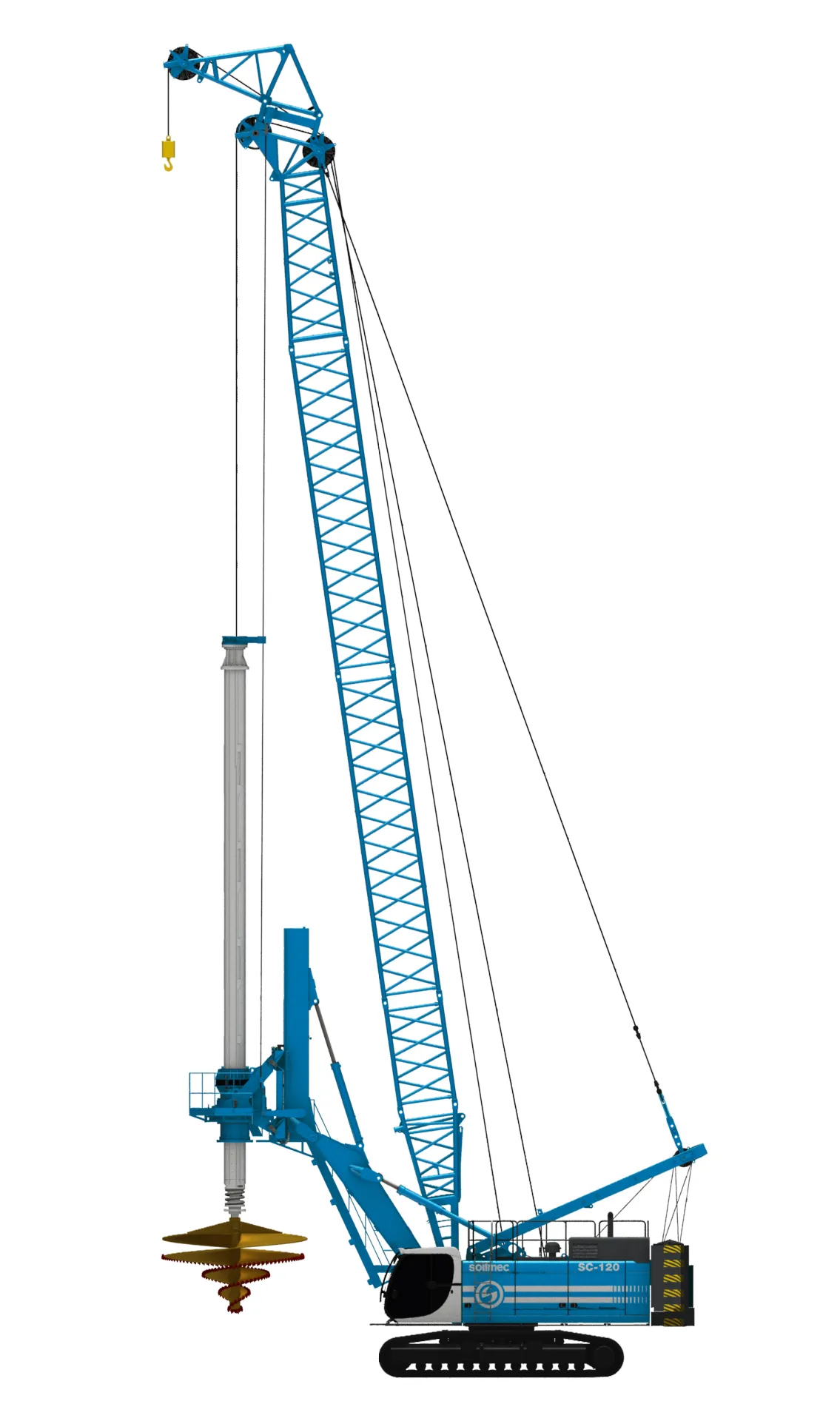

Soilmec is completing its range of heavy-duty cranes with the introduction of the powerful SC-50 HD and SC-120 HD models. With the addition of these two cranes the range now comprises the SC-50, SC-70, SC-80, SC-90, SC-120 and SC-135 models. As with the existing machines the two new cranes are designed for use in tough working conditions and for applications such as diaphragm wall grabbing, hydraulic rotary boring, pile driving, dragline work, clamshell duties or dynamic compaction for example.

January 6, 2017

Read time: 2 mins

The models are fitted with Soilmec’s new H-cab, which features good all round visibility and high operator comfort. A key feature for the operator is the sophisticated touchscreen DMS package, which monitors working functions and parameters. This system allows full monitoring, recording and analysis of operation, with dedicated software providing full data handling and storage capabilities. Customers can specify the SC machines with either Tier 4 Fina/StageIV compliant diesels or Tier 3/Stage IIIA engines, depending on the location where the units will be used.