be displaced by up to 800mm, allowing the W 200 Hi to work around obstacles as water inlets and street lamps. The milling drum assembly can also be displaced while in operation and gives the cold milling machine a zero edge on both sides. The same machine can also be used to work flush with kerbstones or concrete barriers both on the right and left side, allowing trucks carrying materials and from the site to move in and out of the traffic stream.

The versatility allows the W 200 Hi to be used in urban road construction and repair operations, with the moveable drum assembly reducing the milling radii. Its edge protector can also be raised by up to 420mm allowing the machine to work flush with the edge.

Power for the W 200 Hi comes from a 433kW diesel, while the machine features the firm’s sensor-controlled LEVEL PRO automatic level control, the parallel to surface control to ensure accurate working depth and the intelligent speed control of the track drives for optimum traction. Meanwhile the vacuum cutting system and low emissions exhaust technology help to minimise its environmental profile. The machine offers a cutting width of 2.1m and a working depth down to 300mm. Other features include good all round visibility and CCTV equipment for safety.

www.Wirtgen.de