Oevermann, a German construction company, has been seeking to improve its use of digital solutions across sites to cut costs and boost productivity. Based in Meschenich, Cologne, one of Oevermann’s most recent projects was to deliver a core new transport system - the B51N. This road route was built to improve safety and reduce the amount of traffic for local residents.

Oevermann needed to consider the impact of its work across the countryside, with daily deliveries between 500㎥ and 900㎥ of fill material arriving at the site for distribution by the team.

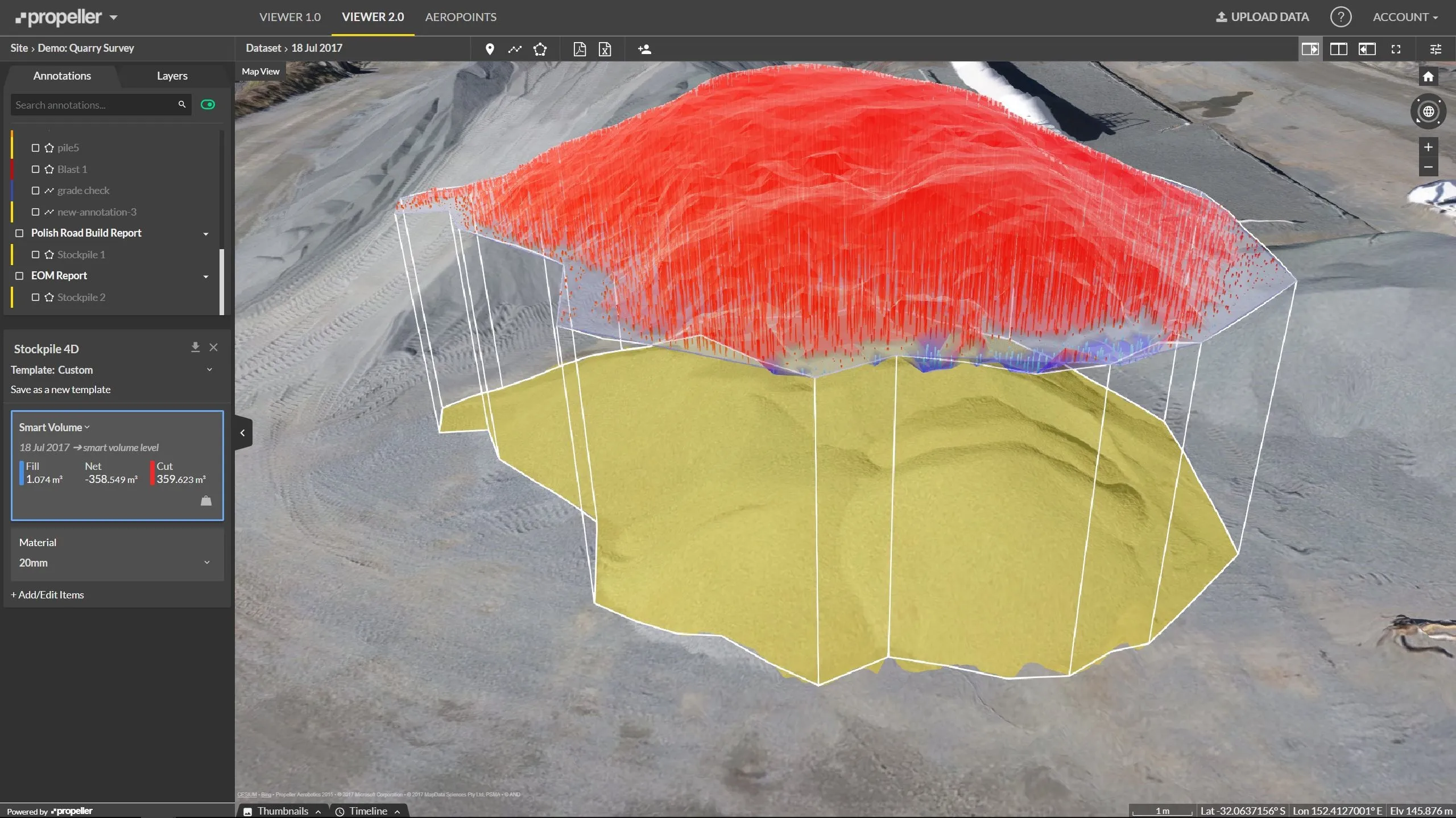

By utilising the Dashboard functionality from Komatsu Smart Construction, the Oevermann team was able to assess the amount of material being pushed by the fleet into position, while filling the cut space through the collection of as-built data that was used to create a digital twin.

The collected as-built data was also able to differentiate between the materials being used on site, enabling the site managers to have full tracking capability of the supply throughout construction. Through the use of Dashboard, contractors could also analyse the cost of the cut and fill process, allowing teams to ensure quoting and budgeting was accurate, improving profitability informed by data.

A digital twin also offers the site manager the ability to compare the most recent as-built terrain surface with the intended design file, making it easier to understand how far the project has progressed.

In the case of the construction of the B51N, the Oevermann team was able to unlock a system that managed staff requirements on site more efficiently and informed the team that a smaller dozer was required to move materials, reducing costs.

Surveying costs were largely eliminated as drone data enabled teams to avoid the need for surveyors to monitor the site, providing extensive savings over the 18-month project.