Sooner rather than later, regulations will address bucket dropping. And when the inevitable happens, SMP Parts AB and its customers will be prepared. “There will be some regulation,” said Charlie Svantesson, area sales with SMP Parts. “This product is in response to those (likely) regulations.” The product Svantesson refers to is the SMP HardLock Quick Coupler, based on the reversible “S” models.

The coupler features a standard rear-locking at the back and a centre locking that secures the front axle. Th

January 6, 2017

Read time: 1 min

Sooner rather than later, regulations will address bucket dropping. And when the inevitable happens, 8019 SMP Parts AB and its customers will be prepared.

“There will be some regulation,” said Charlie Svantesson, area sales with SMP Parts. “This product is in response to those (likely) regulations.”

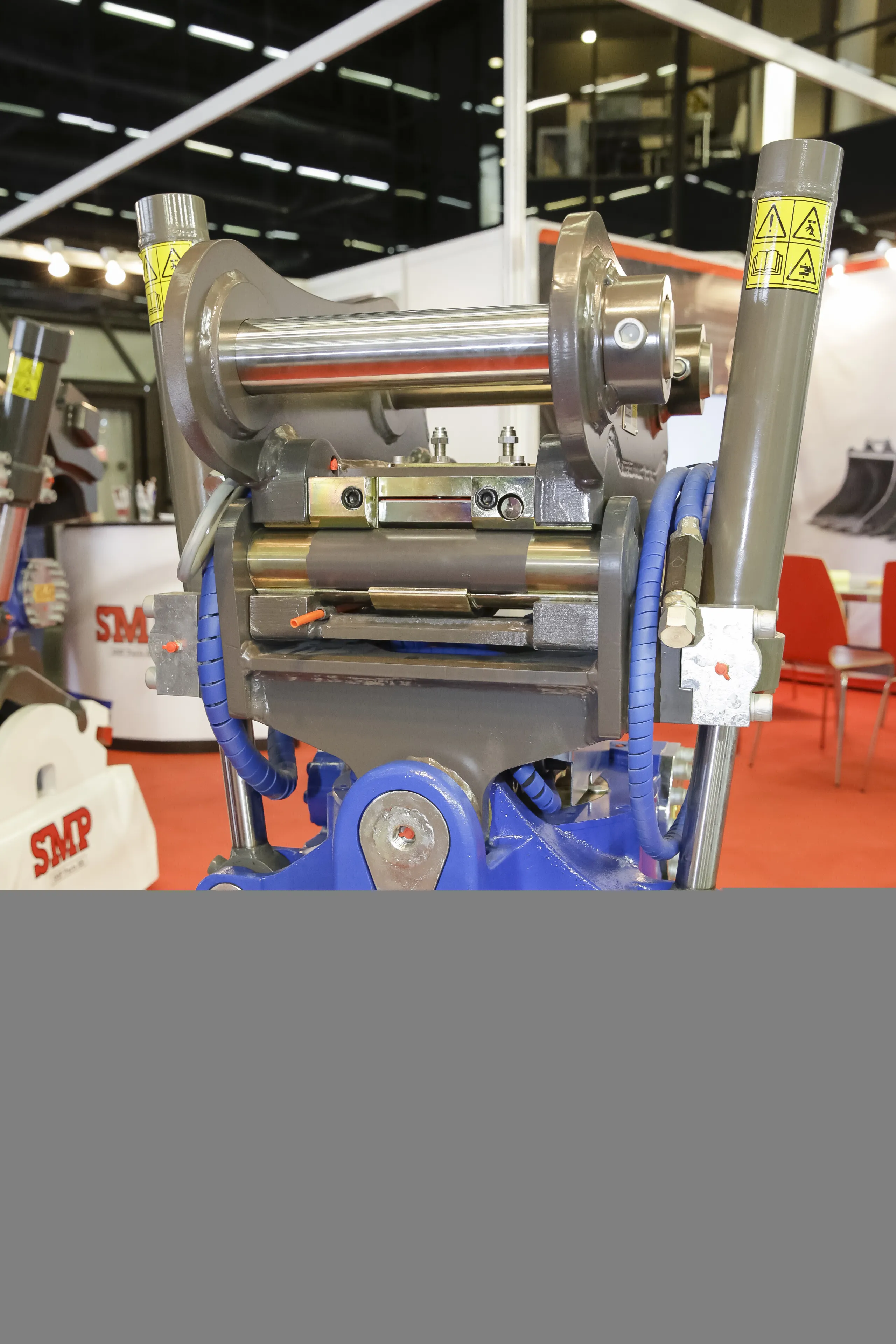

The product Svantesson refers to is the SMP HardLock Quick Coupler, based on the reversible “S” models.

The coupler features a standard rear-locking at the back and a centre locking that secures the front axle. The system ensures “zero play” and a safe connection for tools and attachments.

The locks, combined with consistent hydraulic pressure, make the difference, Svantesson said.

“You can’t drop your bucket,” Svantesson said. “That’s the main benefit.”

The couplers fit machines with weights that vary from 5-40tonnes. There are five coupler models, ranging from 85-320 kg.

“There will be some regulation,” said Charlie Svantesson, area sales with SMP Parts. “This product is in response to those (likely) regulations.”

The product Svantesson refers to is the SMP HardLock Quick Coupler, based on the reversible “S” models.

The coupler features a standard rear-locking at the back and a centre locking that secures the front axle. The system ensures “zero play” and a safe connection for tools and attachments.

The locks, combined with consistent hydraulic pressure, make the difference, Svantesson said.

“You can’t drop your bucket,” Svantesson said. “That’s the main benefit.”

The couplers fit machines with weights that vary from 5-40tonnes. There are five coupler models, ranging from 85-320 kg.