SmoothRide is a vehicle-mounted resurfacing solution for paving and milling projects. It uses a combination of core Topcon technologies designed to deliver the smoothest surface possible, while efficiently managing the quantity of material for each project.

With the new RD-M1 scanning unit, the system maps the existing surface elevations - with many more points captured versus what can be expected with traditional tools. This provides more accurate data needed to confidently estimate materials, as well as to form the basis of the final design surface.

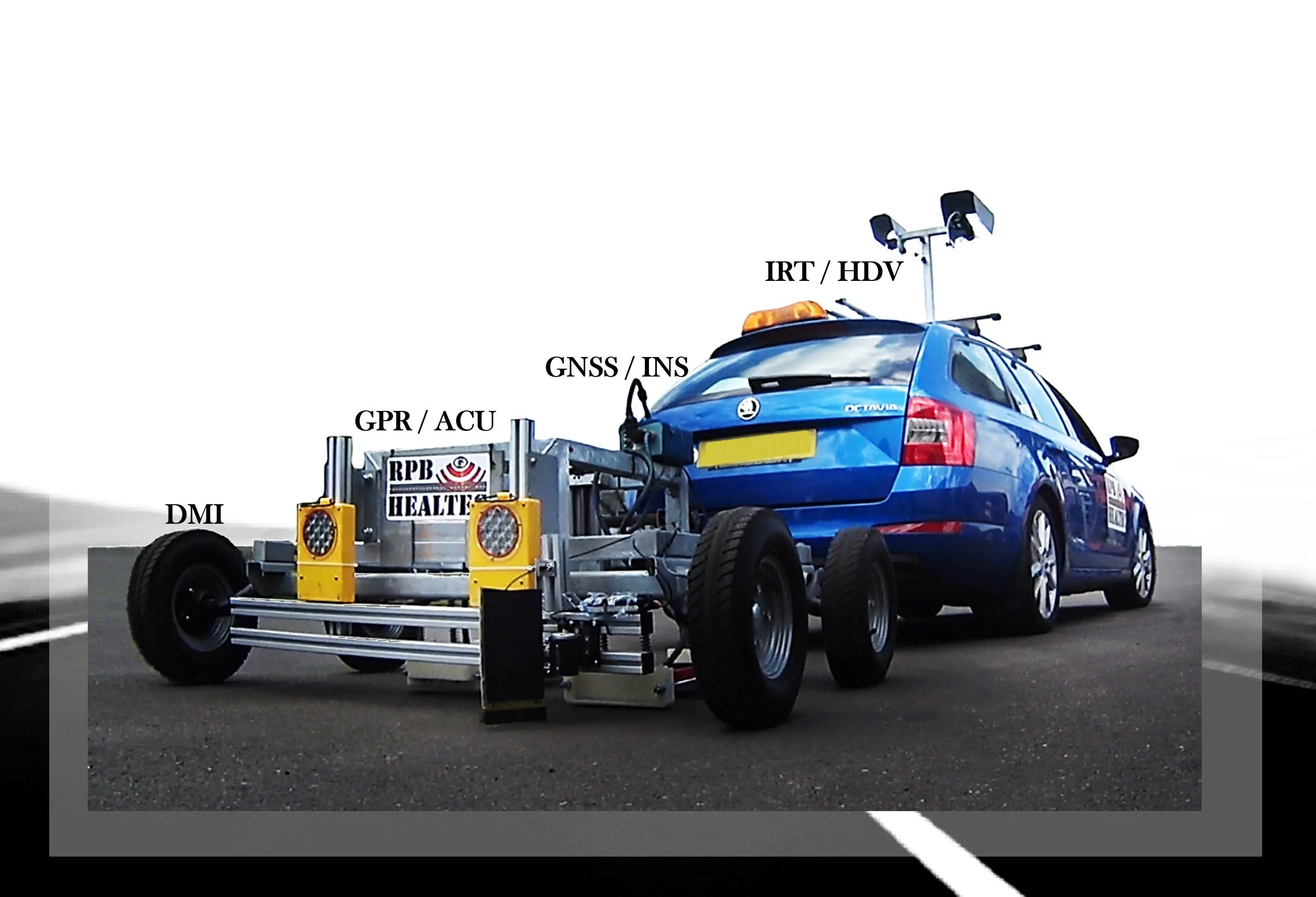

The workflow consists of a vehicle-mounted road scan, existing and finish surface design, and machine control using GNSS with sonic tracker sensor guidance.

Once the road information is gathered, operators can use Mobile Master Office point data processing software to recreate the existing surface. Magnet Office with Resurfacing is then used to digitally create a high-resolution model of the required finished mat.

The resurfacing module allows operators to create a design using specific regulatory requirements such as minimum thickness, desired cross-slope, and overall smoothness.

The information is then passed onto a paver or milling machine to allow for variable depth paving to where it is required - with the result being a much smoother road as well as faster completion times, explained Jörg Velten, Topcon Construction’s European support manager.