German firm Sennebogen is introducing the 6113 telescopic crawler crane and the new 640 HD duty cycle crawler crane. The 6113 is the manufacturer’s biggest telescopic crawler crane yet. It offers “a safe working load of 120tonnes, a proven boom concept, and a high level of flexibility,” says the company. The machine has extended the maximum safe working load of Sennebogen’s telescopic crane range by more than 50%. “Thanks to multi-cylinder technology, this maintenance-free boom system enables continuous tel

February 19, 2015

Read time: 2 mins

German firm 2924 Sennebogen is introducing the 6113 telescopic crawler crane and the new 640 HD duty cycle crawler crane. The 6113 is the manufacturer’s biggest telescopic crawler crane yet.

It offers “a safe working load of 120tonnes, a proven boom concept, and a high level of flexibility,” says the company. The machine has extended the maximum safe working load of Sennebogen’s telescopic crane range by more than 50%. “Thanks to multi-cylinder technology, this maintenance-free boom system enables continuous telescoping and is always friction-locked,” says Sennebogen.

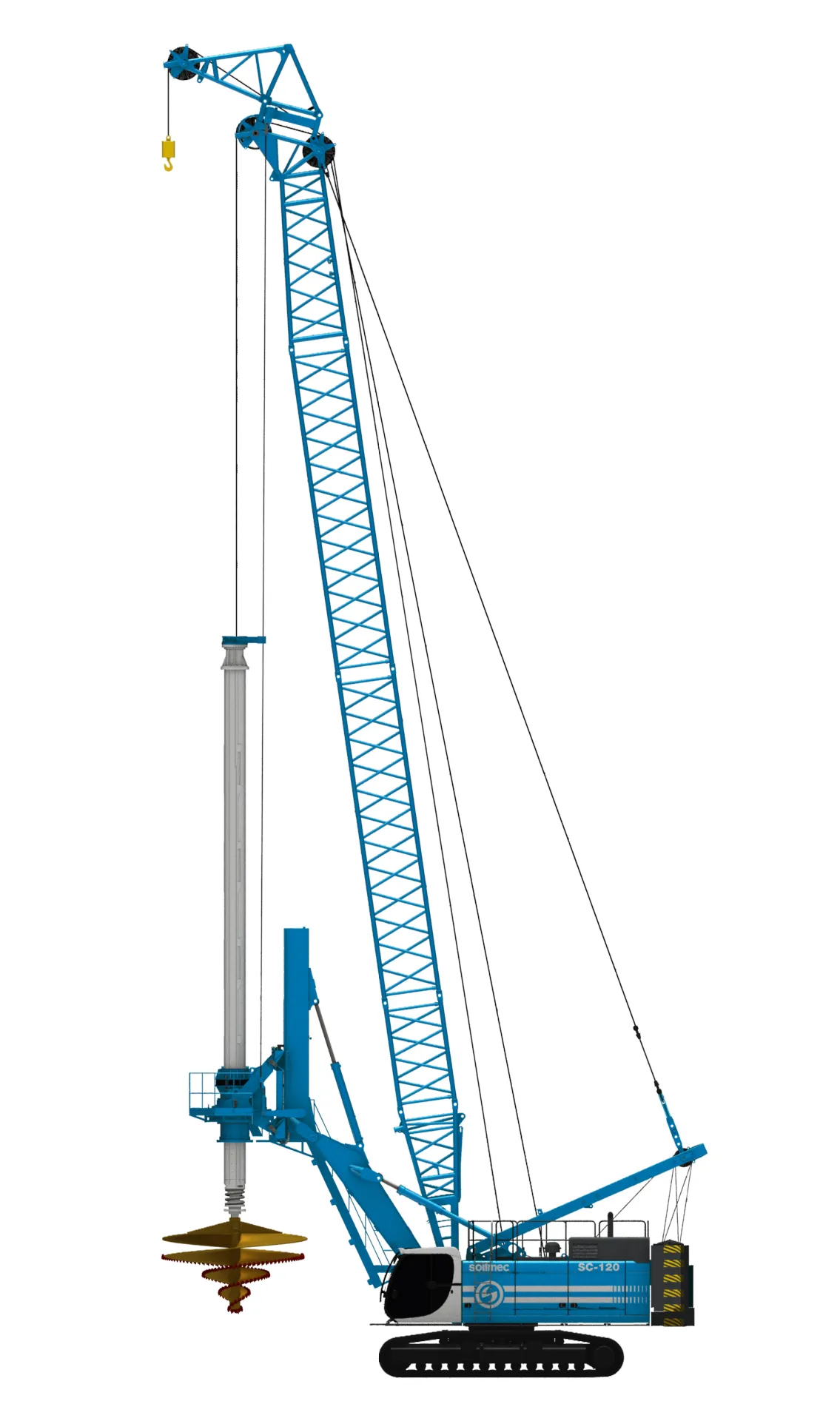

The 640 HD is a new duty cycle crawler crane for numerous applications such as well digging, underground engineering, mining and normal crane duties. Because of the 640 HD’s “robust construction, powerful multi-circuit hydraulic system, and strong slewing drive, the 40 tonne duty cycle crawler crane is particularly well-suited for special civil engineering work,” says the company.

“Applications with leaders or rope grapples can be achieved with the same high level of reliability that is offered for operation of hydraulic casing oscillators in the areas of well digging or underground engineering.”

It offers “a safe working load of 120tonnes, a proven boom concept, and a high level of flexibility,” says the company. The machine has extended the maximum safe working load of Sennebogen’s telescopic crane range by more than 50%. “Thanks to multi-cylinder technology, this maintenance-free boom system enables continuous telescoping and is always friction-locked,” says Sennebogen.

The 640 HD is a new duty cycle crawler crane for numerous applications such as well digging, underground engineering, mining and normal crane duties. Because of the 640 HD’s “robust construction, powerful multi-circuit hydraulic system, and strong slewing drive, the 40 tonne duty cycle crawler crane is particularly well-suited for special civil engineering work,” says the company.

“Applications with leaders or rope grapples can be achieved with the same high level of reliability that is offered for operation of hydraulic casing oscillators in the areas of well digging or underground engineering.”