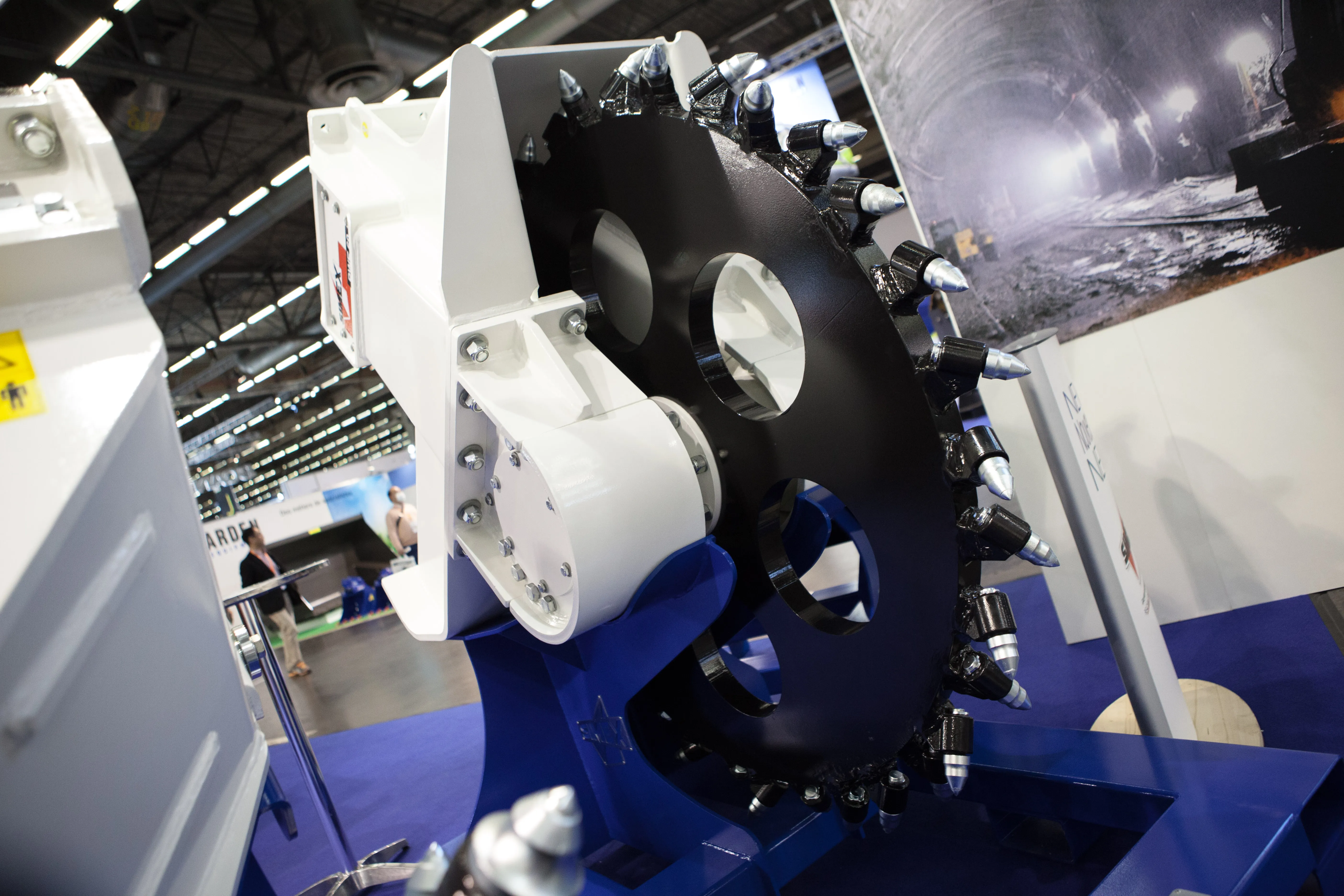

Specialist firm Simex has unveiled five new attachments at Intermat 2015. “The only way to improve the company and to maintain our market share is to keep producing new products,” said sales manager Alessandro Sola. “The business is based on patented attachments: we try to lead the way in our market.”

The latest raft of attachments comprises the RW 500, a self-levelling wheel saw for front loaders; the RWE 60, a wheel saw for an excavator boom; the CB 1500, a crusher bucket for front loaders; the MP 1000,

January 6, 2017

Read time: 2 mins

Specialist firm 1141 Simex has unveiled five new attachments at Intermat 2015. “The only way to improve the company and to maintain our market share is to keep producing new products,” said sales manager Alessandro Sola. “The business is based on patented attachments: we try to lead the way in our market.”

The latest raft of attachments comprises the RW 500, a self-levelling wheel saw for front loaders; the RWE 60, a wheel saw for an excavator boom; the CB 1500, a crusher bucket for front loaders; the MP 1000, a cutter head for profiling tunnels; and the VSE 30, a screening bucket for smaller excavators which allows the size of material to be varied from inside the cab.

Wheel saws are popular, said Sola, since they are used to create trenches for laying cables and fibre optics. The RW 500 uses Simex’s patented self-levelling technology, developed for its planers, to ensure that the trench is level, whatever the slope of the ground surface.

The wheel saw for excavators can be used on machines between 20 and 45 tonnes. “This will be very good for the Northern European markets,” predicted Sola. “Because many dealers there have excavators rather than skid loaders.”

The VSE 30 joins Simex’s VSE 40 screening bucket, the prototype of which was shown for the first time two years ago. The VSE 30 has been designed for machines between 16 and 28 tonnes, whereas the VSE 40 is for 24- to 40-tonne excavators.

The latest raft of attachments comprises the RW 500, a self-levelling wheel saw for front loaders; the RWE 60, a wheel saw for an excavator boom; the CB 1500, a crusher bucket for front loaders; the MP 1000, a cutter head for profiling tunnels; and the VSE 30, a screening bucket for smaller excavators which allows the size of material to be varied from inside the cab.

Wheel saws are popular, said Sola, since they are used to create trenches for laying cables and fibre optics. The RW 500 uses Simex’s patented self-levelling technology, developed for its planers, to ensure that the trench is level, whatever the slope of the ground surface.

The wheel saw for excavators can be used on machines between 20 and 45 tonnes. “This will be very good for the Northern European markets,” predicted Sola. “Because many dealers there have excavators rather than skid loaders.”

The VSE 30 joins Simex’s VSE 40 screening bucket, the prototype of which was shown for the first time two years ago. The VSE 30 has been designed for machines between 16 and 28 tonnes, whereas the VSE 40 is for 24- to 40-tonne excavators.