Following the introduction of

Using low energy Bluetooth, the cap monitors engine hours through vibration frequencies, and feeds operational data directly to the app when the user’s smartphone is within Bluetooth range of the engine. It simultaneously gathers GPS data from the smart phone, providing a low-cost basic tracking function.

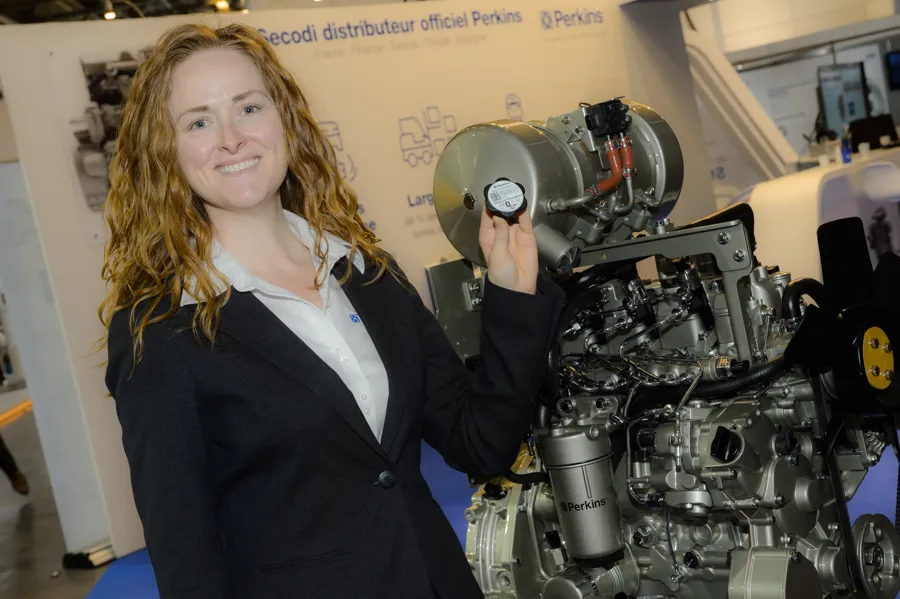

“SmartCap complements the MyEngine app and the two elements can calculate predicted service times and provide a list of consumables and service criteria for that engine,” said Siobhan Scott, marketing manager for Perkins’ aftermarket division.

The electronic oil filler cap costs £39.99, and any registered MyEngine app user will be able to read the electronic oil cap data of any Perkins engine equipped with the cap – useful for those buying second-hand Perkins-powered equipment. The SmartCap has an expected working life of two to three years, after which a replacement cap will need to be purchased.

The app and cap have also won a prestigious Edison Award for innovation.