Conveyors in mines, quarries and cement plants perform a tough job in harsh conditions: mineral extraction and processing creates large amounts of highly abrasive dust that can enter into machinery; mix with the lubricant inside, and cause accelerated wear and eventual failure of bearings, seals, gears, couplings and other rotating parts.

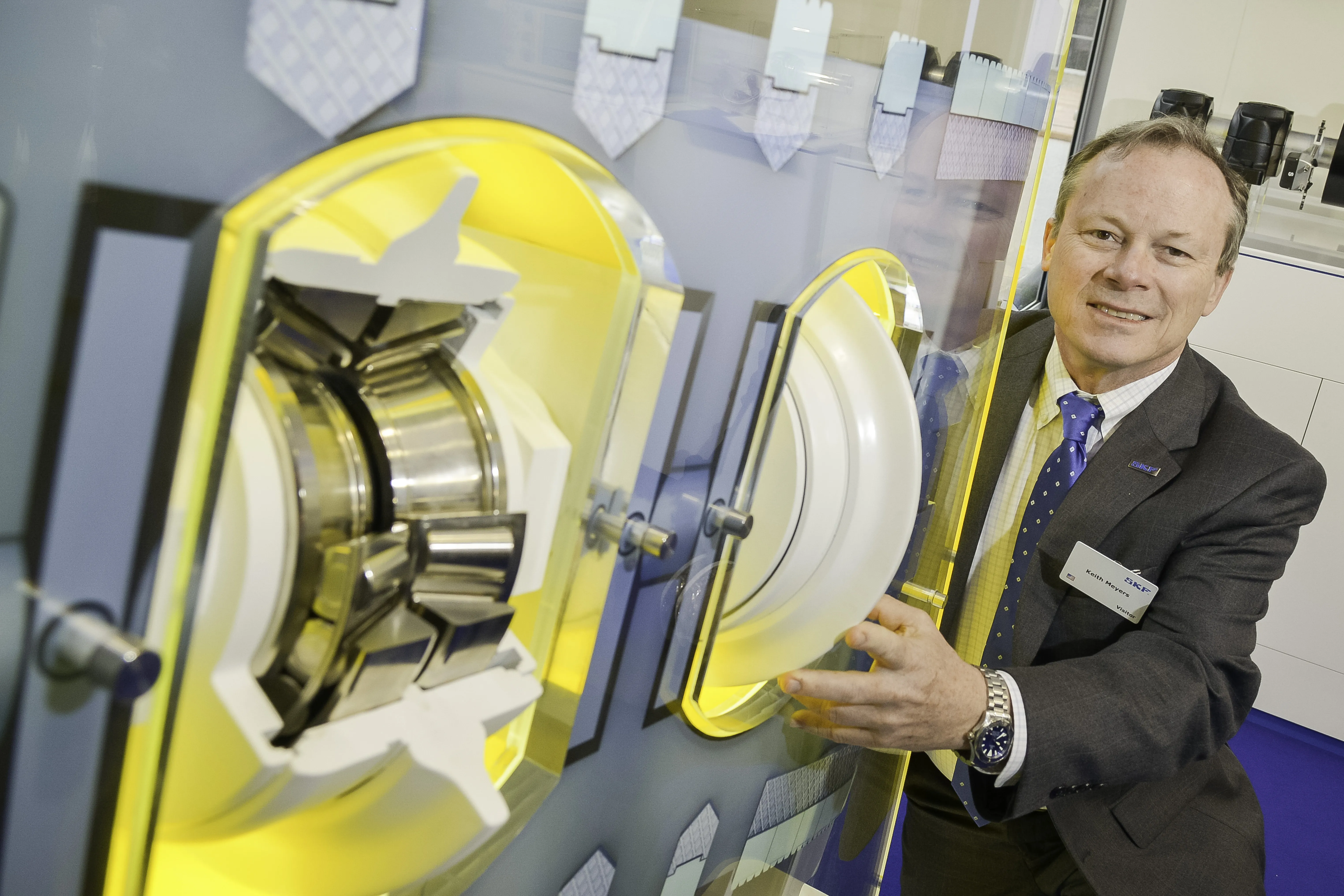

SKF design solutions for conveyors, include the SKF Three-barrier solution, housings; sealed SKF Explorer spherical roller bearings, and the new SKF Taconite seal.

The SKF Three-barrier solution is said to be an environmentally-friendly, cost-effective solution that is proven to extend service life of the conveyor pulleys. The solution provides the conveyor bearing with three layers of protection against contamination and greatly reduces the amount of lubrication required by up to 90%.

For extreme contaminated conditions, the SKF Three-barrier solution is combined with the new SKF Taconite seal to block contamination entering the housing, including high pressure water during maintenance.

“The conveyor products are just a small sample of our wide variety of solutions and services for the mining belt conveyor,” says Keith Meyers, SKF’s global industry manager mining, mineral processing and cement.

“Our aim is to help our customers build reliability into their products from the outset, and support their operations and maintenance activities in a way that minimises downtime and cuts total cost of ownership.”