With an operating weight of around 28.4 tonnes and with a 4x9 Kelly bar, the SR-30 Eagle can be easily transported to other jobsites without having to disassemble the excavation equipment.

A heavy-duty undercarriage and a counterweight of 3,250kg allow the Eagle to feature an agile turret with a tail swing radius of 3,335mm. As well, it can use the latest generation Soilmec Segmental Mast, designed to easily switch to the LHR (low head room) and CFA (continuous flight auger) configurations. The result is a physical compactness and excellent torsional strength.

This solution enables an outstanding technological performance. In its LDP (large diameter piling) configuration, it is possible to install up to 5x9 self-mounting Kelly bar or non self-mounting 10.5m-long bars with five elements at an excavation depth of 47.5m. The LHR configuration has a minimum height of 7.4m and can move 5x4 Kelly bars, while the CFA configuration offers a mast extension for a maximum drilling depth of 22m.

The strength of the mast has made it possible to install a rotary with a maximum torque of 131kNm, capable of optimising torque and rotation speed during excavation, thanks to the automatic control of motor displacement. The rotary is provided with a new hydraulic block that has been redesigned for more efficient hydraulic performance to reduce consumption.

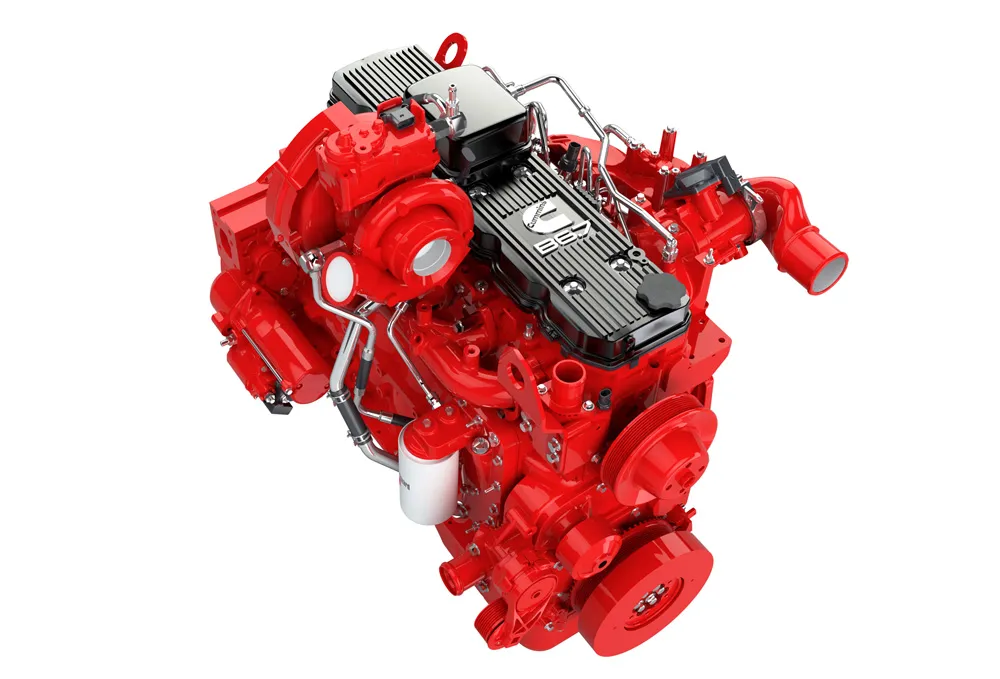

To better support the rotary performance, the turret has been equipped with the latest generation StageV/Tier4f diesel engine equipped with low-idle to improve fuel efficiency and decrease noise pollution. The 4.5litre four-cylinder Cummins engine delivers a maximum power of 149kW.

Among standard equipment on the SR-30 Eagle are the camera system with monitor in the cabin and radio control for loading and unloading operations. There is also an automatic return-to-the-centre-hole system and an anti-slack rope system and the load cell on the main winch for the Kelly bar version.

In short, the SR-30 Eagle is perfect for working in residential areas and confined spaces and easily moved to the next tight job site in a very short time.