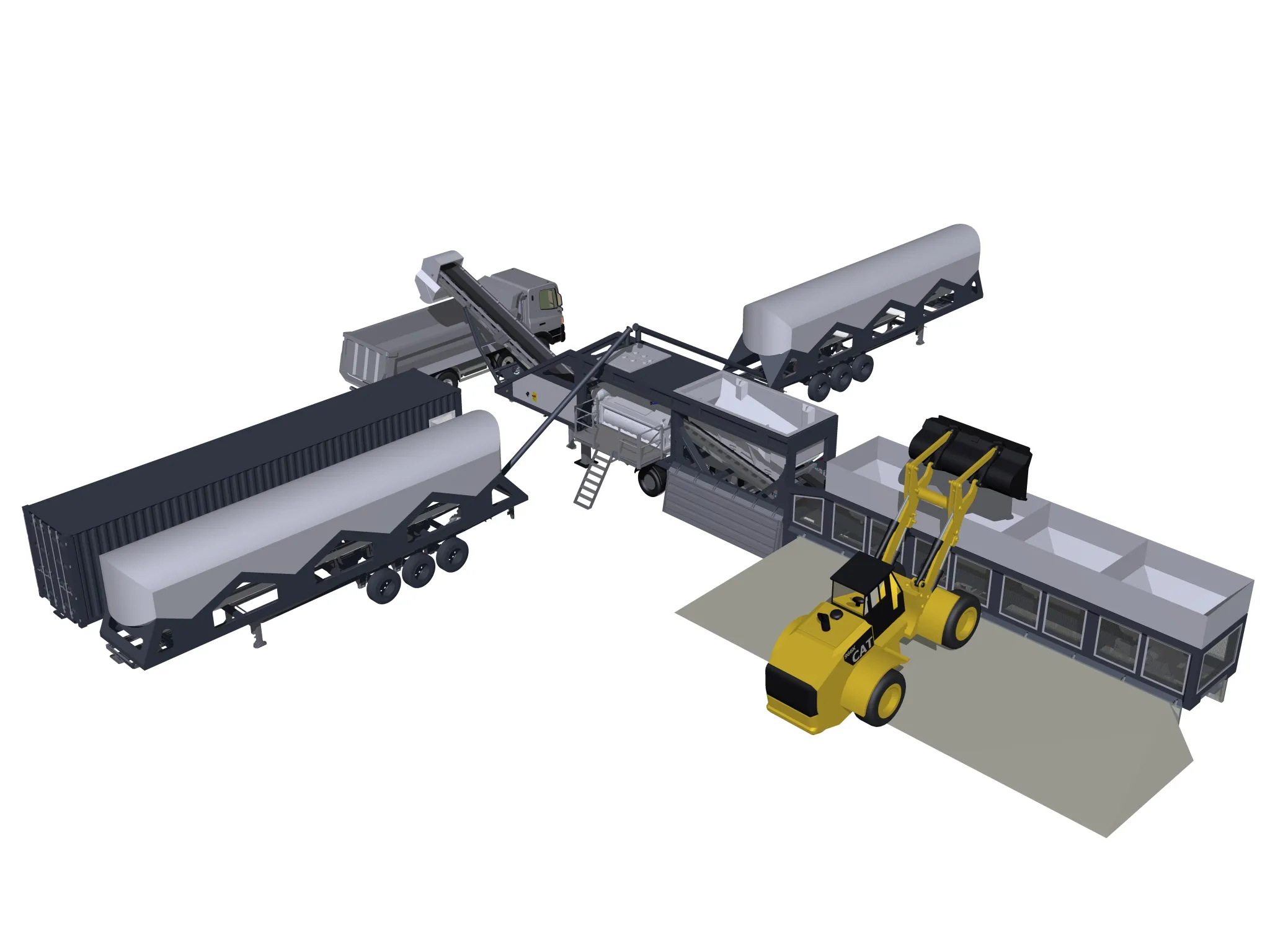

SIMEM says that its innovative BISON concrete plant is both versatile and mobile. The new continuous mixing plant can be used for an array of duties such as for supplying road base material, for supplying RCC applications and for soil treatment. The firm claims that the plant offers a large output capacity combined with a capability for producing output with a very high accuracy of specification. Because the plant is trailer-mounted, it is highly mobile and can be moved quickly from site to site while commi

January 6, 2017

Read time: 2 mins

The firm says that the plant is versatile and can be fitted with a range of extra features as options. A trailer-mounted control cabin and service container are available, as is additional aggregates storage, a 40m3 capacity dosing trailer and a trailer-mounted cement silo with a capacity of 55m3.