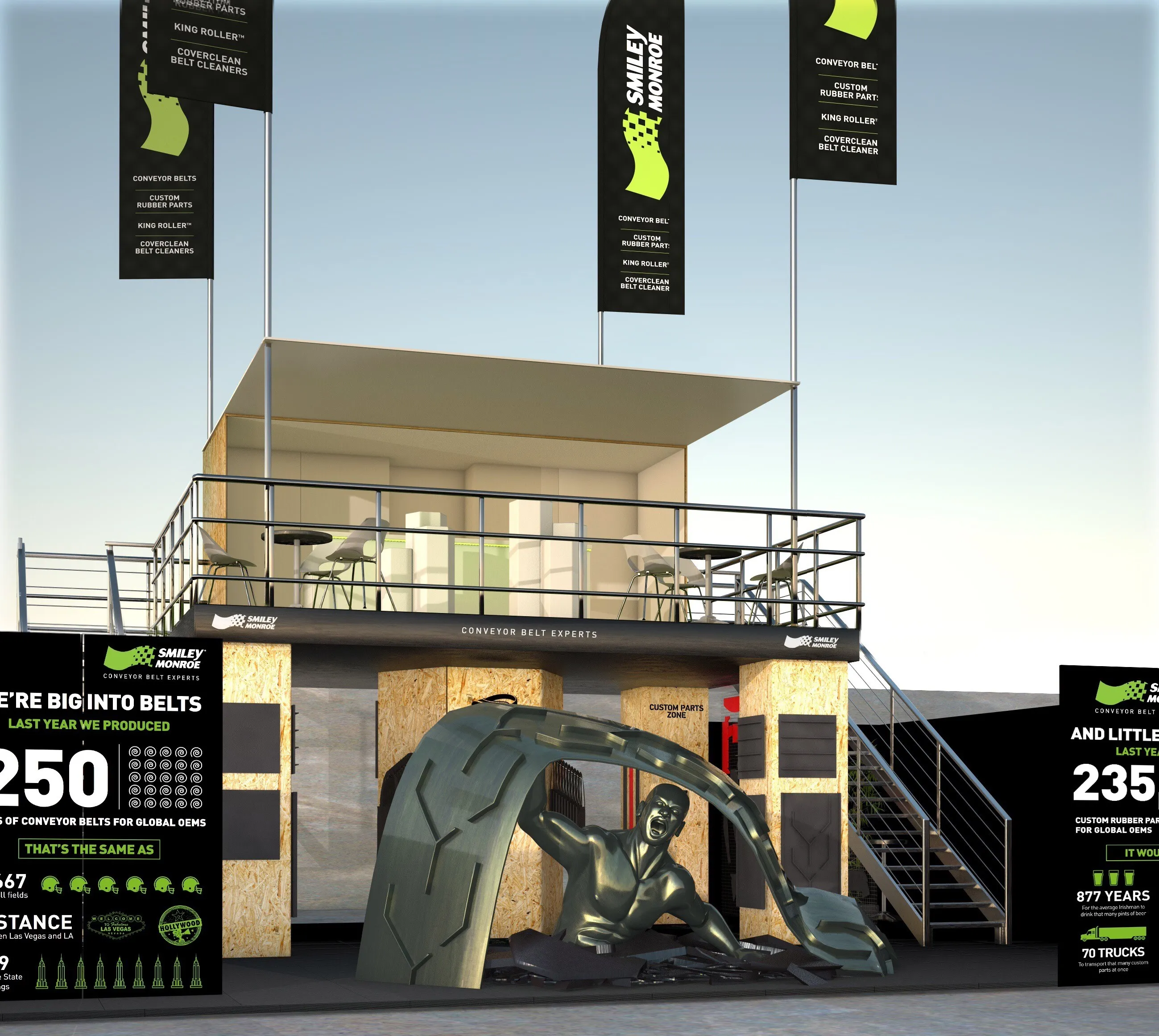

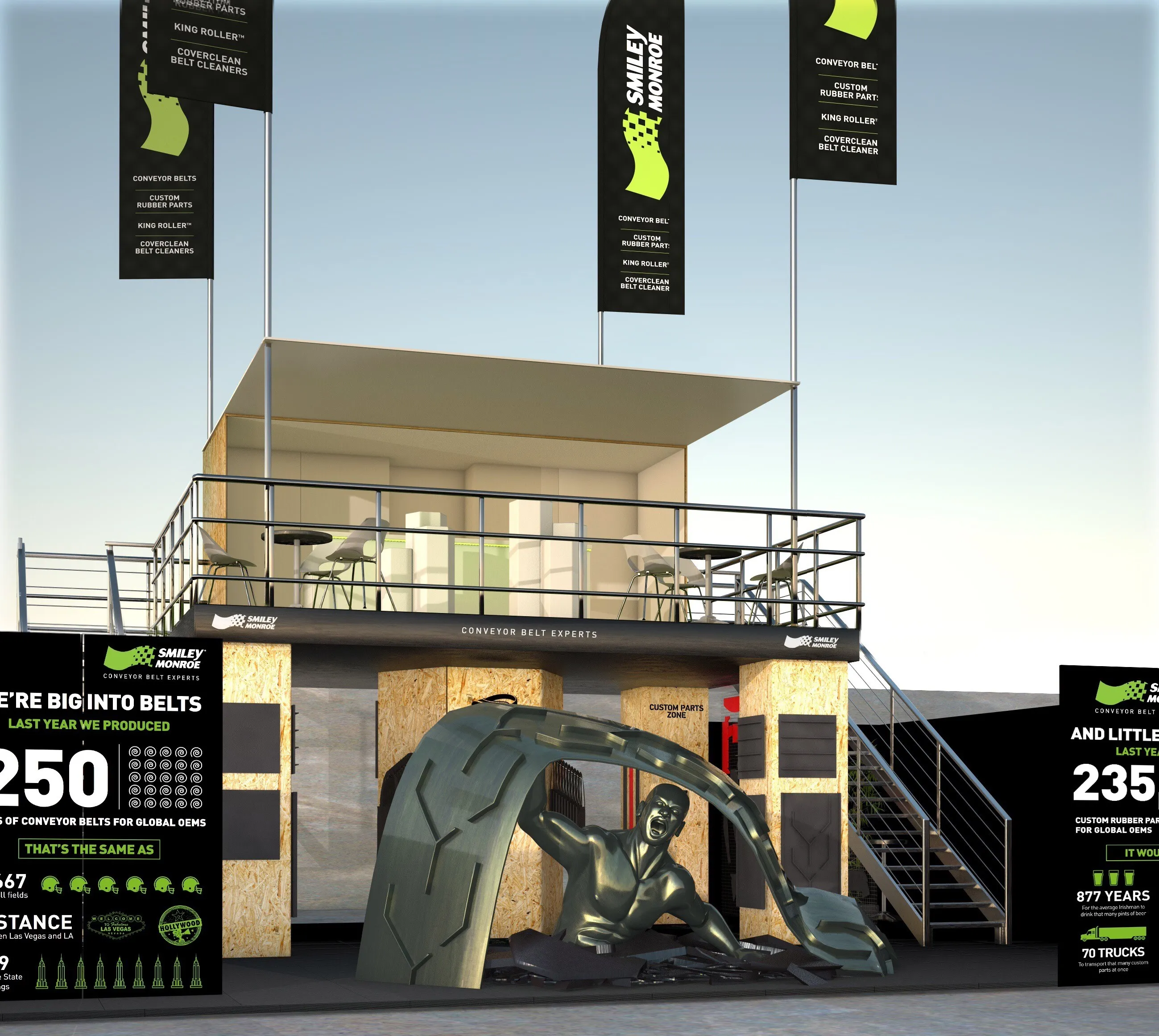

8409 Smiley Monroe is introducing its latest technology for endless conveyor belts and custom rubber parts to the North America market. The firm is keen to further develop its market presence in North America, where the company is growing its exports to OEM customers in the mobile equipment sector. The firm has developed innovative solutions for conveyor belt systems that offer high productivity and low maintenance needs in an array of tough industry applications. The firm also offers custom rubber parts for its clients that are made to high quality standards and which offer long working life according to the firm. The tried and tested systems can be utilised in an array of crushing, screening, washing and recycling machines. In addition to producing conveyor belts and custom rubber parts for its customers in the materials production and classification markets, Smiley Monroe has also started supplying the environmental and road construction sectors with special belts. The firm invested in new equipment and processes to customise endless belts by adding features such as hot moulded rubber cleats, side rails and side walls to the carrying surface, to suit a customer’s specific application. And new high pressure presses allow Smiley Monroe to manufacture heavy duty rubber wear liners for hoppers.