Sometimes, the decision to embrace autonomous solutions on a construction site is rooted in safety. Such was the case for Brazil-based Construtora Barbosa Mello (CBM), which has been integral to developing Brazil’s infrastructure for more than 60 years.

Already the region’s top user of Global Navigation Satellite System technology, the engineering/construction company made a conscious decision to leverage autonomous technology. For CBM, that meant embracing aerial photography and 3D-guided machine control to compete amid global challenges from labor shortages, shorter timelines and tighter margins.

This shift would become invaluable when the company was contracted by a mining company to work in some precarious conditions throughout Brazil. For this project, CBM partnered with SITECH® Central Brazil to facilitate a digital transformation that would enable materials removal without risking operator safety.

Thinking Outside the Cab

Instead of being inside the machines on the jobsite, operators worked from a remote control center, located about 1 km from the sites. Within these shelters, the operators drove the excavation and materials loading just like they would normally, except in front of monitors,” said CBM project manager Guilherme de Souza Bechara.

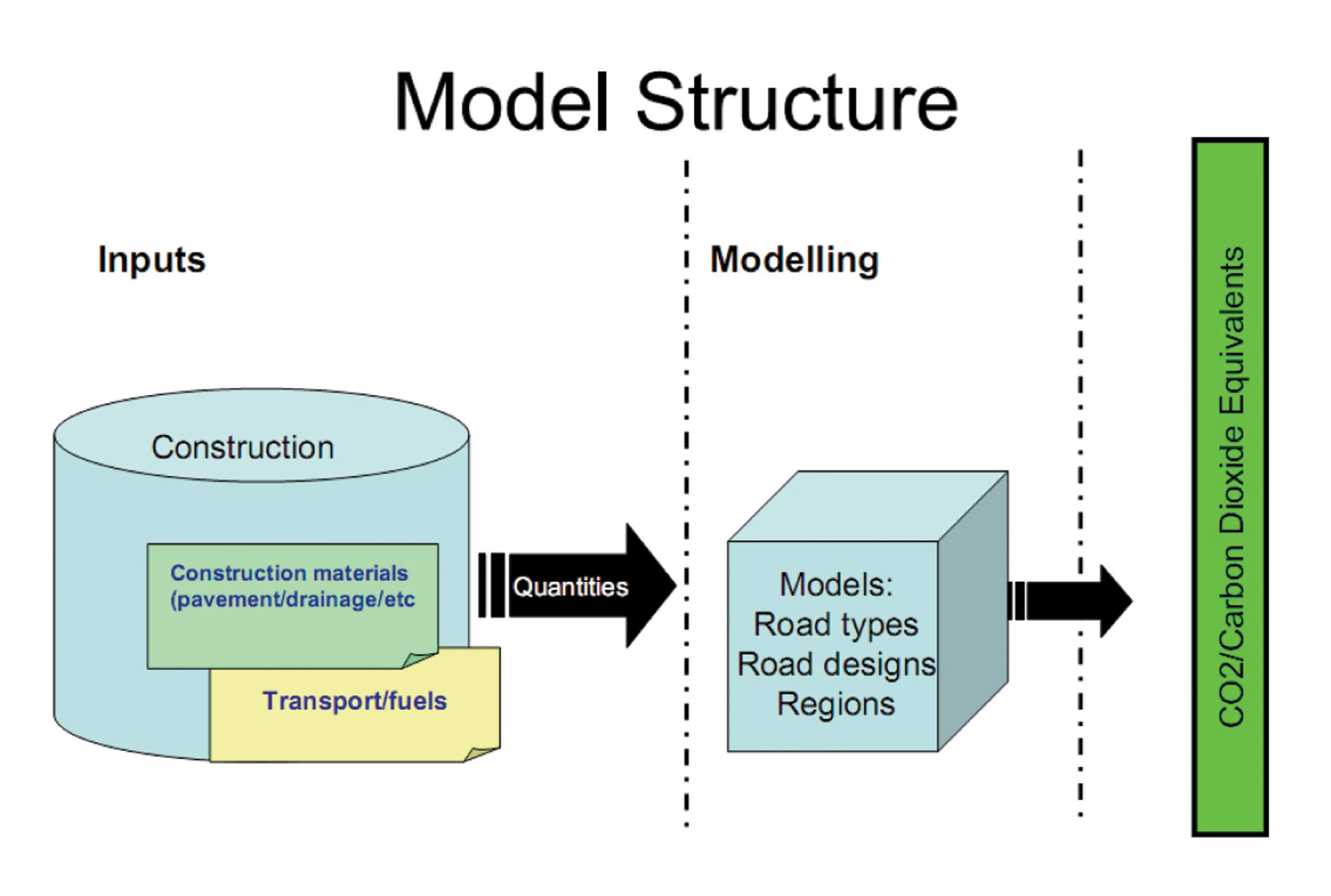

The solution incorporated four key components:

- A local network to allow remote control of the machines; transmit design data to the machines; and deliver GNSS corrections to the machines

- Trimble Stratus drone mapping and analytics platform

- A control center for remote operation of unmanned equipment

- 3D controlled equipment

Centimeter Accuracy—With a Bird’s Eye View

Rather than risk crew safety using conventional mapping methods to set five or six points on the ground with base stations, CBM opted for the Trimble® Stratus drone mapping and analytics platform. “We’ve found that the aerial photogrammetry method is safer, faster and just as accurate,” Bechara said.

By equipping excavators, dozers and motor graders with 3D guided machine control systems (either Trimble GCS900 or Trimble Earthworks), up to 17 operators could work the controls at one time. If there was any challenge for the operators, it was getting used to controlling heavy machinery with a joystick, but the system was “very intuitive,” said Bechara.

With the process now firmly in place, CBM plans to add additional semi-autonomous operations.

“Remember, we don’t have any other way to do this job safely,” Bechara added. “That technology is the enabler.”

Let Trimble guide you to the next step on your path to better. We’ll meet you where you are to take you where you’re going. Learn more at https://autonomy.trimble.com/construction.

Read the full CBM customer story here https://heavyindustry.trimble.com/resources/customer-stories/brazilian-contractor-initiates-semi-autonomous-operations-in-high-risk-areas.

Sponsored content produced in association with Trimble